Wide-flow combined type two-stage supercharger gas compressor shell based on mixed pressure spreading

A compressor casing and combined technology, which is applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as poor casting accuracy, overweight, and poor processing economy, and improve efficiency , light weight, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

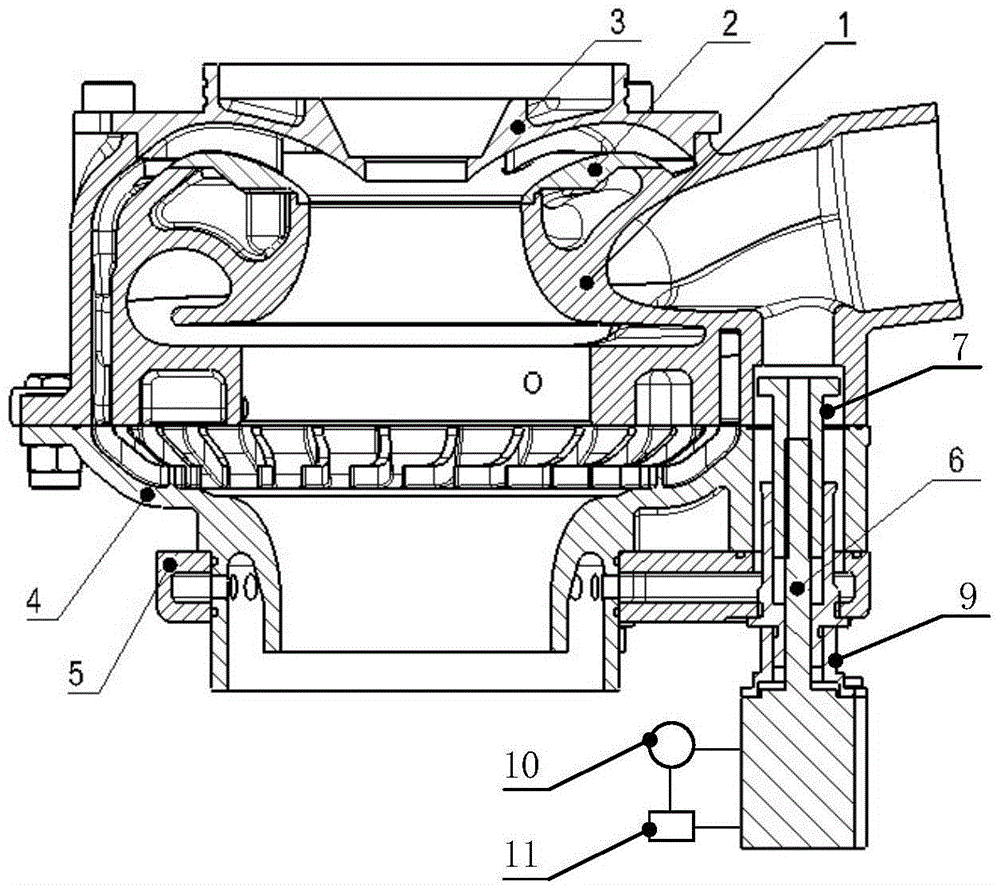

[0032] The present invention will be further described below by accompanying drawing.

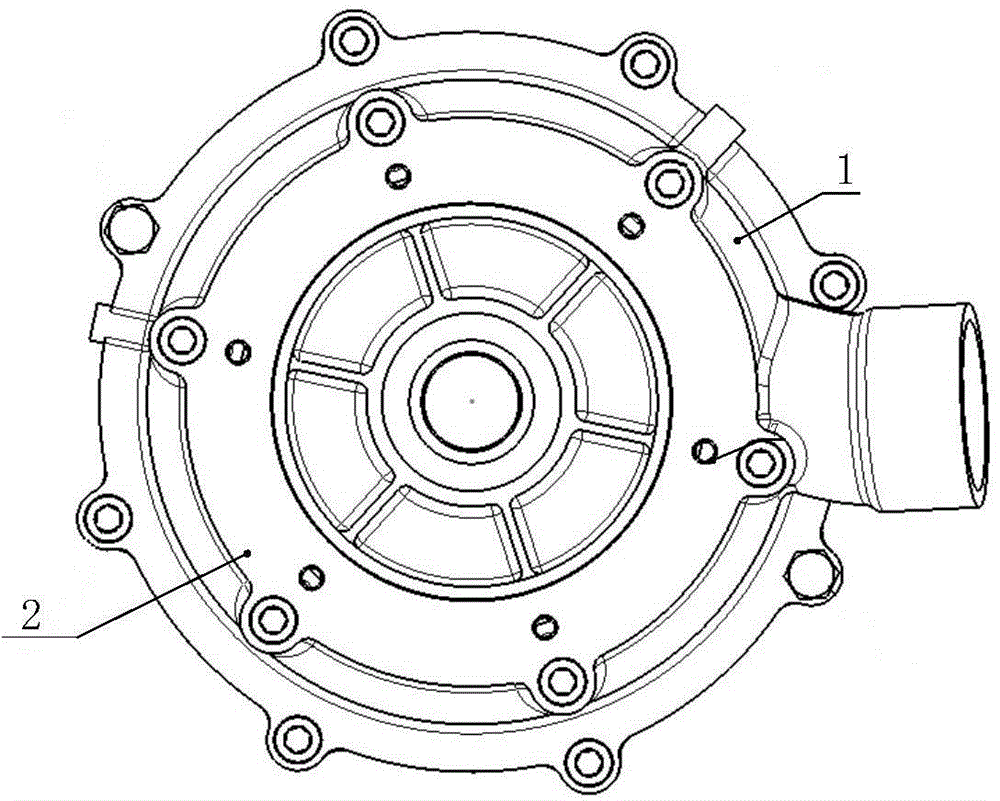

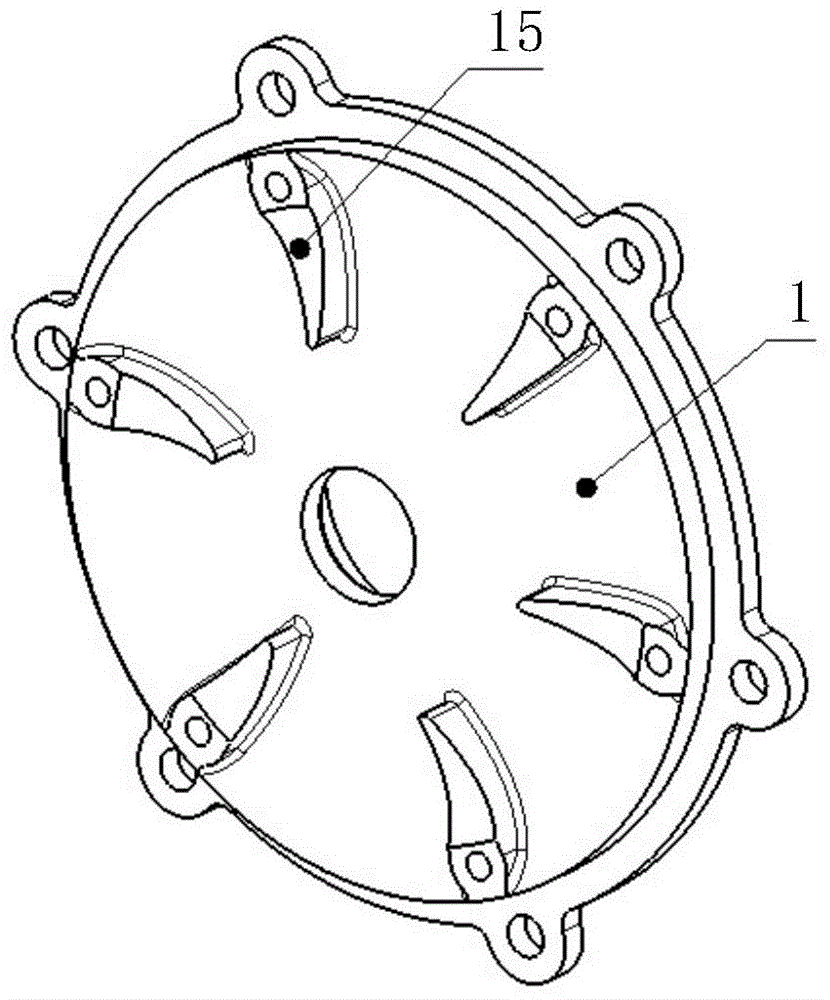

[0033] The present invention is based on the mixed and diffused wide-flow combined two-stage supercharger compressor casing, which includes a high-pressure end compressor casing assembly, a low-pressure end compressor casing assembly, and a flow regulating valve mechanical assembly. The high-pressure end compressor casing assembly includes a high-pressure compressor casing 1, the high-pressure manifold plate 2, and the compressor casing connection plate 3; the low-pressure end compressor casing assembly includes a low-pressure compressor casing 4 and a flow regulating valve seat 5; the flow regulating valve The mechanical assembly includes a flow regulating valve body 6, a plunger 7, a stepping motor bracket 8, and a stepping motor 9, such as figure 1 shown.

[0034] In the high-pressure end compressor casing assembly, the rear end of the high-pressure compressor casing 1 is designed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com