Power inductor core with closed magnetic circuit structure

A power inductor and closed magnetic circuit technology, applied in the field of inductors, can solve the problem that power inductor cores are difficult to achieve low power consumption, high power, simultaneous matching of production automation, poor performance of anti-EMI electromagnetic interference, and magnetic cores. It is unfavorable for mass production and use, and achieves the effects of stable inductance, improved EMI performance, and maximum power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

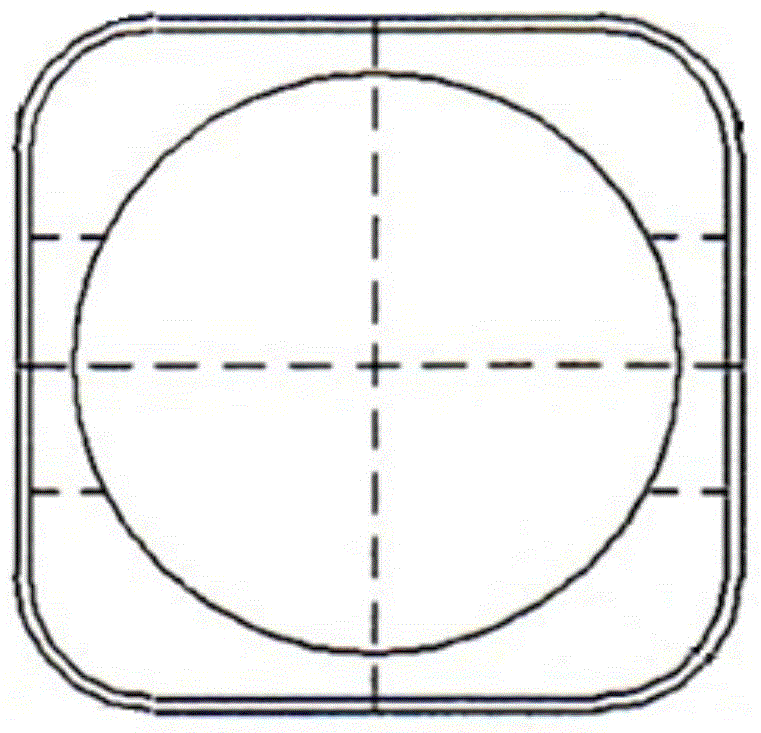

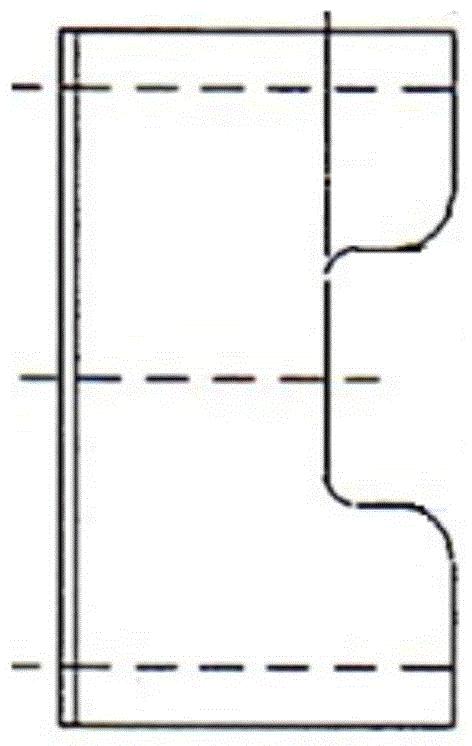

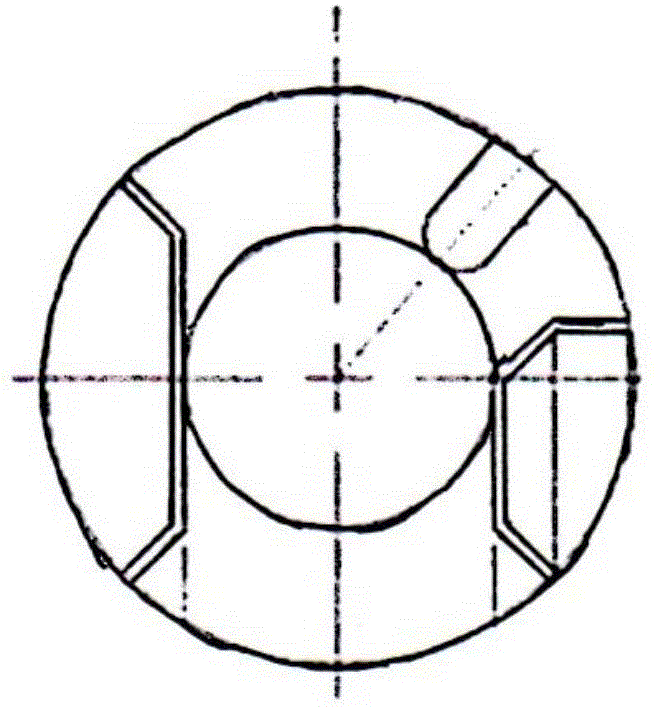

[0038] Such as Figure 2A-2C , 3A~3B and Figure 4 As shown, the magnetic core of the power inductor with the closed magnetic circuit structure of the present invention has a magnetic base 1 and a magnetic cover 2, the magnetic cover 2 is fastened on the magnetic base 1, and the central part of the magnetic base 1 is a magnetic core 3 integrated with the magnetic base , The periphery of the magnetic core 3 is a groove 4 for placing the coil.

[0039] The side of the groove 4 is provided with a notch 5 for leading out the coil wiring, and a notch 6 for installing a terminal is reserved at a position corresponding to the notch 5 on the magnetic cover 2 .

[0040] In this embodiment, the notch 6 reserved for installing the terminal is to form an electrode after the terminal and the outgoing wire are combined, so that the coil outgoing wire is connected to the terminal to facilitate welding.

[0041] The present invention uses the combined structure of the magnetic base 1 and th...

Embodiment 2

[0046] Such as Figures 5A-5B , 6A~6C and Figure 7 As shown, in order to further reduce the volume and realize the miniaturization of products, the present invention also has a second structure.

[0047] The difference between this embodiment and Embodiment 1 is that it has a magnetic base 1 and a magnetic cover 2, the magnetic cover 2 is fastened on the magnetic base 1, the magnetic base 1 is T-shaped when viewed from the side, and the central part of the magnetic base 1 protrudes It is the magnetic core 3 integrated with the magnetic base 1 .

[0048] In this embodiment, a pair of sides of the magnetic base 1 is wrapped inside the magnetic cover 2, that is, a pair of sides of the magnetic cover 2 are combined with the edge of the magnetic base 1, and the other pair of sides of the magnetic cover is provided with an outgoing line. Groove, this structure can facilitate the production process and improve production efficiency.

[0049] A pair of edge portions where the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com