Take-up lever device, link mechanism and production process of link mechanism

A connecting rod mechanism and production process technology, applied in the field of thread take-up rods, can solve problems such as low precision, low strength, and high noise, and achieve the effect of high combination accuracy, high strength, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

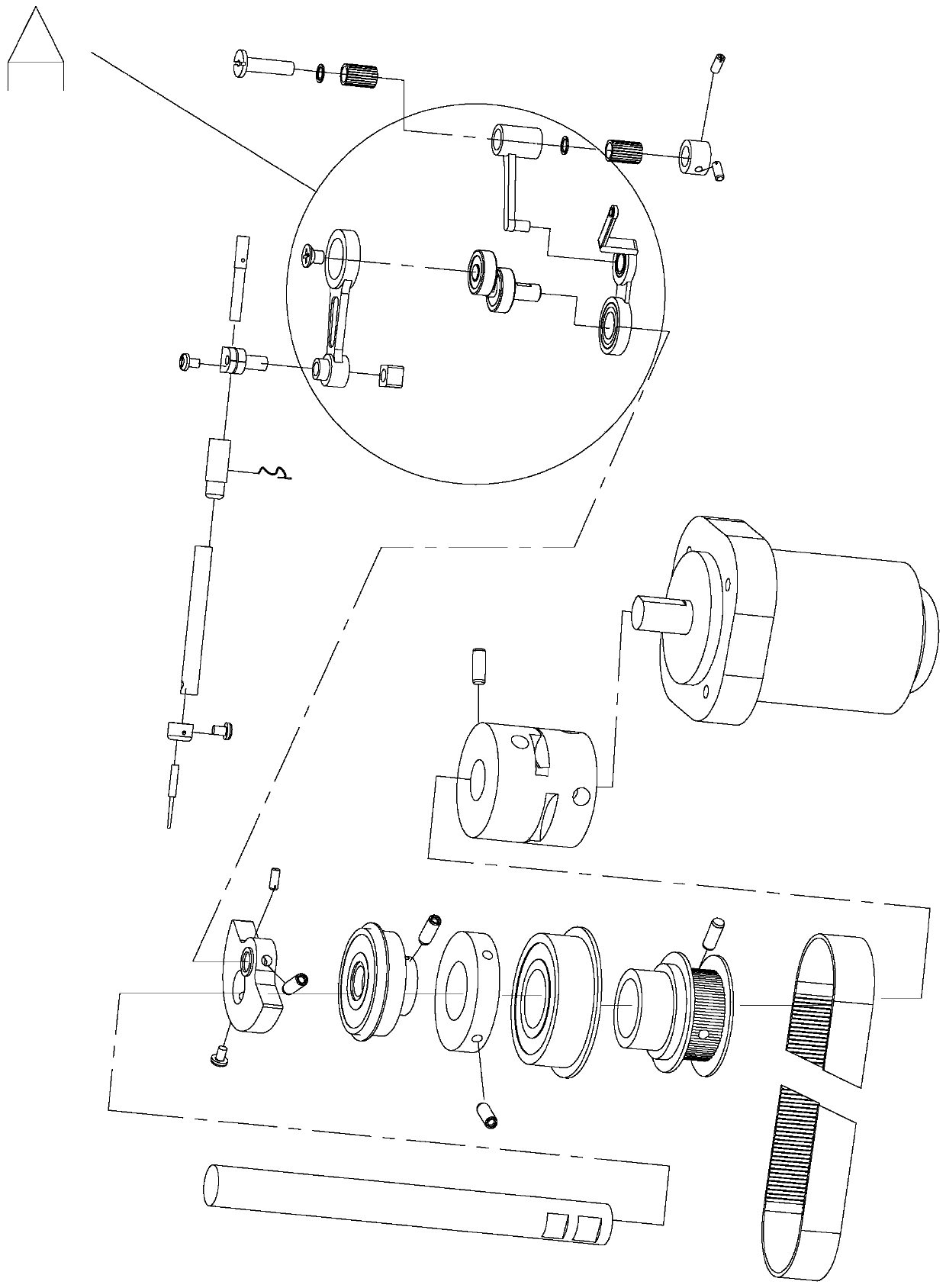

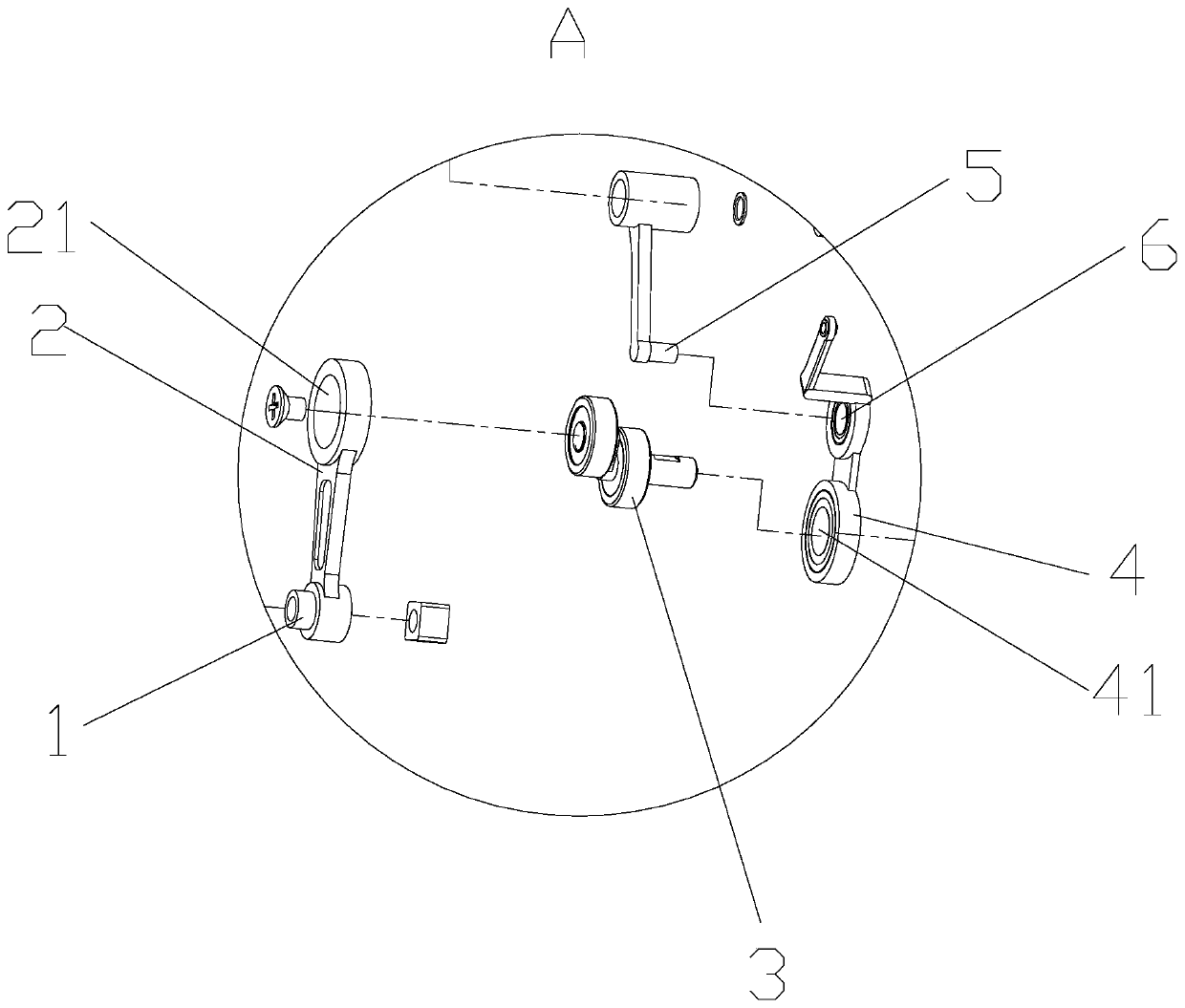

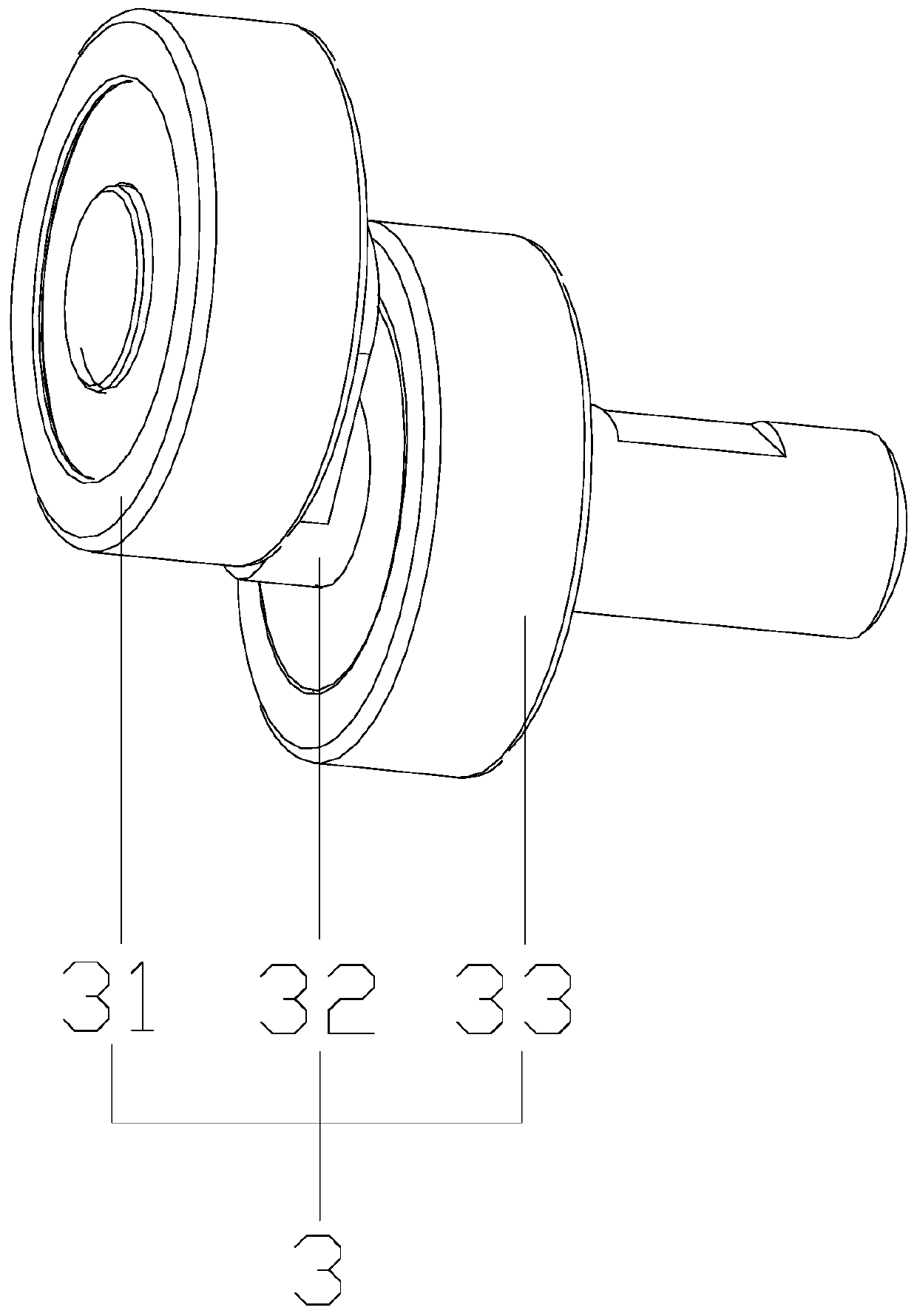

[0034] A link mechanism, as shown in the figure, includes a rolling assembly 3. The rolling assembly 3 includes a first rolling assembly 31, a special-shaped shaft 32 and a second rolling assembly 33. The first rolling assembly 31 passes through the special-shaped shaft 32 and the second rolling assembly. 33 connection, the special-shaped shaft 32 includes a first shaft body 321, a connecting block 323 and a second shaft body 322, the first shaft body 321 is connected with the second shaft body 322 through the connecting block 323, the first shaft body 321 and the second shaft body The axis lines of 322 are parallel and not collinear, the first shaft body 321, the connecting block 323 and the second shaft body 322 are in a Z shape, the first shaft body 321 is provided with a first channel 3211, and the first channel body 3211 A first ball 314 is provided, a second channel 3221 is provided on the second shaft body 322 , and a second ball 335 is provided on the second channel 322...

Embodiment 2

[0043] A thread take-up lever device, as shown in the figure, includes the linkage mechanism described in Embodiment 1.

Embodiment 3

[0045] A production process of a link mechanism, comprising the following steps:

[0046] (1) Dig out a first channel 3211 on the first shaft body 321, and put a first inner seal 315 in the first inner mounting place 3212 on the first shaft body 321;

[0047] (2) Insert the first outer ring 311 on the outer circumference of the first shaft body 321, so that the first ball 314 can enter the first channel 3211 of the first shaft body 321 and the channel of the first outer ring 311;

[0048] (3) Snap the first cage 313 onto the first ball 314, so that the first cage 313 is located between the first shaft body 321 and the first outer ring 311;

[0049] (4) Inject grease in the direction of the first outer seal 313, put the first outer seal 312 into the first outer mounting part 3213 on the first shaft body 321, cover the first outer seal 313, and use tools to The first inner seal 315 is installed into the first inner mounting place 3212;

[0050] (5) Dig out a second channel 322...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com