Separate combined type splay saddle and installation method thereof

A scattered cable saddle and combined technology, which is applied in the field of split combined scattered cable saddle and large tonnage scattered cable saddle, can solve the problem of the safety and reliability, alignment and assembly difficulty of suspension bridge engineering affecting the service life of the scattered cable saddle. Increase in size, poor structural strength and reliability, etc., to achieve the effect of less difficulty in assembly, less difficulty in combination, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

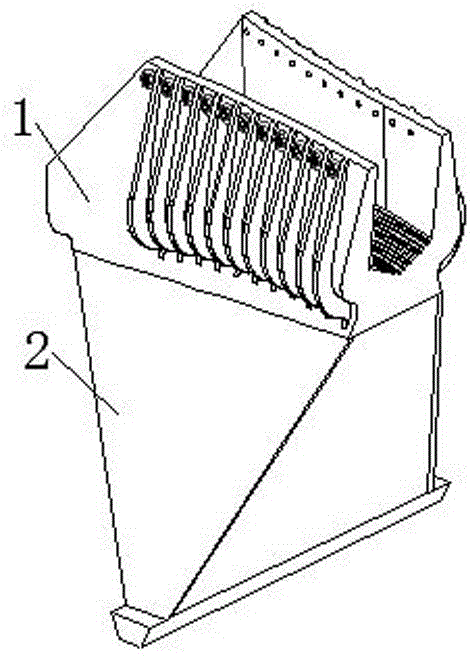

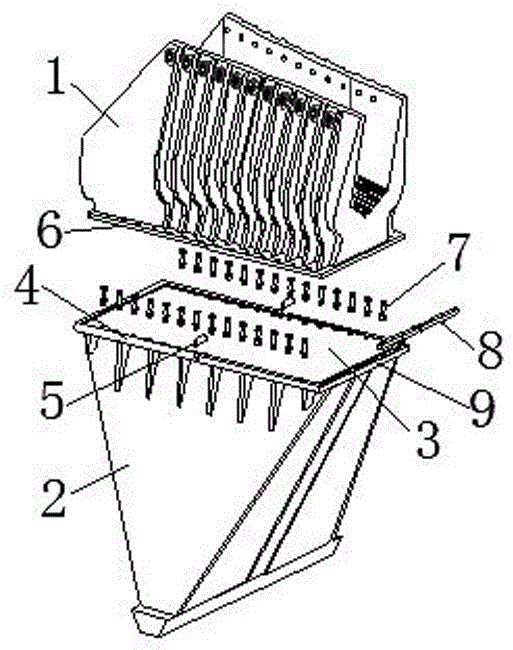

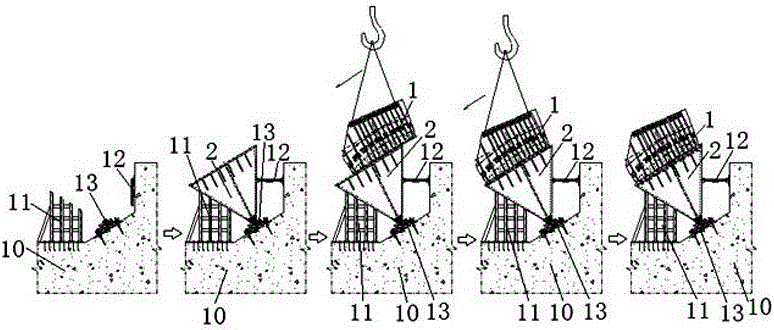

[0029] see figure 2 As shown, the present invention is a split and combined scatter saddle, which includes a saddle head 1 and a saddle body 2 of a split structure.

[0030] Wherein, the saddle head 1 is a casting structure with a saddle groove at the top and a base plate 6 at the bottom. The base plate 6 can be cast integrally with the saddle head 1 or can be a welded steel plate structure. A row of vertical bolt holes are respectively provided on the bottom plate 6 on both sides of the saddle head 1, and a horizontal positioning pin hole is respectively provided on the bottom plate 6 wall surfaces on both sides of the saddle head 1, and a horizontal positioning pin hole is respectively provided on the bottom plate 6 wall surfaces on both sides of the saddle head 1. The positioning pin holes are symmetrical.

[0031] The saddle body 2 is formed by welding steel plates, the bottom is provided with a connection structure connecting the base, and the top is provided with a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com