Self-positioning Technology of Plate Bridge Waveguide

A self-positioning and electric bridge technology, applied in the direction of manufacturing tools, metal processing equipment, shearing devices, etc., can solve the problems of shortened service life, long production cycle, large cavity welding deformation, etc., to improve service life, prevent Strong corrosion resistance and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

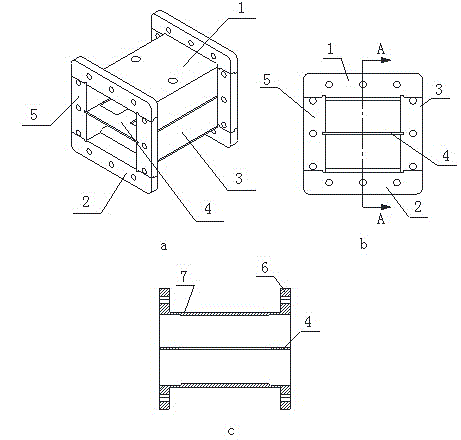

[0043] Such as figure 1 Shown is a slab bridge waveguide fabricated according to the process of the present invention. The plate bridge waveguide self-positioning process includes the following steps:

[0044] (1) Prepare raw materials and complete the preliminary processing of each part of the plate bridge waveguide, including the processing of the upper end plate 1, the processing of the lower end plate 2, the processing of the partition 4, the processing of the left wall plate 5 and the processing of the right wall plate 3 Processing, the flange 6 is respectively formed on the upper end plate 1, the lower end plate 2, the left wall plate 5 and the right wall plate 3;

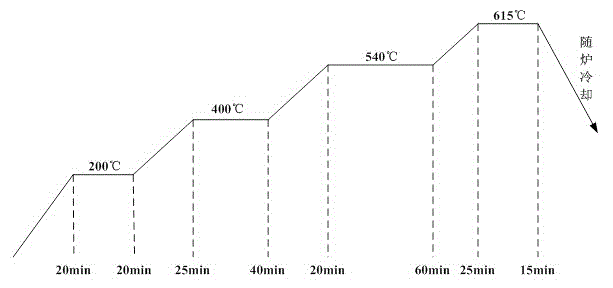

[0045] (2) Pickle the processed parts separately to remove impuriti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com