Ring gasket capping machine

A ring gasket and capping machine technology, which is applied in hand-held tools and manufacturing tools, can solve the problems of unsanitary bottles and waste of laundry detergent, and achieve high production efficiency, high combination precision, and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

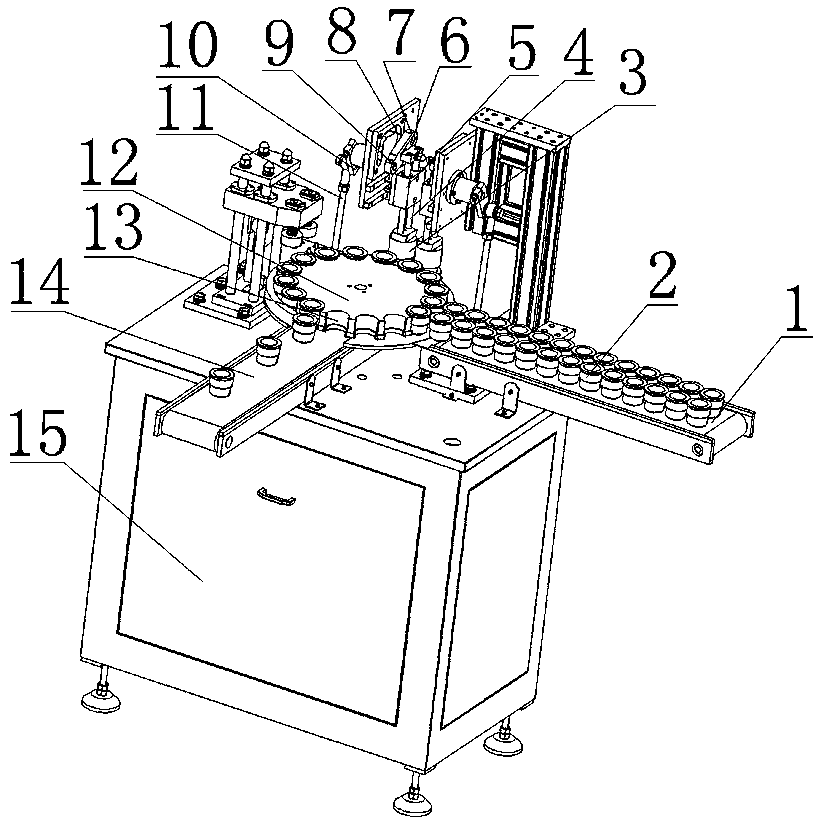

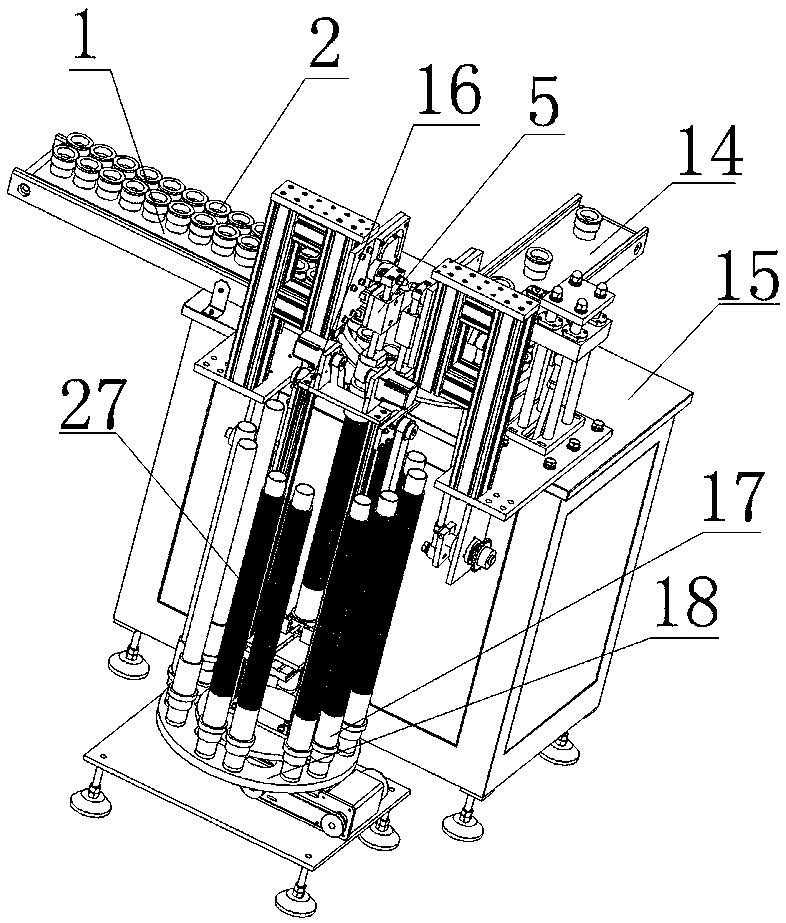

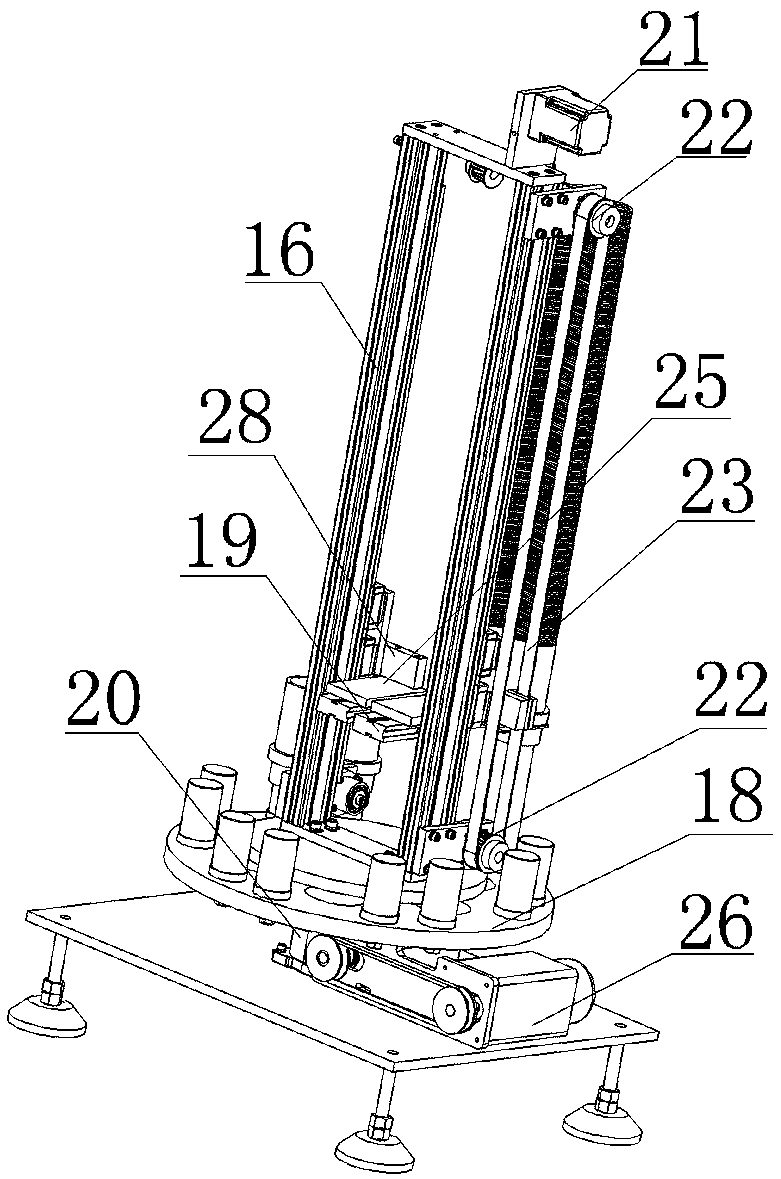

[0023] Referring to the accompanying drawings, this ring gasket capping machine includes a body 15, a bottle cap input belt 1, a bottle cap output belt 14, and a first indexing turntable 12. The bottle cap input belt 1 and the bottle cap output belt 14 are It is a flat belt, wherein the first indexing turntable 12 is driven by an indexing motor, and the circumferential surface of the first indexing turntable 12 is uniformly provided with arc grooves 13 that match the bottle cap 2, and the bottle cap 2 is flat. Lie on the bottle cap input belt 1 and keep conveying. When the bottle cap 2 reaches the circumference of the first indexing turntable 12, it will fall into the arc groove 13 on the first indexing turntable 12. With the first indexing turntable The rotation of the turntable 12 rotates to the working station. One side of the body 15 is provided with an annular gasket storage mechanism, and the annular gasket storage mechanism includes a second indexing turntable 18, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com