Driven reel

A technology for pulling grain wheels and sprockets, which is applied in the direction of belts/chains/gears, hoisting devices, mechanical equipment, etc., which can solve the problems of easy damage to bearings and poor combination accuracy, so as to optimize the space structure, improve bearing capacity, and improve The effect of combined precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

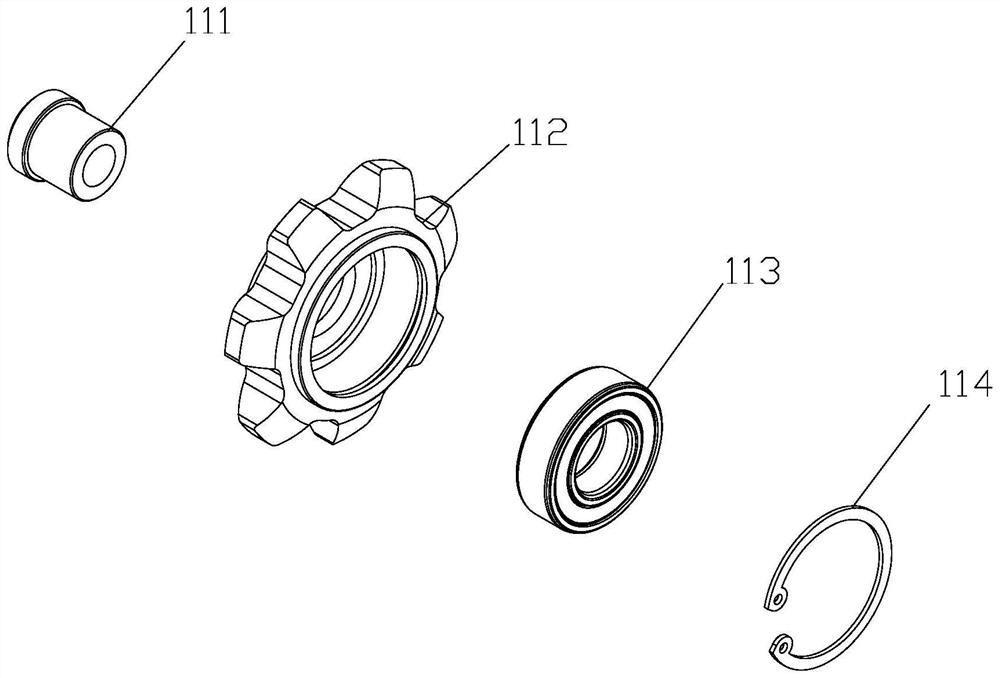

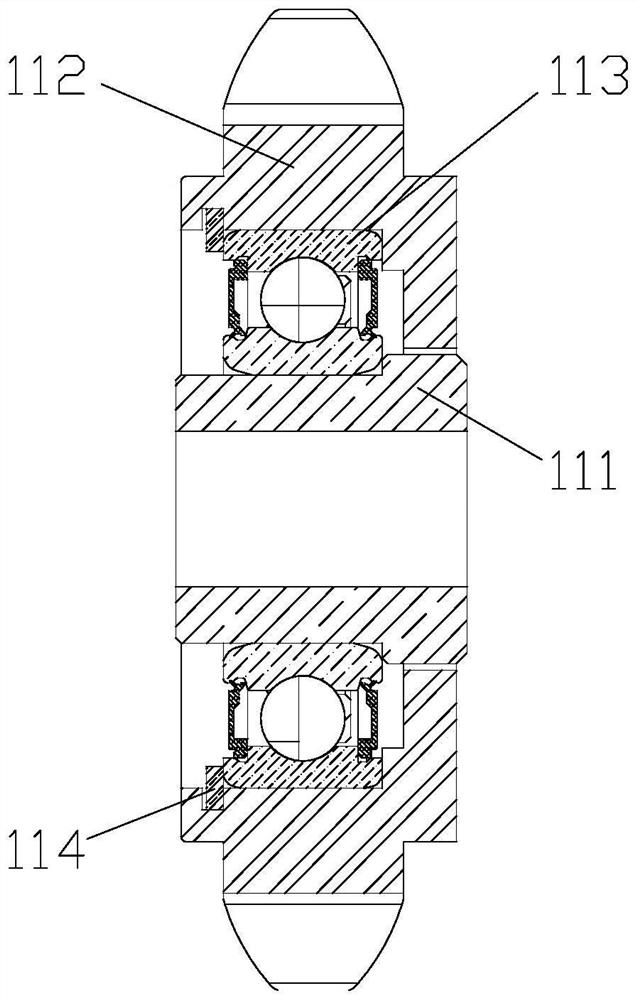

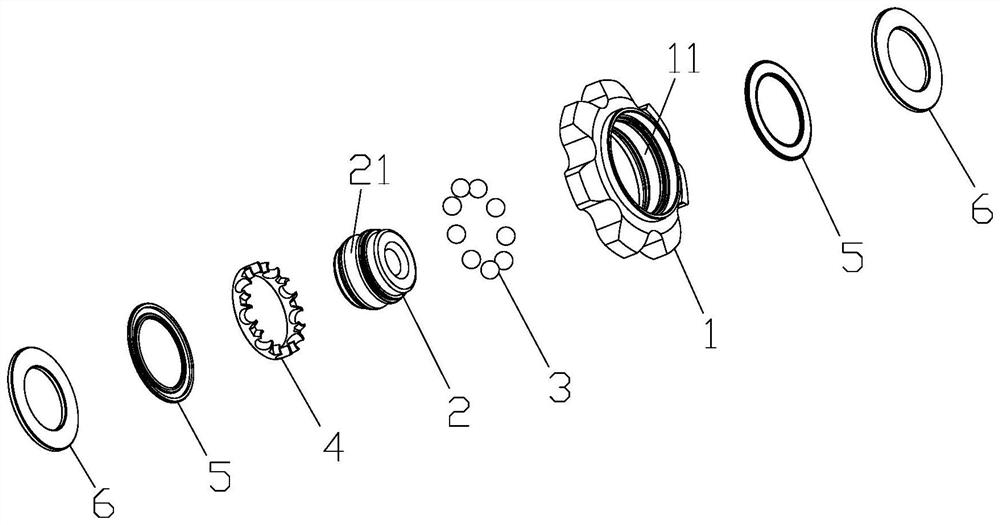

[0032] The driven pulling wheel includes the pulling wheel body, the pulling wheel body is the sprocket outer ring 1, and the inner hole wall of the sprocket outer ring 1 is provided with the first channel 11; it also includes the sprocket inner ring 2, the sprocket inner ring The outer wall of the ring 2 is provided with a second channel 21; the second channel 21 of the sprocket inner ring 2 cooperates with the first channel 11 of the sprocket outer ring 1 to form a channel space, and steel balls are placed in the channel space 3. The inner hole of the sprocket inner ring 2 is the shaft hole 9. It also includes a cage 4, which evenly separates the steel balls 3.

[0033] The reel body is transformed into the outer ring of the sprocket, that is, the structure of the outer ring of the bearing. At the same time, the inner ring of the sprocket is matched to save the bearing parts. At the same time, the channel space formed by the inner and outer rings of the sprocket is enlarged ...

Embodiment 2

[0035] On the basis of Embodiment 1, a sealing member 5 and a dustproof member 6 are arranged between the sprocket outer ring 1 and the sprocket inner ring 2 , and the dustproof member 6 is located outside the sealing member 5 . The dustproof part 6 is in interference fit with the outer wall of the sprocket inner ring 2, and is in clearance fit with the inner hole wall of the sprocket outer ring 1. A double-layer sealed and dust-proof structure is set. On the basis of the seal, a dust-proof piece 6 is added to protect the channel space. At the same time, the double-layer sealed and dust-proof structure is an independent double layer, and its strength and extrusion resistance are equal. very good.

Embodiment 3

[0037] On the basis of implementation 2, the sealing member 5 and the dustproof member 6 are in two groups, which are symmetrically arranged on both sides of the channel space. It further protects the channel space, effectively prevents the anti-mud effect of agricultural machinery, and can well block the sundries in the field from damaging the bearings, and the service life can be increased by at least 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com