Calculus 3D (three Dimensional) constructing method and device

A construction method and calculus technology, which are applied in the field of 3D printing molding methods and devices for large and complex plastic products, can solve the problems of complex surface structure, large volume and weight, and difficult manufacturing, so as to reduce labor intensity, improve combination accuracy, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

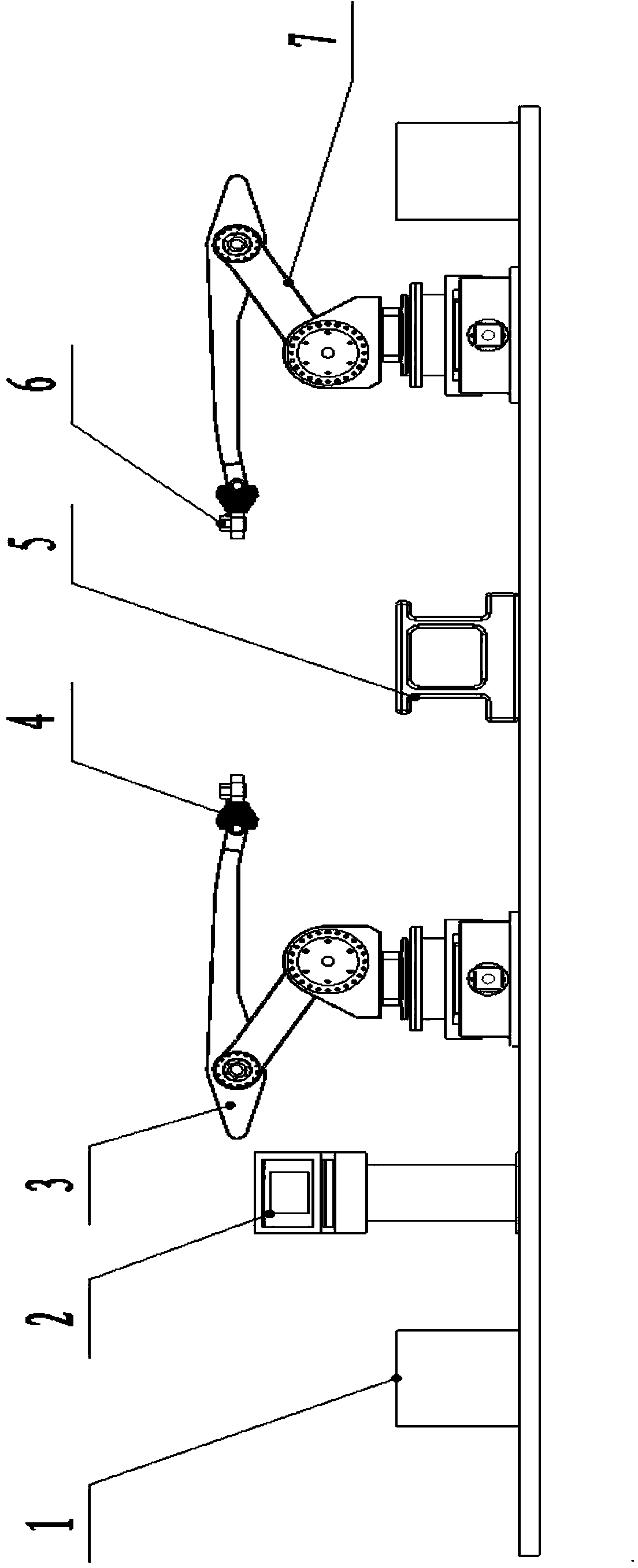

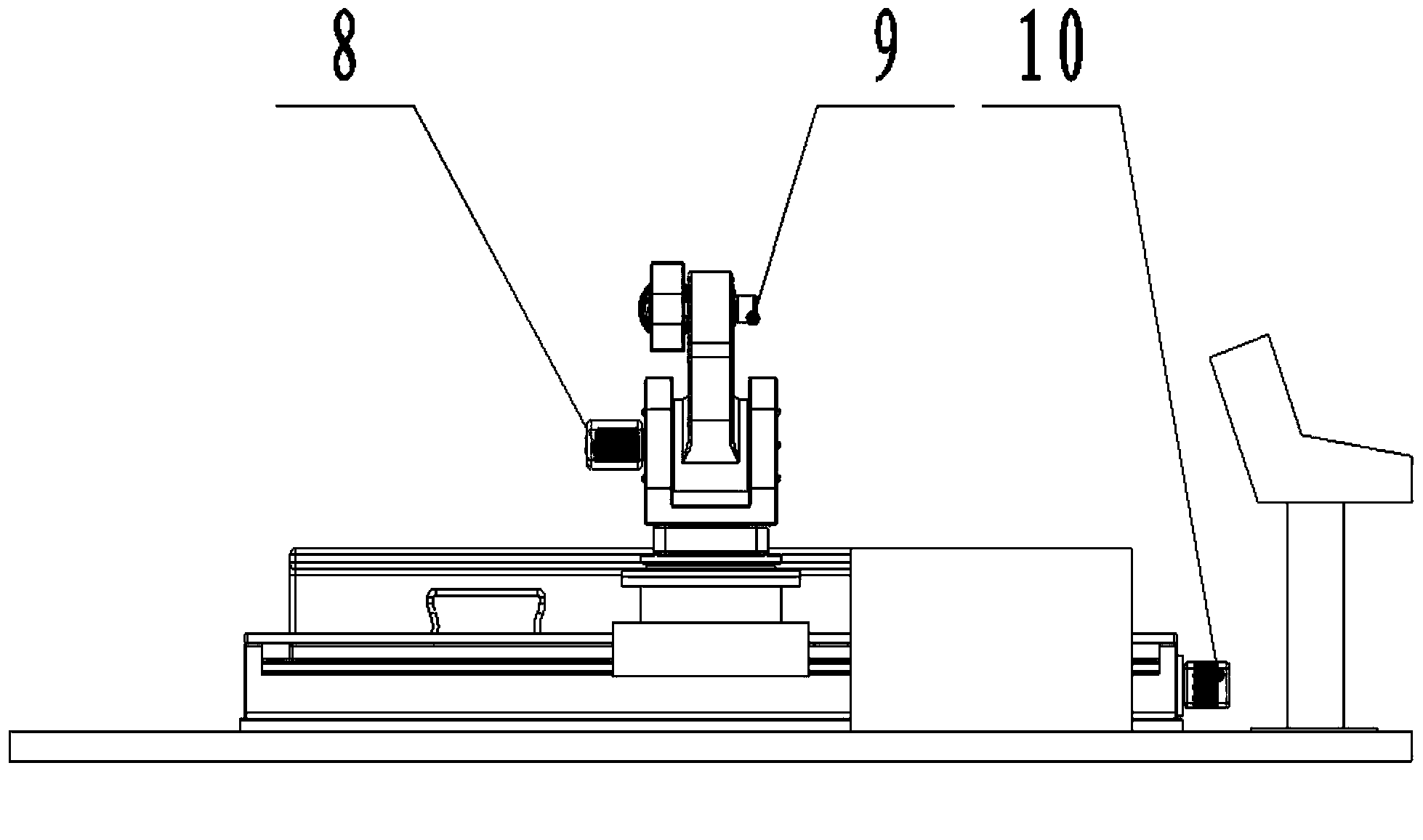

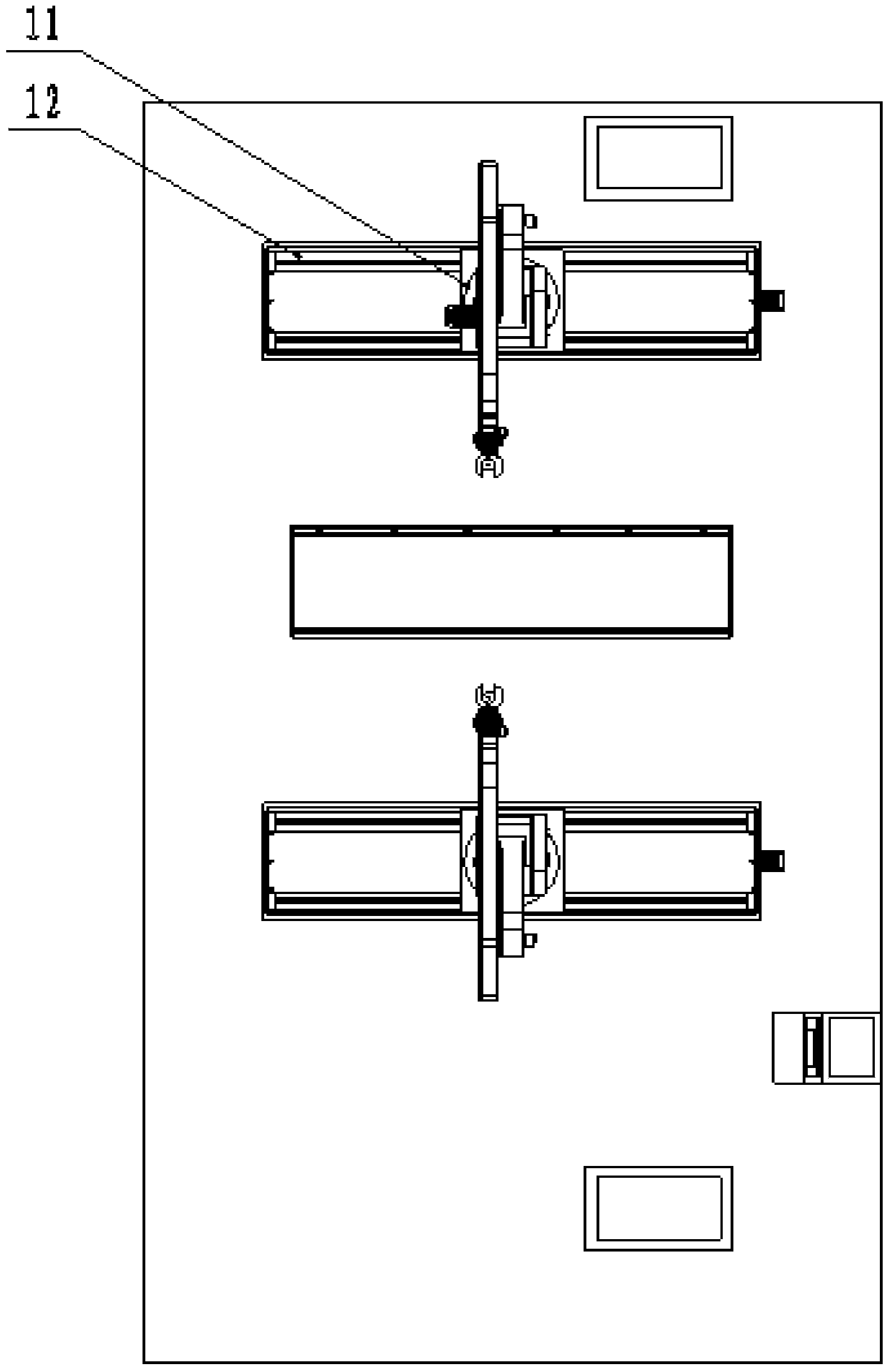

[0020] Now in conjunction with accompanying drawing, the patent of the present invention is described in detail as follows:

[0021] A calculus 3D construction method and device of the present invention, such as figure 1 , Figure 4 as well as Figure 5 As shown, firstly the pre-processed product is modeled on the computer and input to the data processing system 2, the upper mechanical arm action actuator 3 and the lower mechanical arm action actuator 7 are controlled by the data processing system 1. Clamp the polyhedron micro-unit 6 (hexagonal prism small unit is taken as an example in the figure), and then spray the adhesive on the surface of the polyhedron micro-unit evenly with the hot melt nozzle device 16 on the manipulator, and then mortise and tenon splice it on the workbench on, such as Figure 4 Shown is the rendering of part of the finished product, and the final product can be obtained by continuing 3D printing.

[0022] A calculus 3D construction device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com