Preparation method of phosphorus-modified phenolic resin

A technology of phenolic resin and phosphorus modification, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., to achieve the effects of reducing environmental pollution, improving heat resistance, and excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

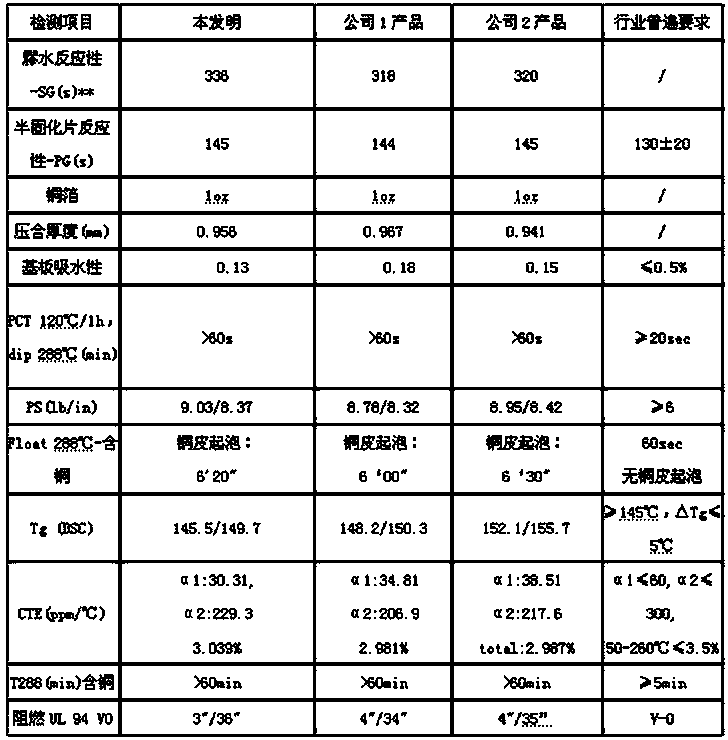

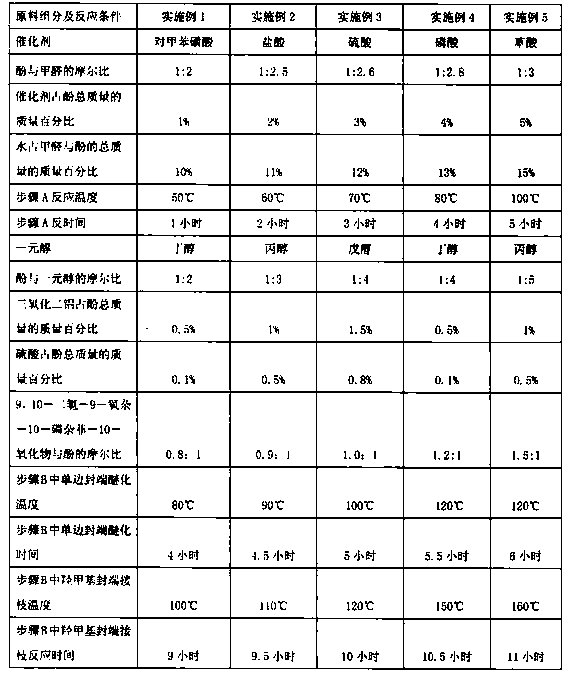

[0020] Table 1 and Table 2 are the reaction raw material components and reaction conditions in Examples 1 to 10, wherein the phenols described in Examples 1 to 10 are p-tert-butylphenol.

[0021] Prepare according to the following preparation steps in conjunction with the reaction raw material components and reaction conditions that table 1 and table 2 provide:

[0022] A. Take phenol, formaldehyde and water and add them into a four-necked flask and mix them evenly, then add a catalyst and mix them evenly, put the four-necked flask into an electric heating mantle and heat for condensation reaction to obtain a phenolic condensate, release it after cooling down, and separate it residual moisture;

[0023] B. Add the phenolic condensate obtained in step A back into the four-necked bottle, add monohydric alcohol and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and mix evenly, then add dihydrogen trioxide Aluminum and sulfuric acid are used as catalysts, the temperature is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com