Patents

Literature

48 results about "Metal work function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

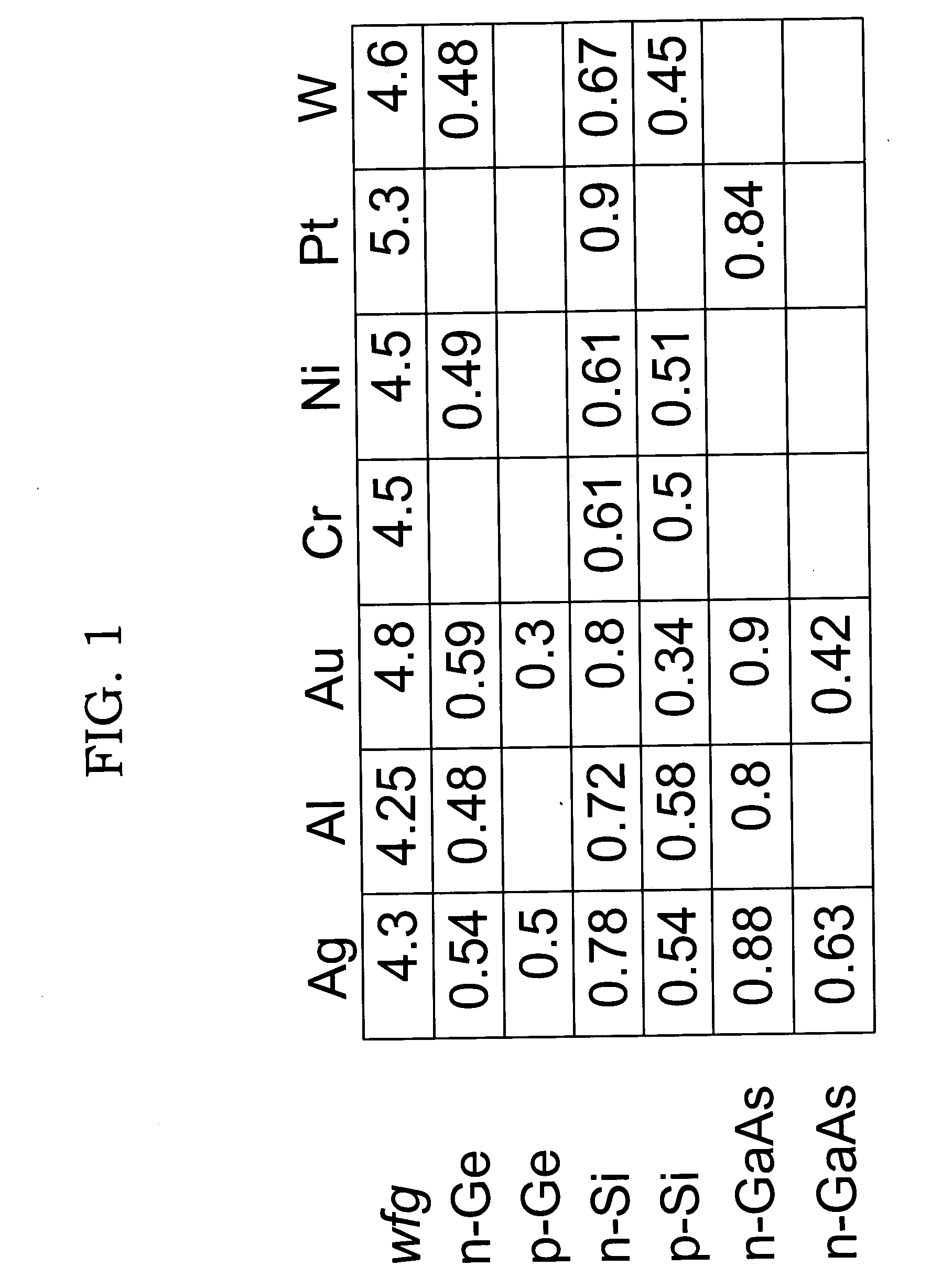

For a metal, the work function has a simple interpretation. At absolute zero, the energy of the most energetic electrons in a metal is referred to as the Fermi energy; the work function of a metal is then equal to the energy required to raise an electron with the Fermi energy to the energy level corresponding to an electron at rest in vacuum.

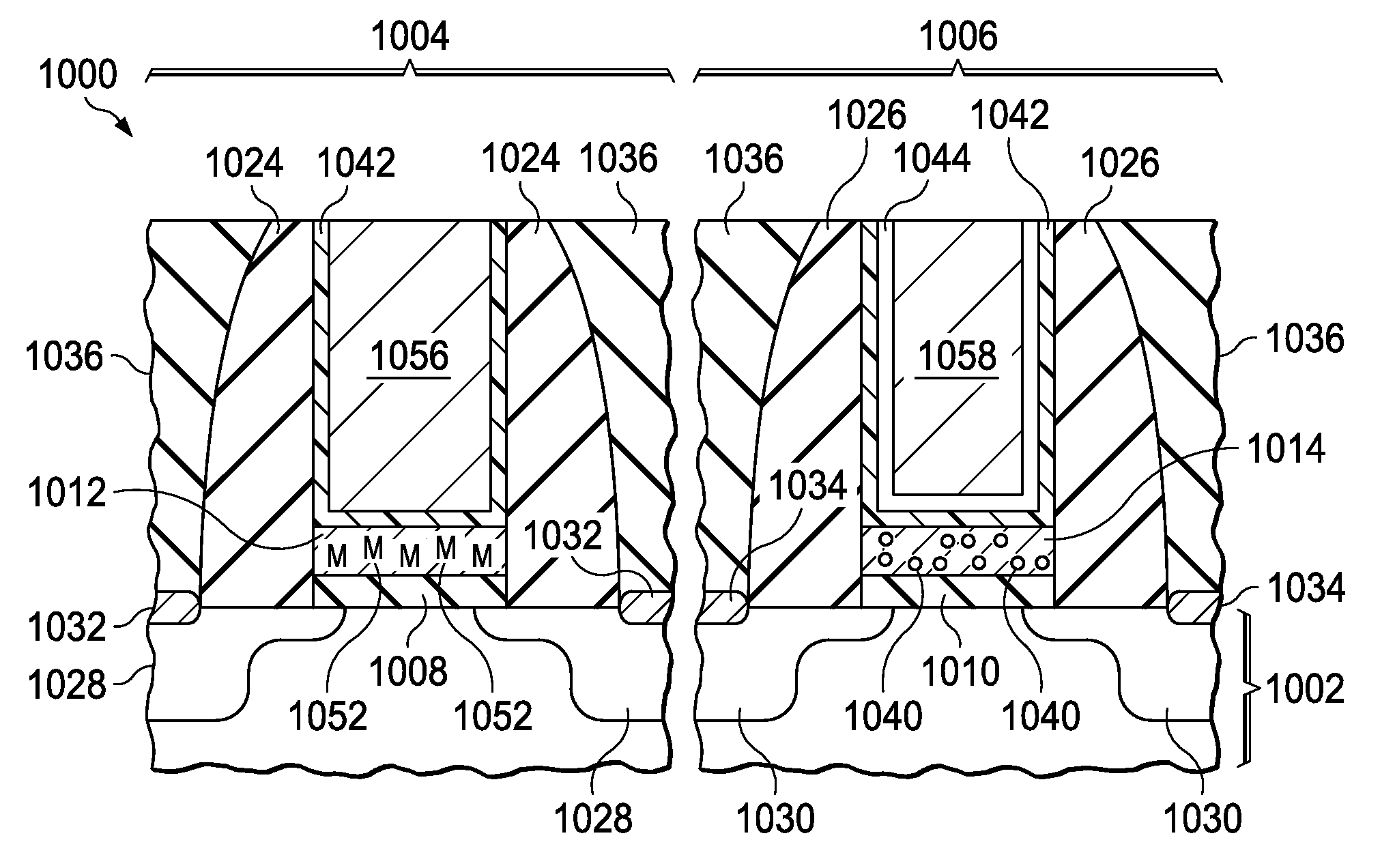

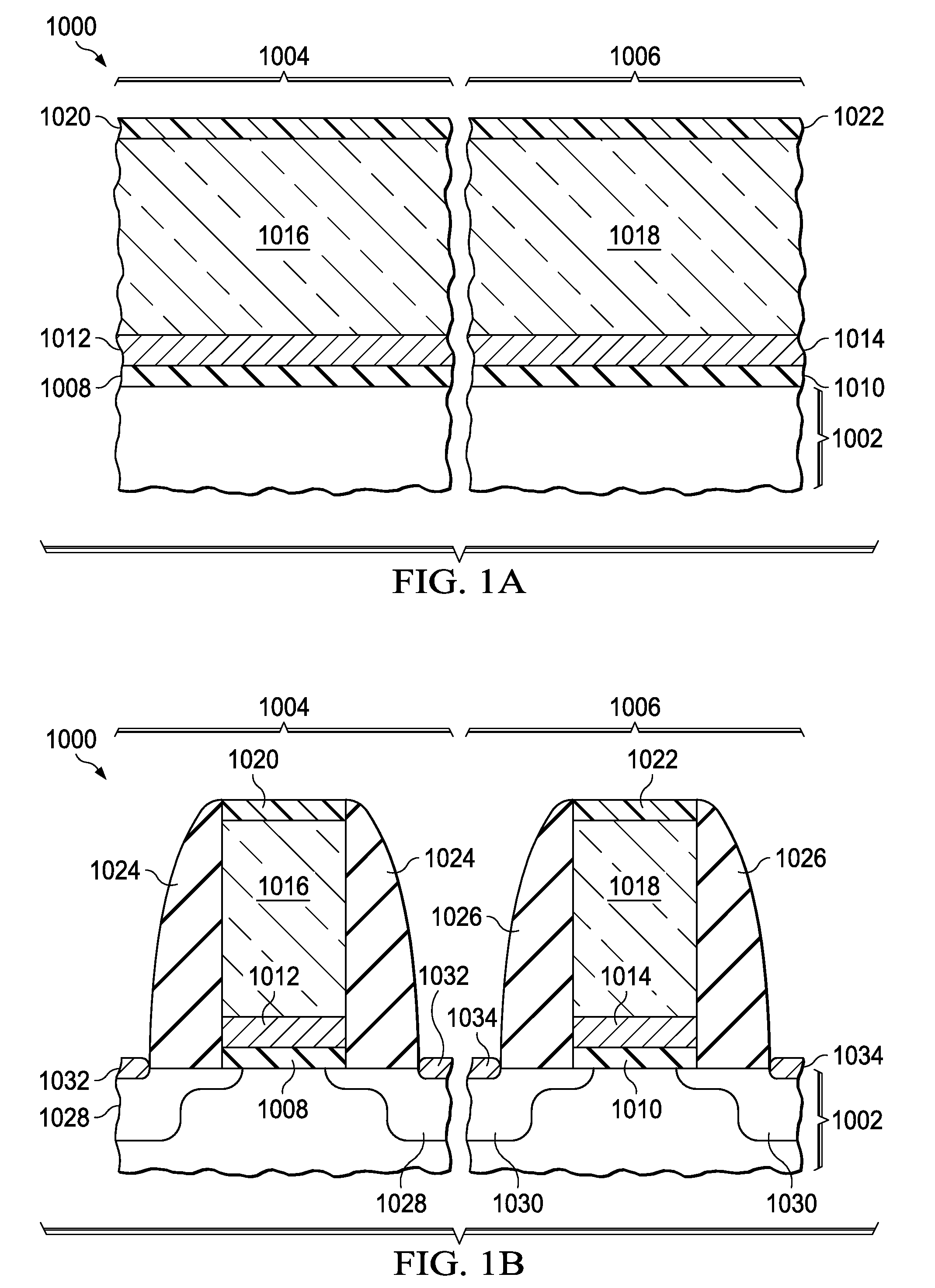

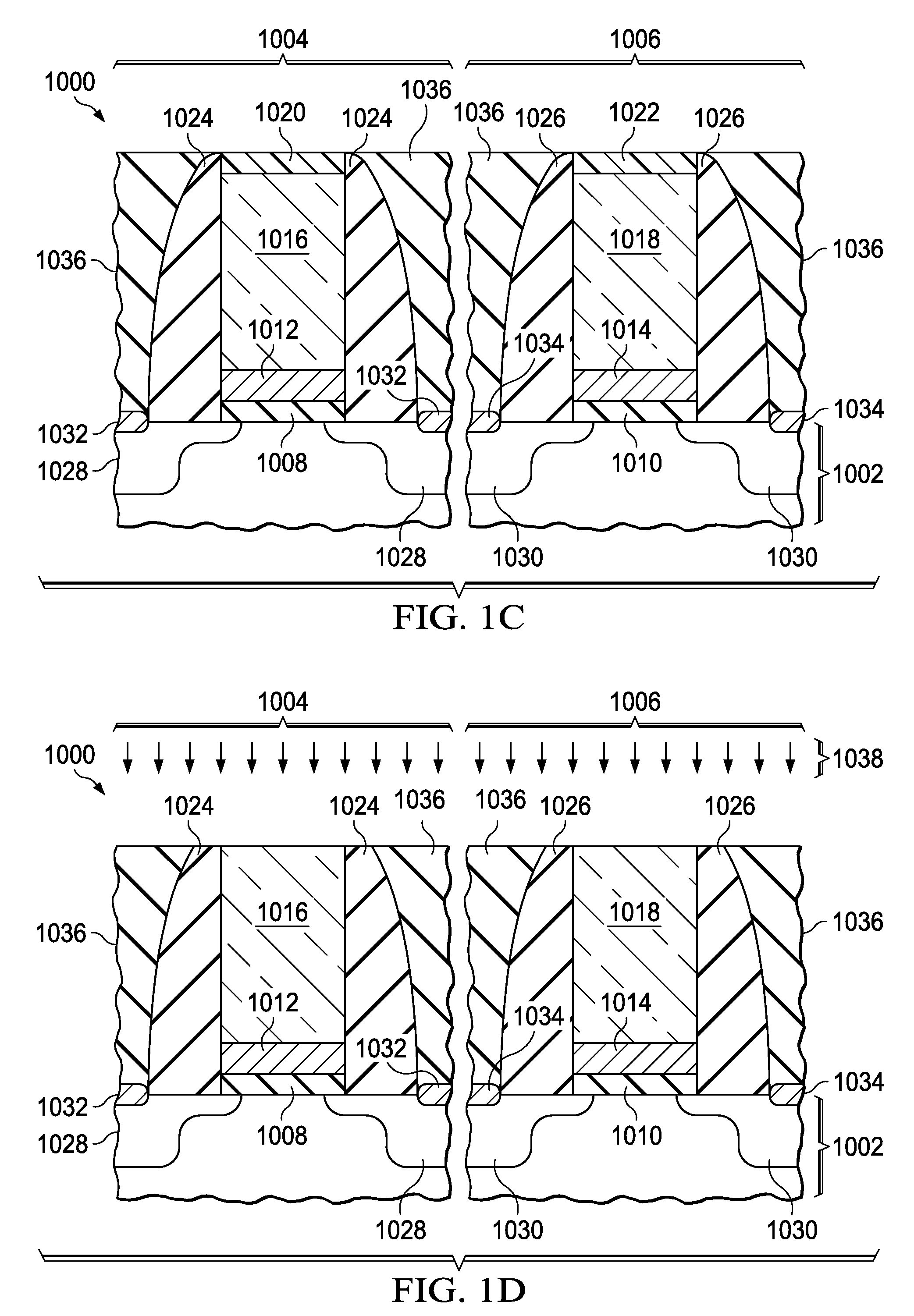

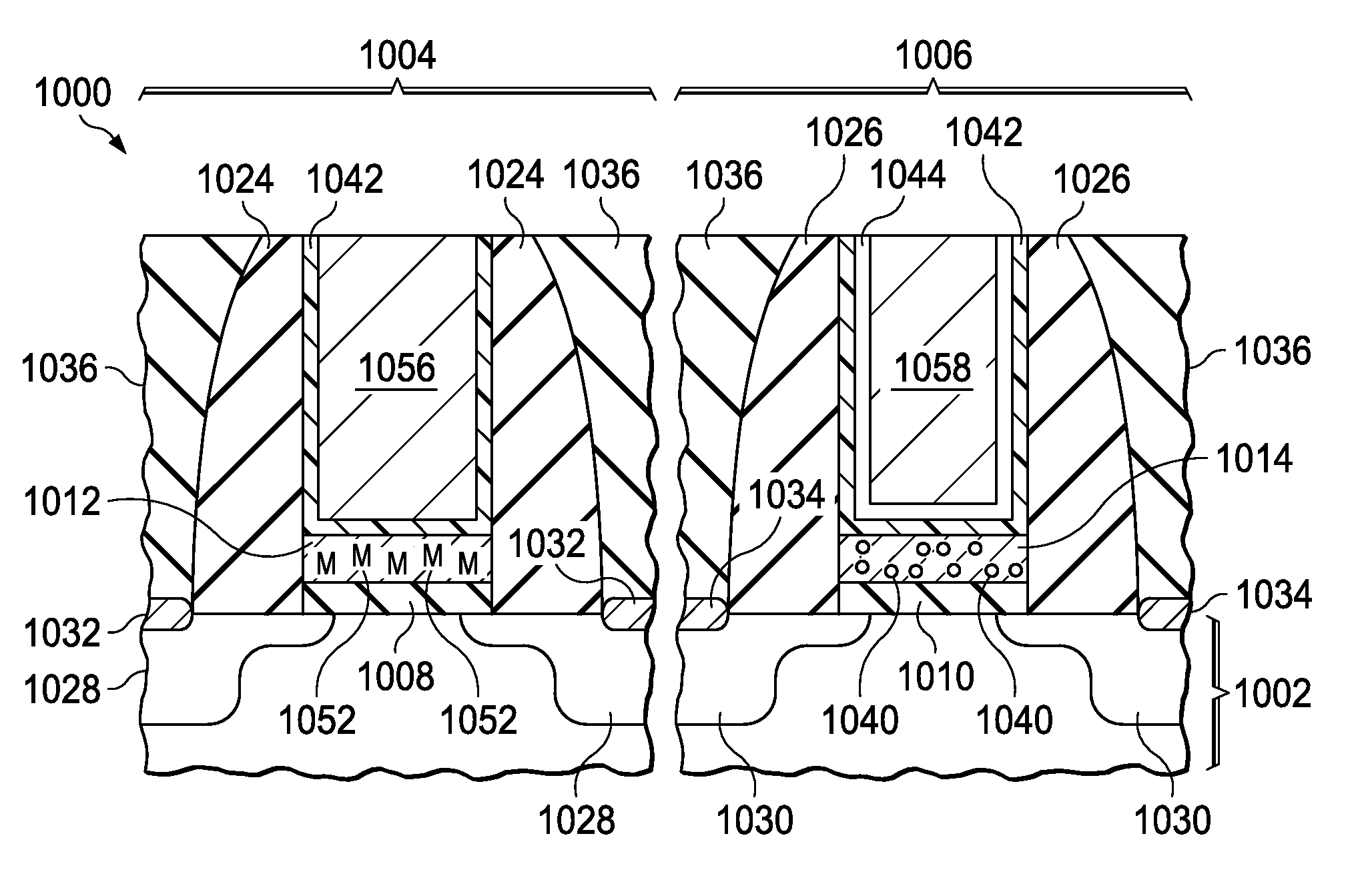

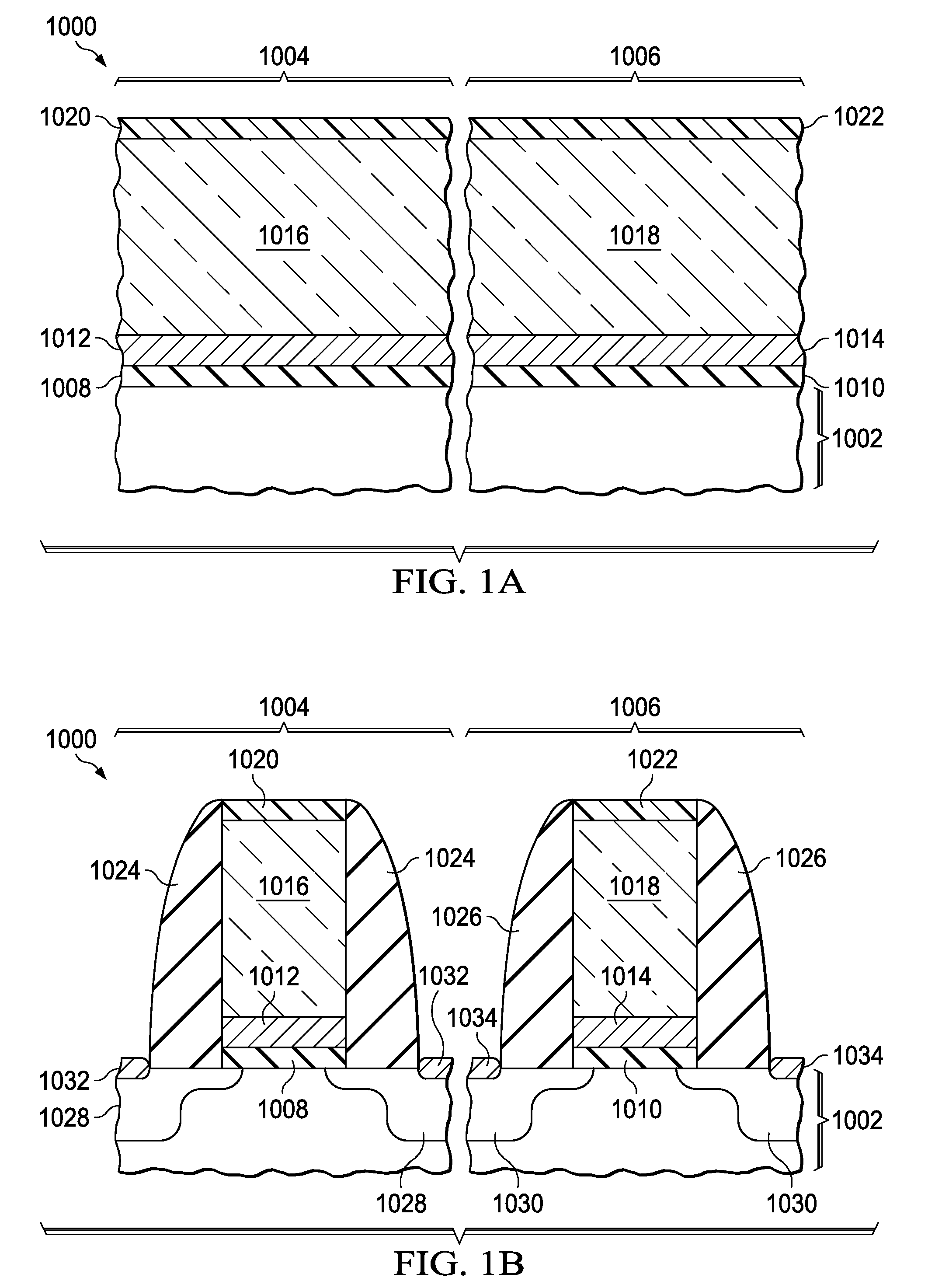

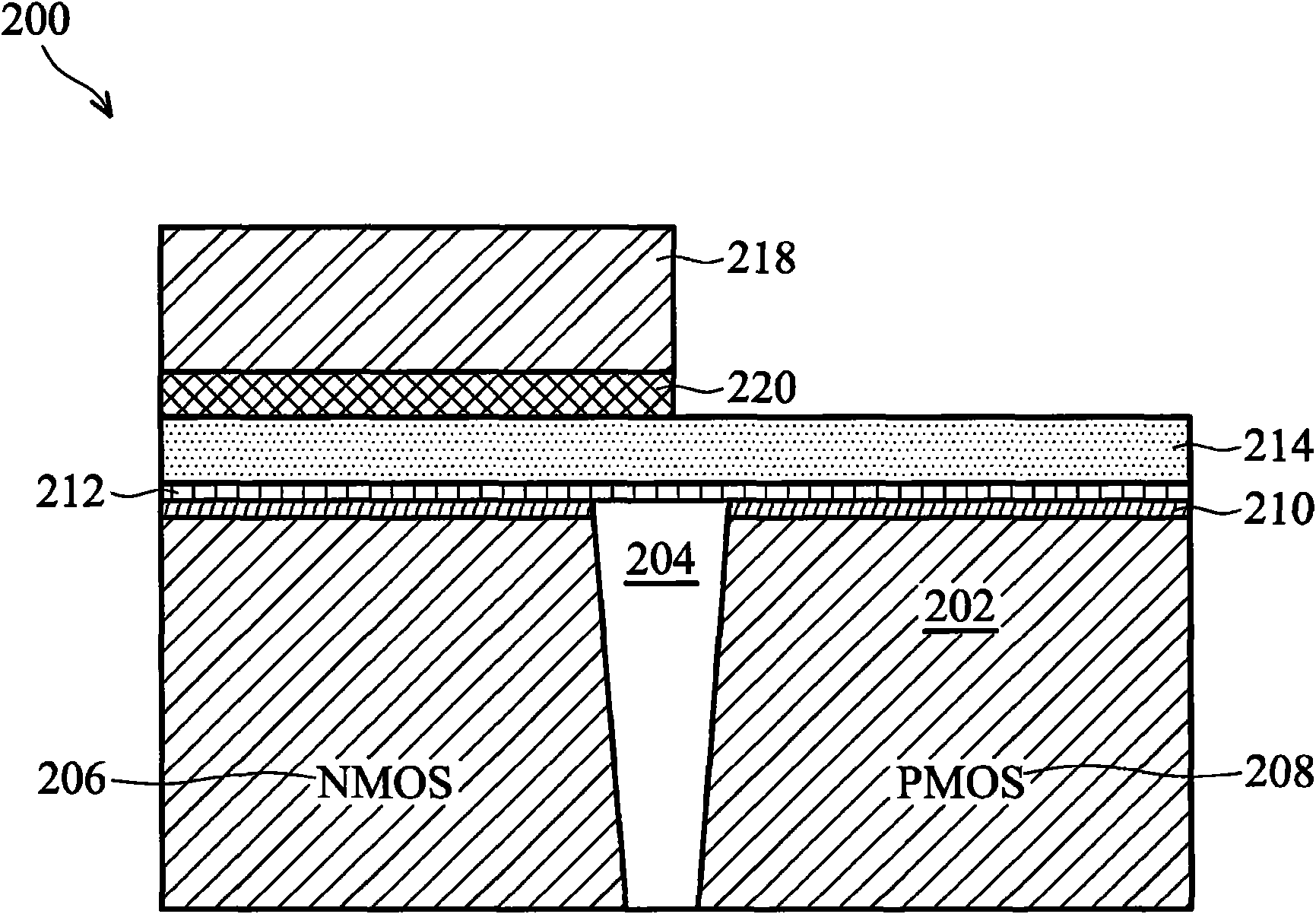

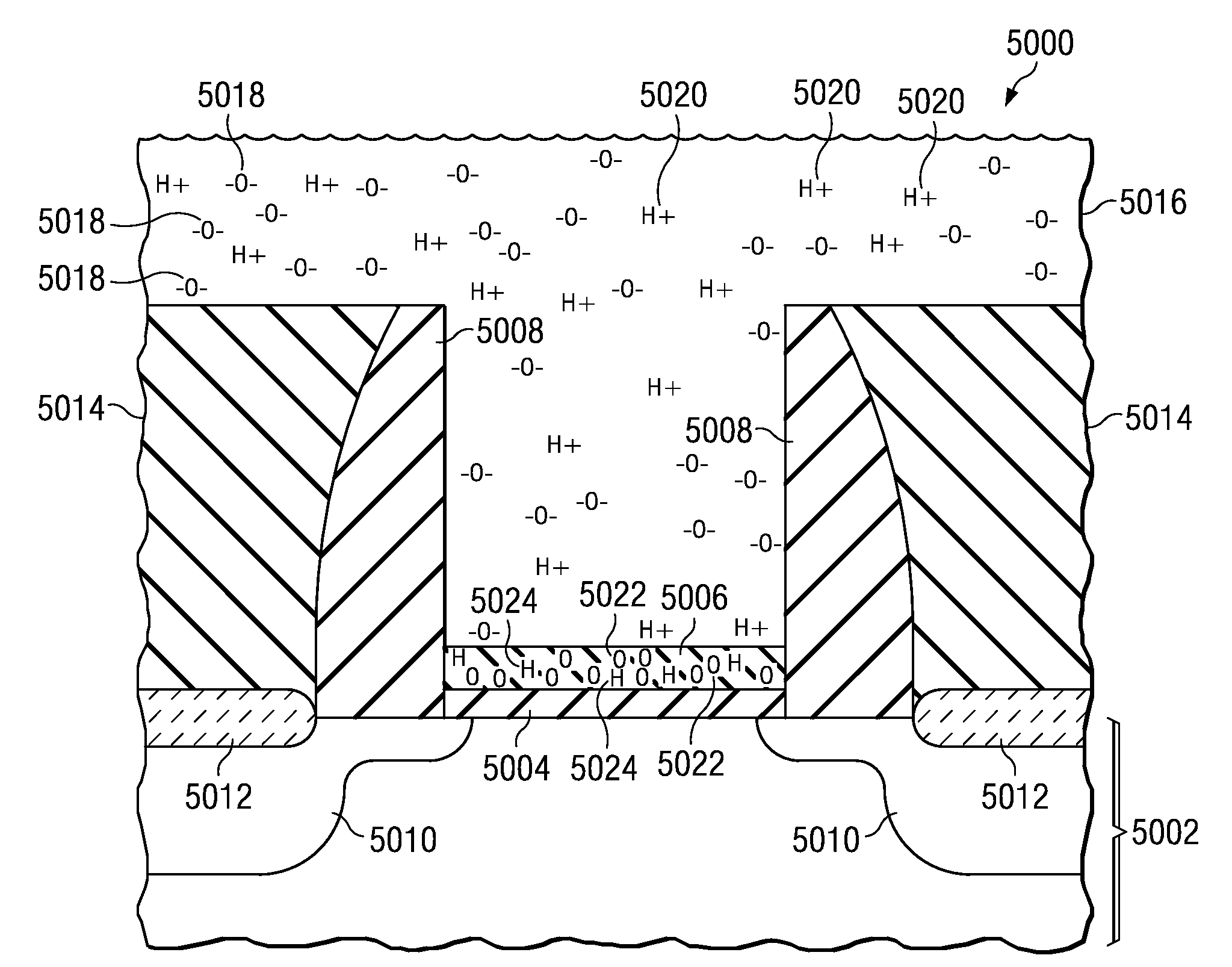

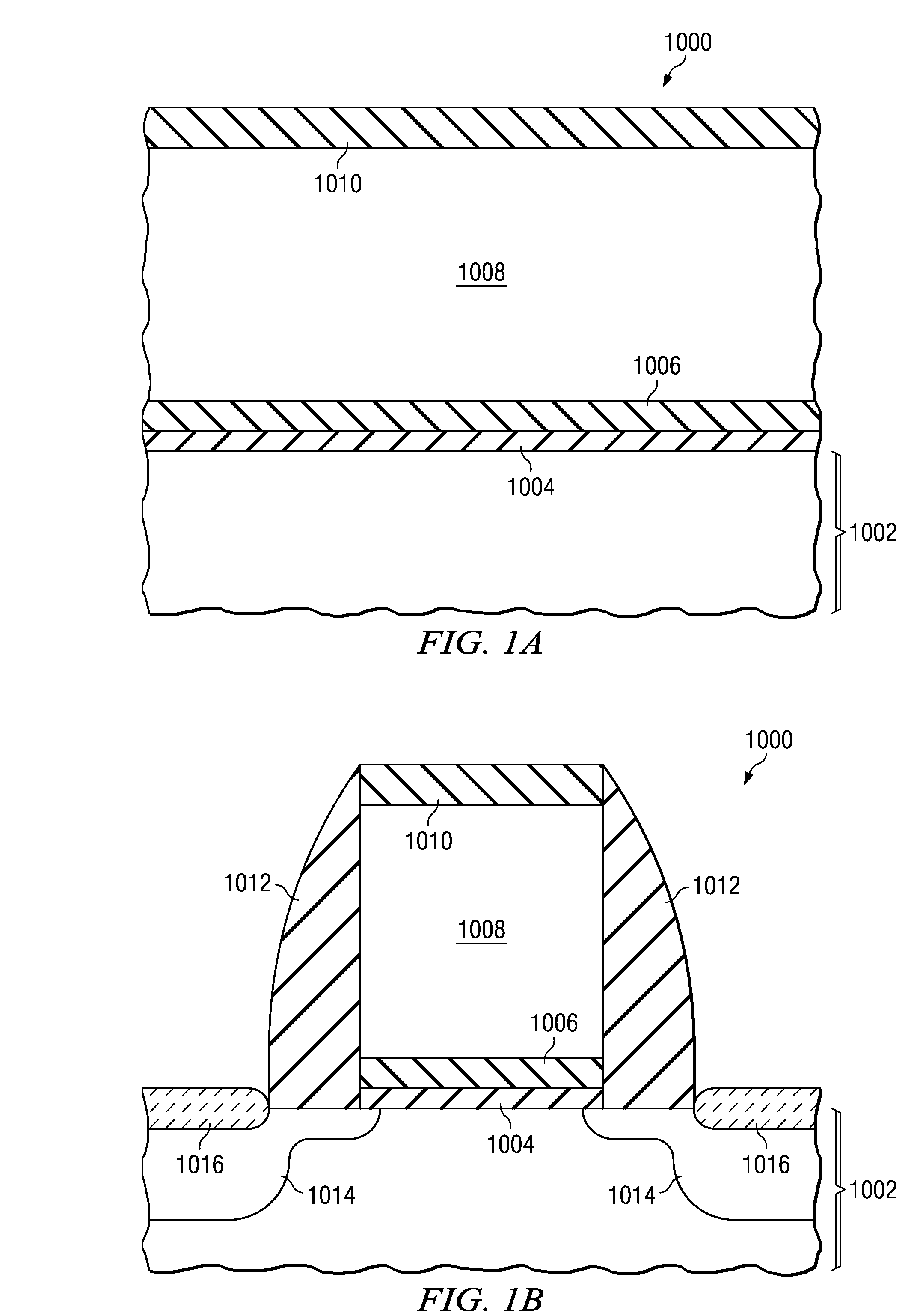

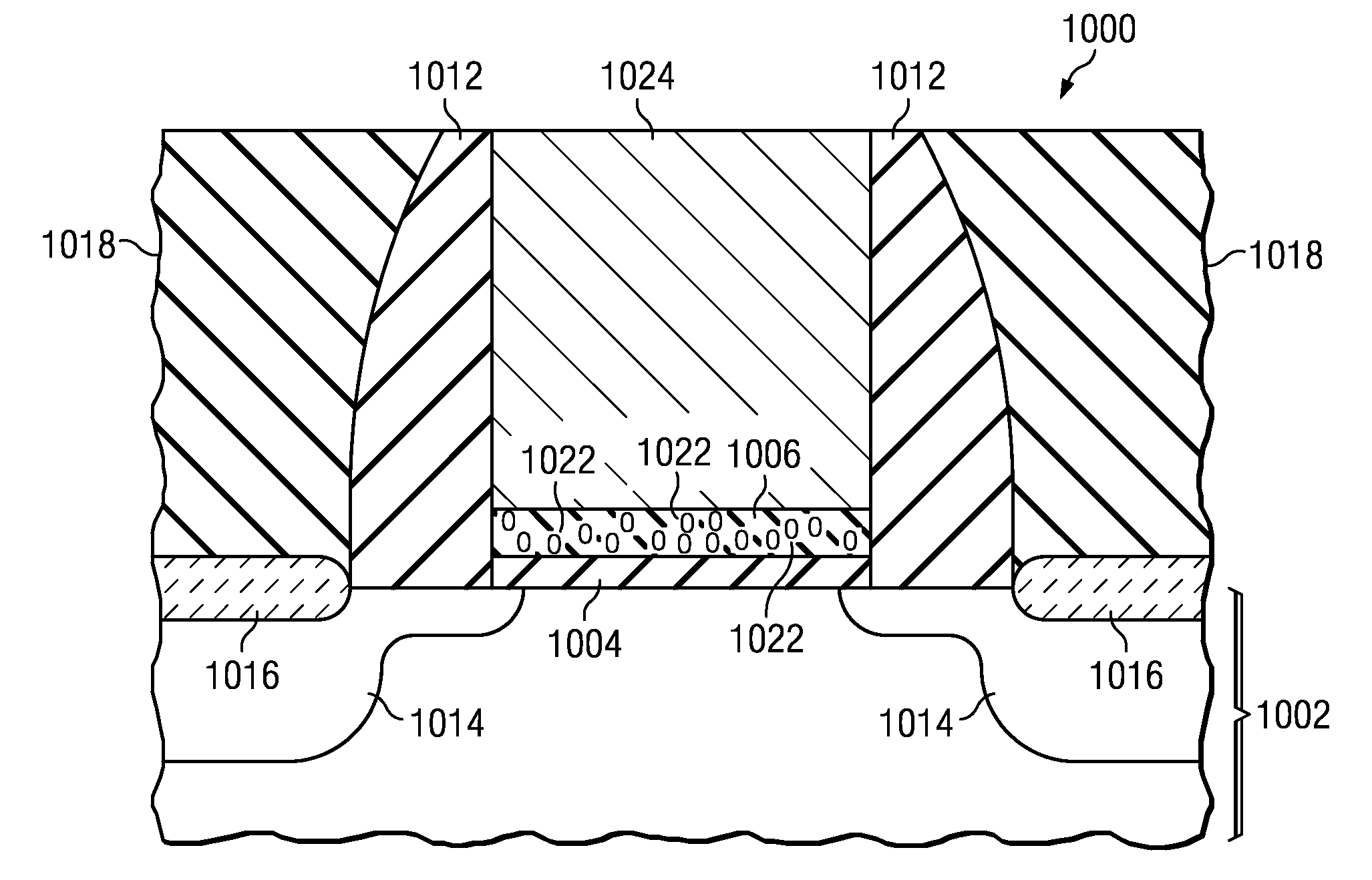

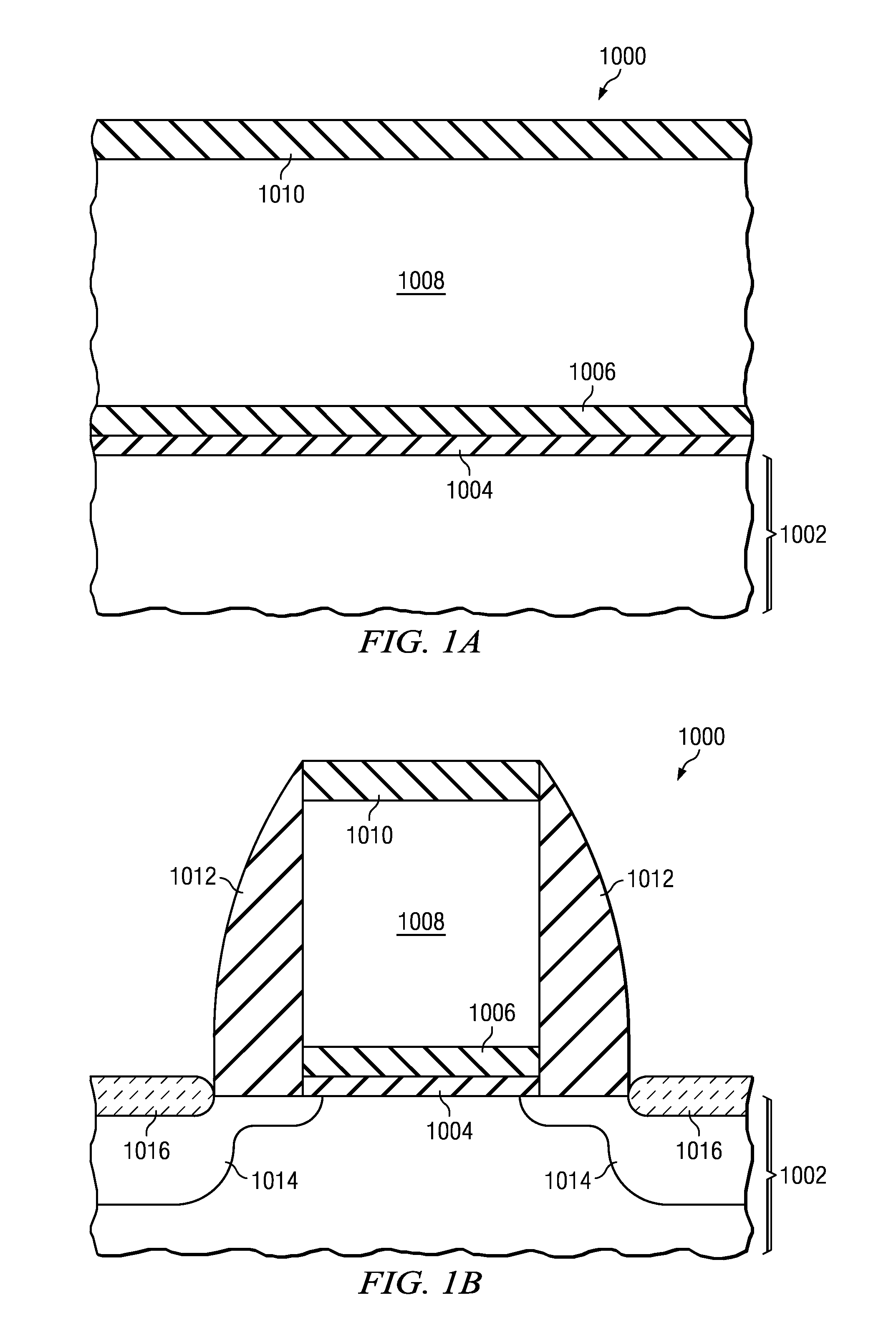

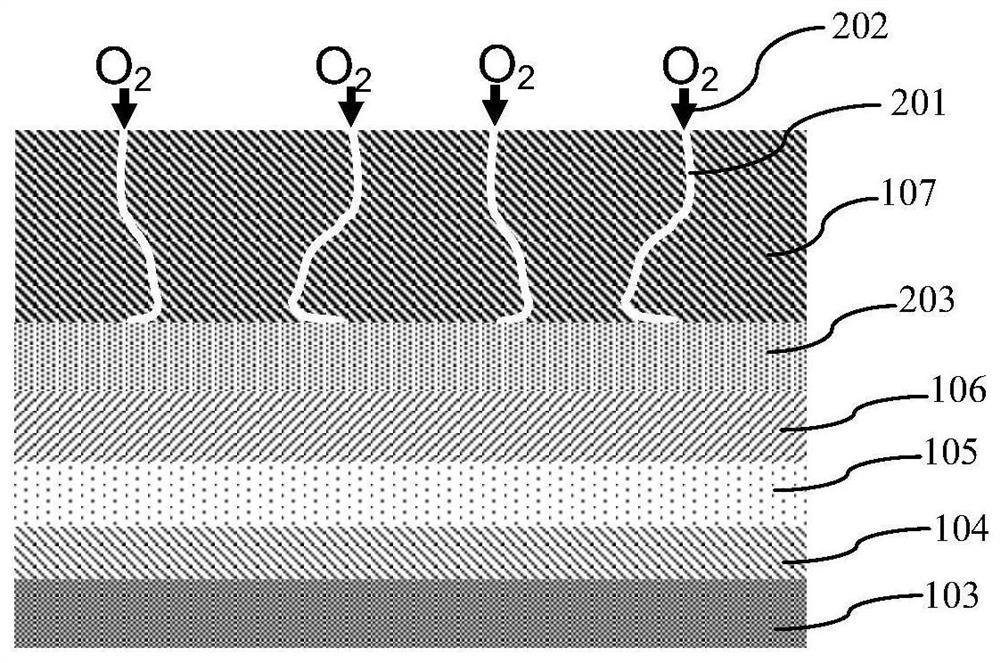

Structure and method for metal gate stack oxygen concentration control using an oxygen diffusion barrier layer and a sacrificial oxygen gettering layer

ActiveUS20100127336A1Increase their effective work functionTransistorSemiconductor/solid-state device manufacturingWork functionDiffusion barrier

A process is disclosed of forming metal replacement gates for NMOS and PMOS transistors with oxygen in the PMOS metal gates and metal atom enrichment in the NMOS gates such that the PMOS gates have effective work functions above 4.85 eV and the NMOS gates have effective work functions below 4.25 eV. Metal work function layers in both the NMOS and PMOS gates are oxidized to increase their effective work functions to the desired PMOS range. An oxygen diffusion blocking layer is formed over the PMOS gate and an oxygen getter is formed over the NMOS gates. A getter anneal extracts the oxygen from the NMOS work function layers and adds metal atom enrichment to the NMOS work function layers, reducing their effective work functions to the desired NMOS range. Processes and materials for the metal work function layers, the oxidation process and oxygen gettering are disclosed.

Owner:TEXAS INSTR INC

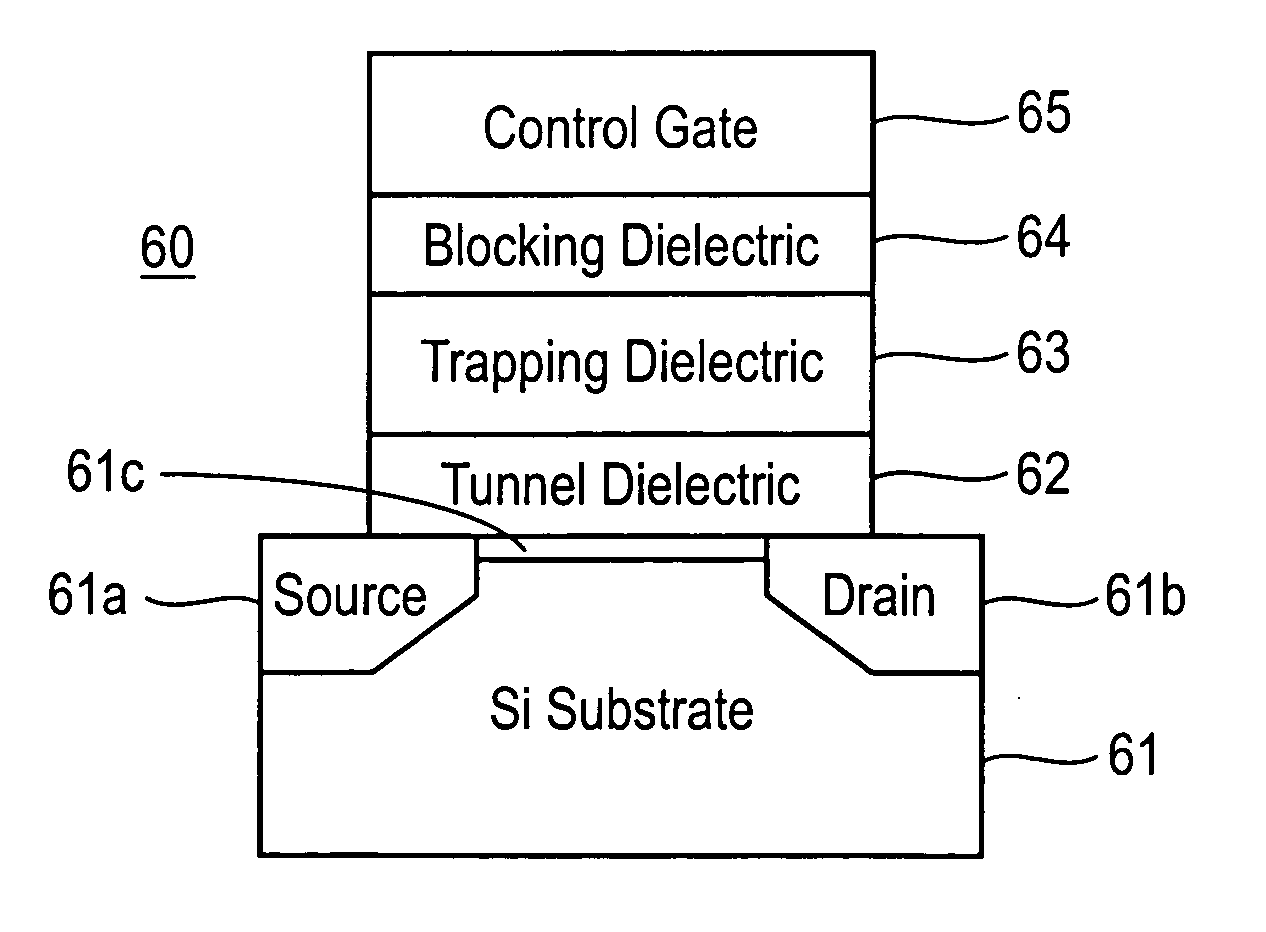

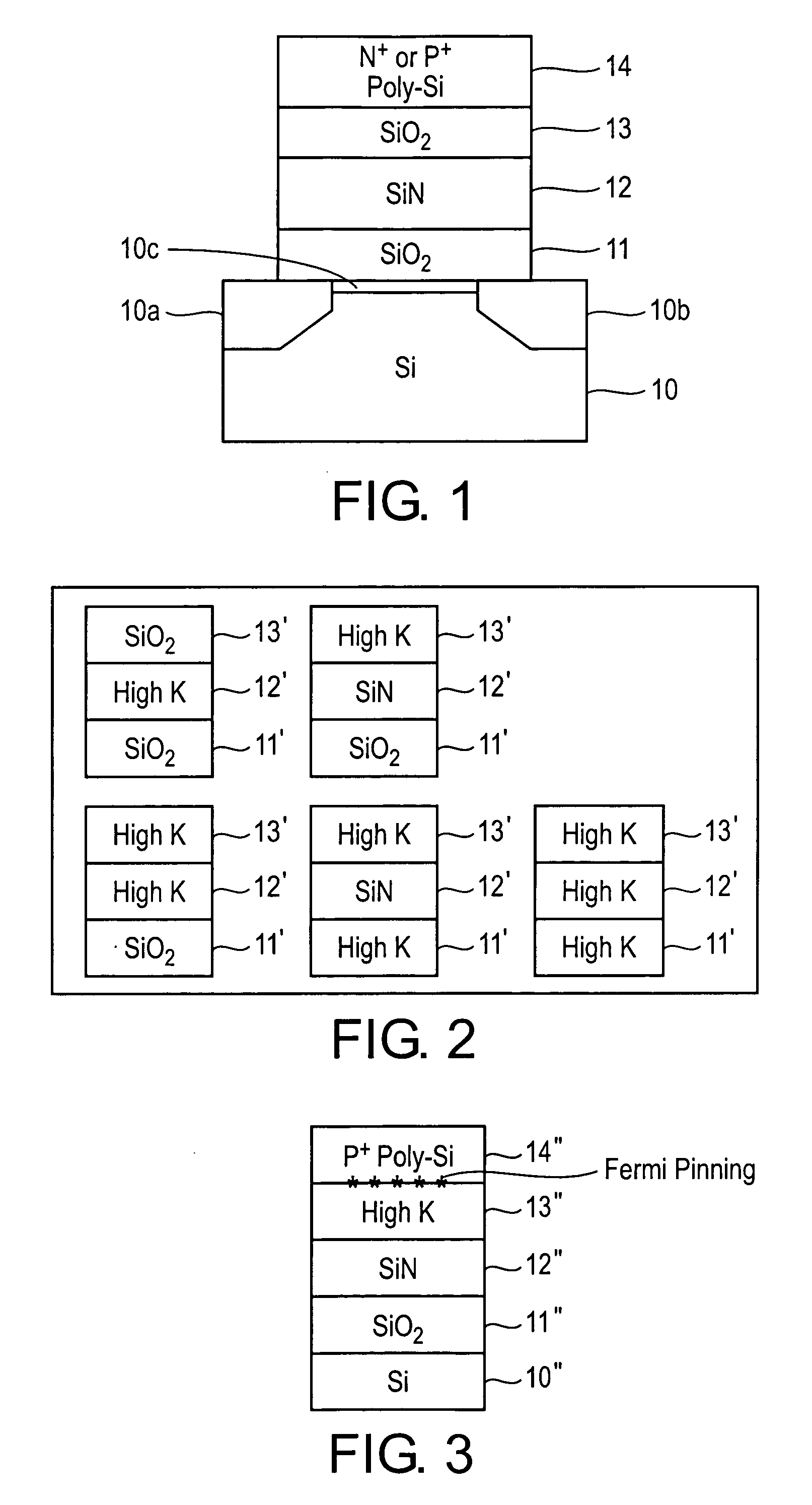

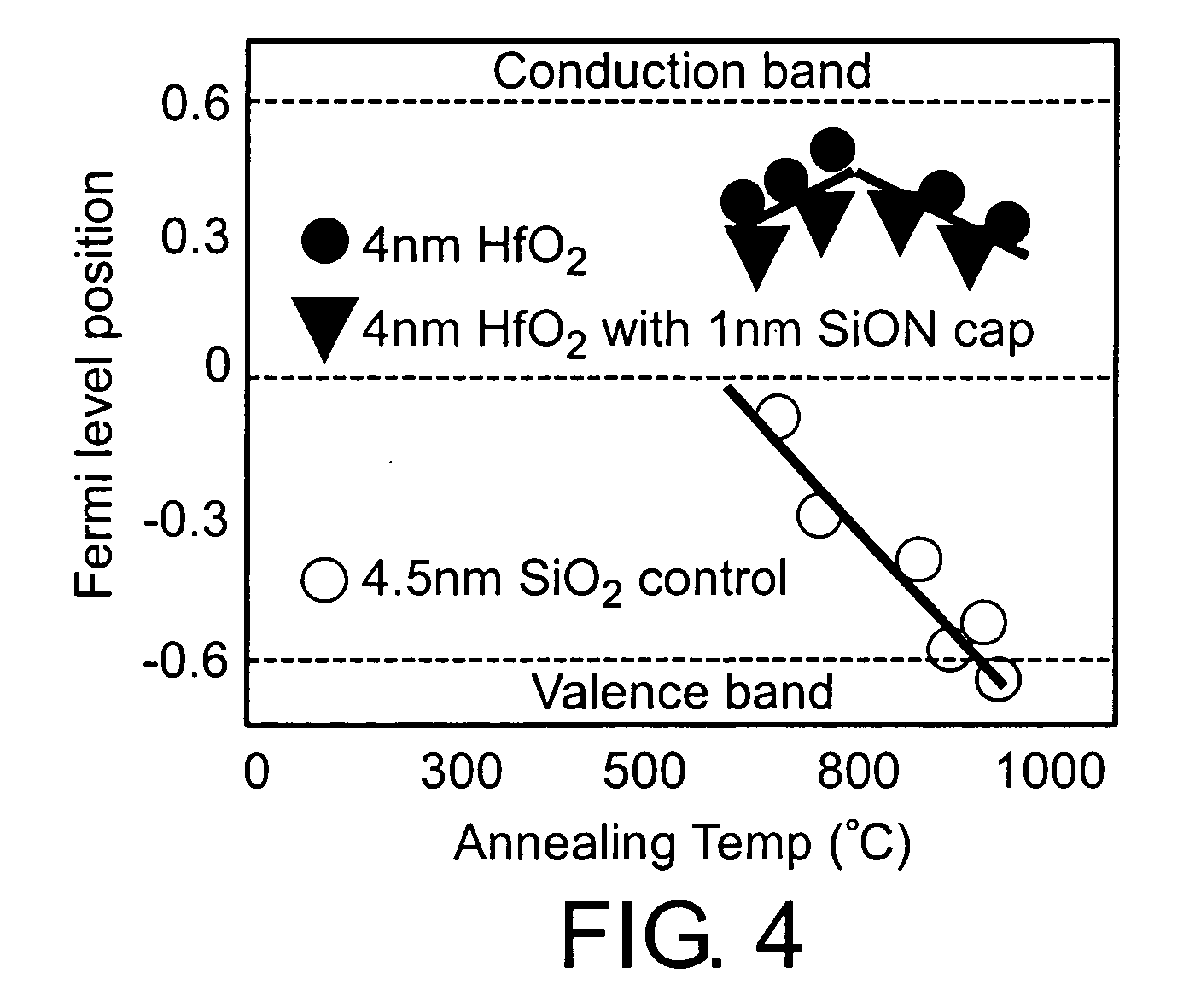

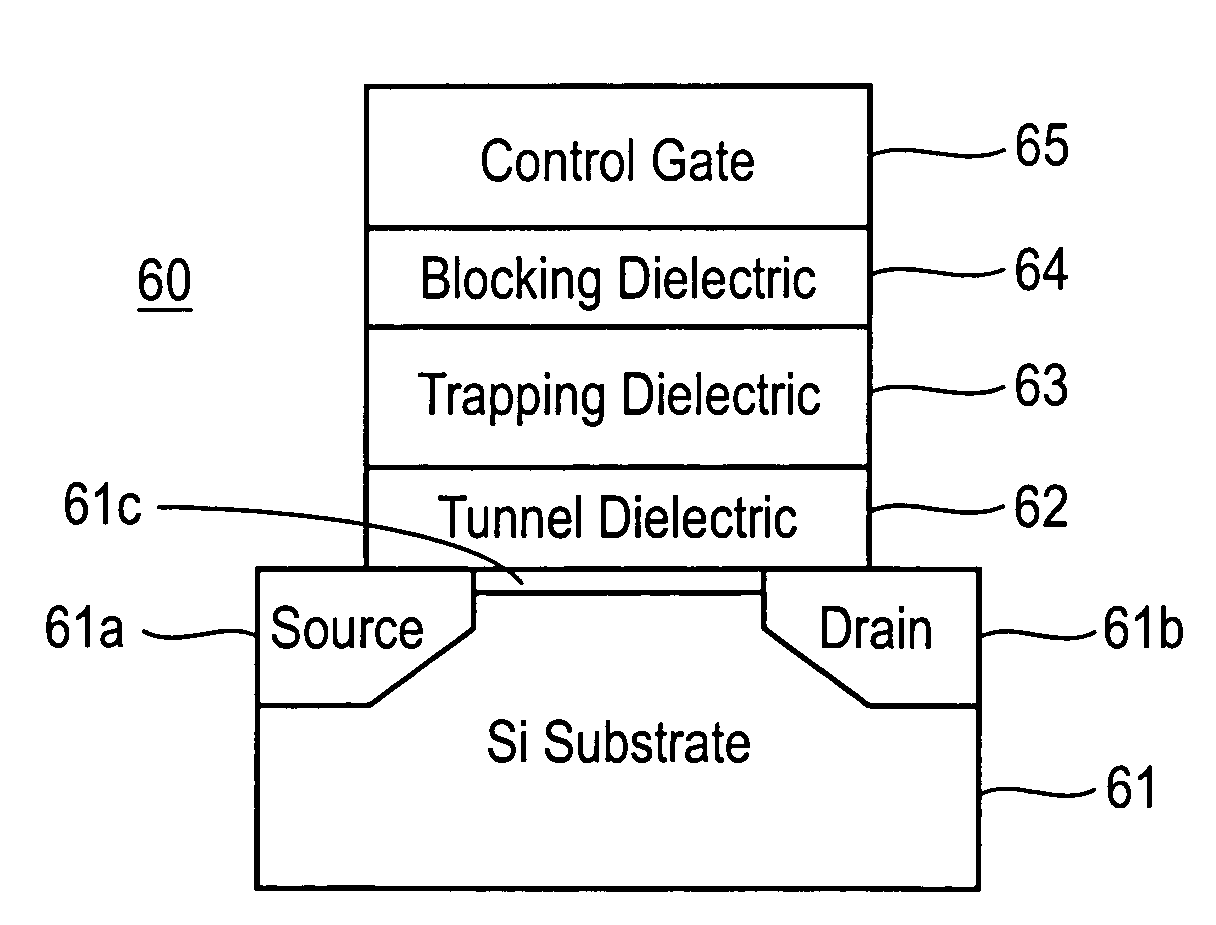

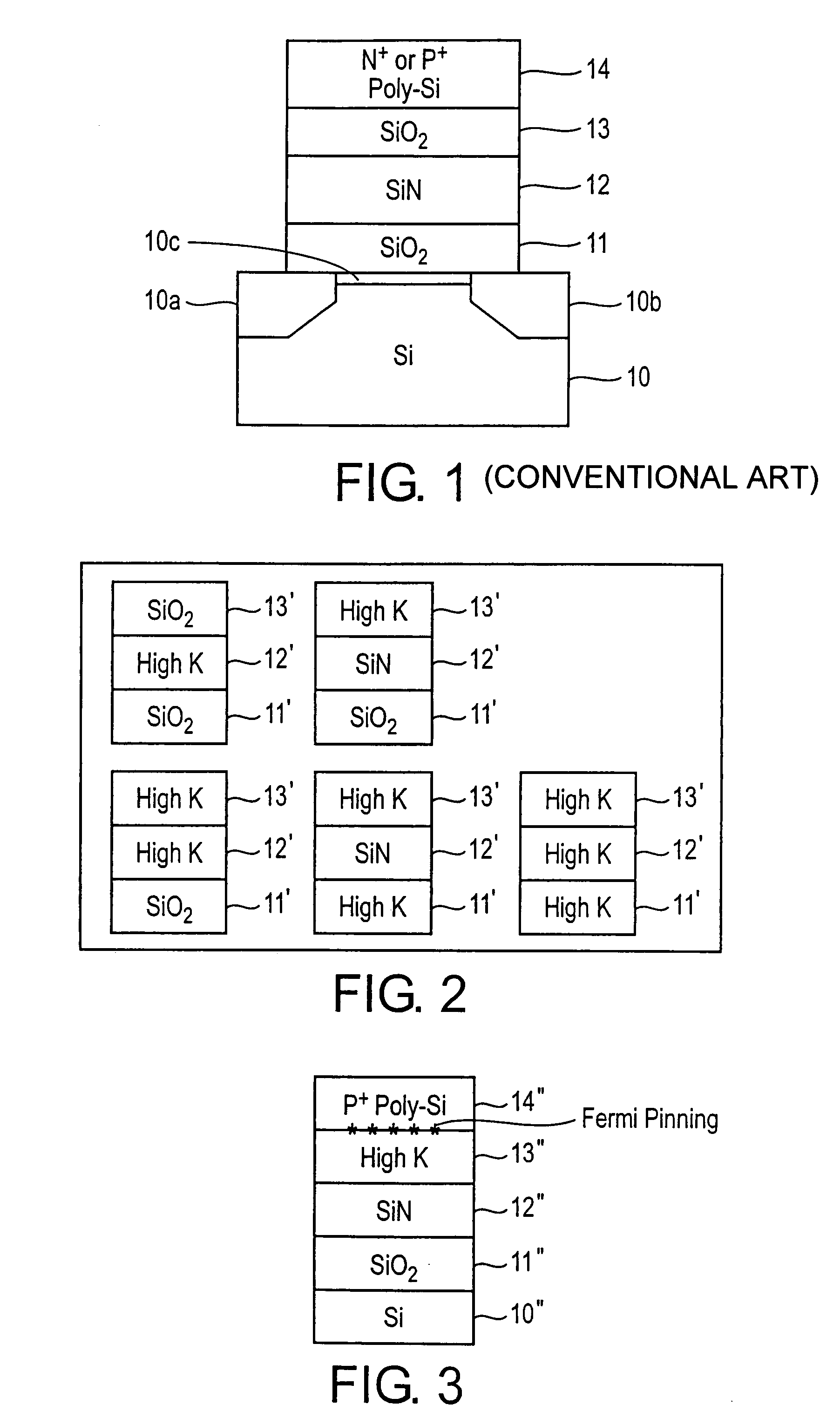

Non-volatile semiconductor memory device with alternative metal gate material

A non-volatile semiconductor memory device comprises a substrate including a source region, a drain region and a channel region provided between the source region and the drain region with a gate stack located above the channel region with a metal gate located above the gate stack. The metal gate is comprised of a metal having a specific metal work function relative to a composition of a layer of the gate stack that causes electrons to travel through the entire thickness of the blocking layer via direct tunneling. The gate stack preferably comprises a multiple layer stack selected from a group of multiple layer stacks consisting of: ONO, ONH, OHH, OHO, HHH, or HNH, where O is an oxide material, N is SiN, and H is a high κ material.

Owner:SAMSUNG ELECTRONICS CO LTD

Non-volatile semiconductor memory device with alternative metal gate material

Owner:SAMSUNG ELECTRONICS CO LTD

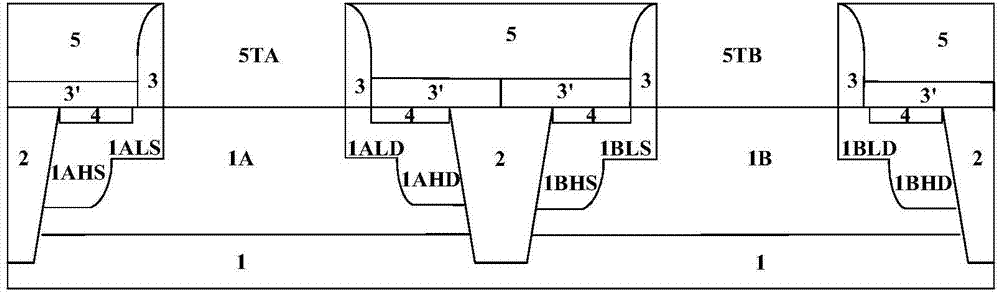

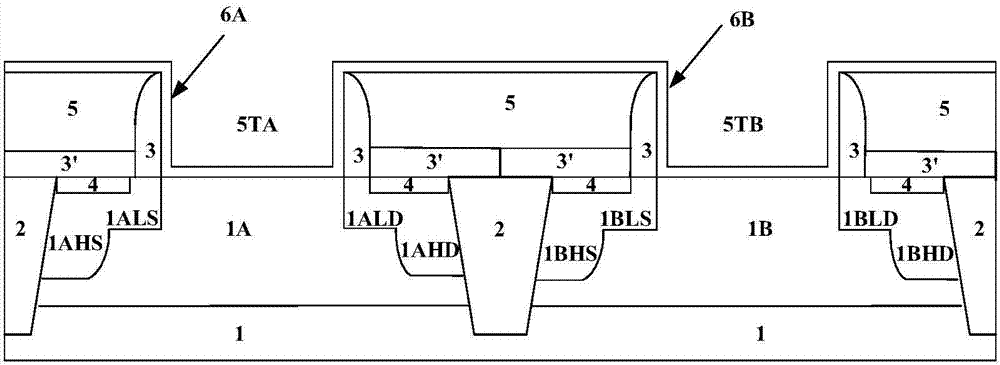

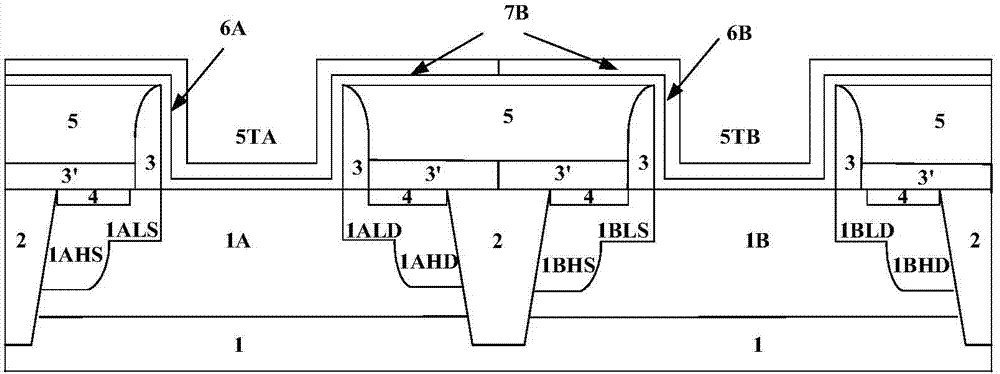

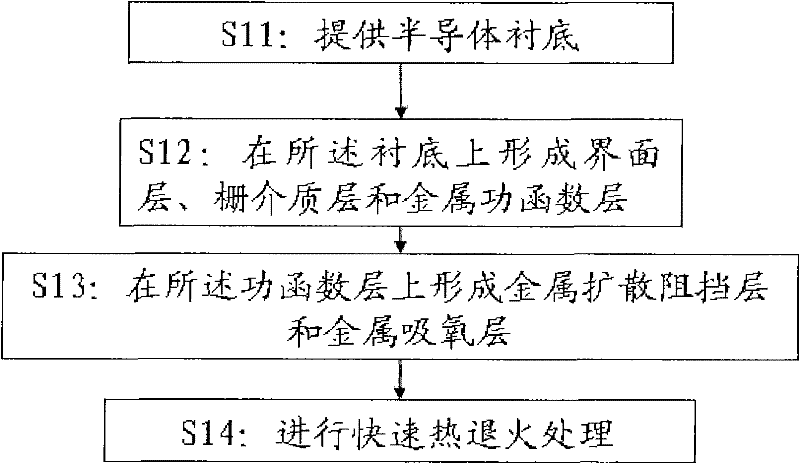

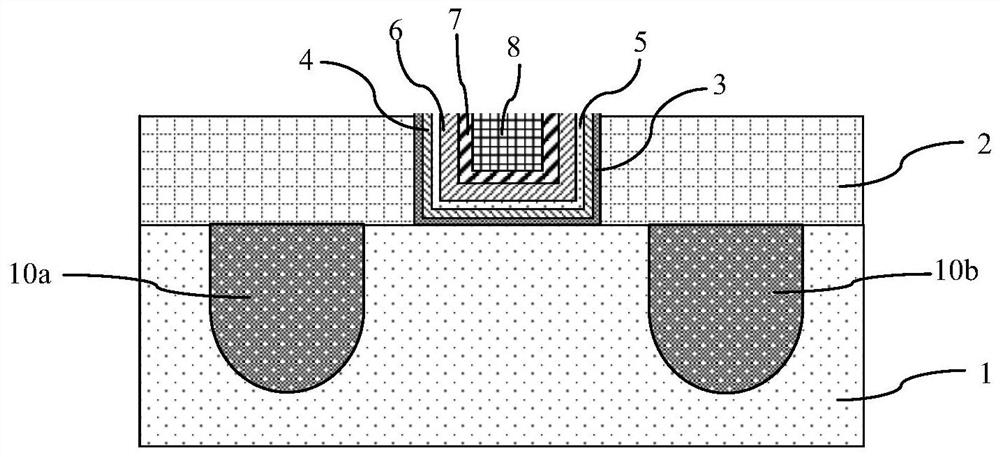

Semiconductor device manufacturing method

InactiveCN104766823AReduce thicknessEasy to integrateSemiconductor/solid-state device manufacturingCMOSGate dielectric

The invention discloses a semiconductor device manufacturing method, which comprises steps: multiple first gate grooves and multiple second gate grooves are formed in a substrate; gate dielectric layers are formed in the multiple first gate grooves and the multiple second gate grooves; a second metal work function adjustment layer is formed on each gate dielectric layer; thicknesses of the second metal work function adjustment layers in the multiple first gate grooves are selectively adjusted; a first metal work function adjustment layer is formed on each second metal work function adjustment layer; a diffusion barrier layer is formed on the first metal work function adjustment layer; and a gate metal layer is formed on the diffusion barrier layer. According to the semiconductor device manufacturing method of the invention, through selectively depositing / etching the multiple metal work function layers on different device areas, the CMOS integrated technology is simplified, multi-threshold voltage regulation and control can be realized, and performance of the device is further improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

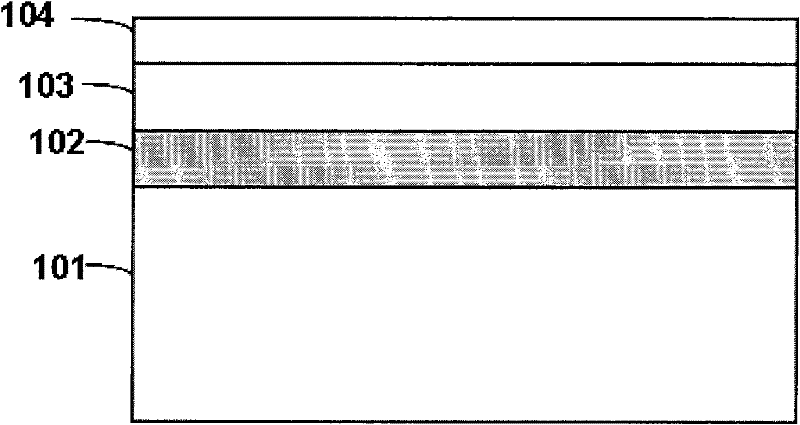

A method of manufacturing a semiconductor device

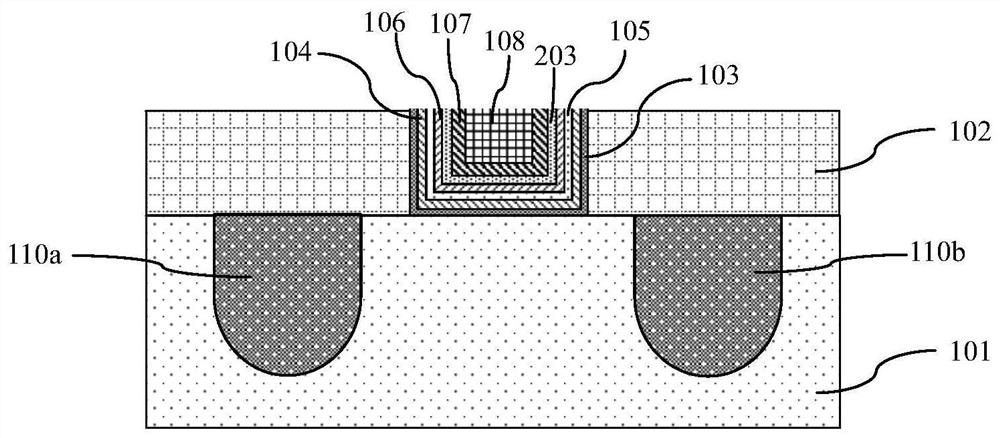

ActiveCN102299061AAvoid enteringIncreasing the thicknessSemiconductor devicesEquivalent oxide thicknessGate dielectric

The invention relates to the field of semiconductor manufacturing and provides a method for manufacturing a semiconductor device. The method comprises the following steps: providing a semiconductor substrate; forming an interface layer, a gate dielectric layer and a metal work function layer on the substrate; forming a diffusion barrier layer on the metal work function layer; forming a metal oxygen absorbing layer on the diffusion barrier layer; and carrying out thermal annealing treatment on the device so as to ensure the metal oxygen absorbing layer to absorb the oxygen in the interface layer to reduce the thickness of the interface layer and ensure the diffusion barrier layer to prevent the oxygen absorbing metals in the metal oxygen absorbing layer from being diffused into the metal work function layer. By adopting the method, the oxygen absorbing metals can be prevented from being diffused into the work function layer and / or gate dielectric layer while the thickness of the interface layer is reduced, thus reducing the equivalent oxide thickness under the premise of not affecting the threshold voltage of the device.

Owner:锐立平芯微电子(广州)有限责任公司

Structure and method for metal gate stack oxygen concentration control using an oxygen diffusion barrier layer and a sacrificial oxygen gettering layer

A process is disclosed of forming metal replacement gates for NMOS and PMOS transistors with oxygen in the PMOS metal gates and metal atom enrichment in the NMOS gates such that the PMOS gates have effective work functions above 4.85 eV and the NMOS gates have effective work functions below 4.25 eV. Metal work function layers in both the NMOS and PMOS gates are oxidized to increase their effective work functions to the desired PMOS range. An oxygen diffusion blocking layer is formed over the PMOS gate and an oxygen getter is formed over the NMOS gates. A getter anneal extracts the oxygen from the NMOS work function layers and adds metal atom enrichment to the NMOS work function layers, reducing their effective work functions to the desired NMOS range. Processes and materials for the metal work function layers, the oxidation process and oxygen gettering are disclosed.

Owner:TEXAS INSTR INC

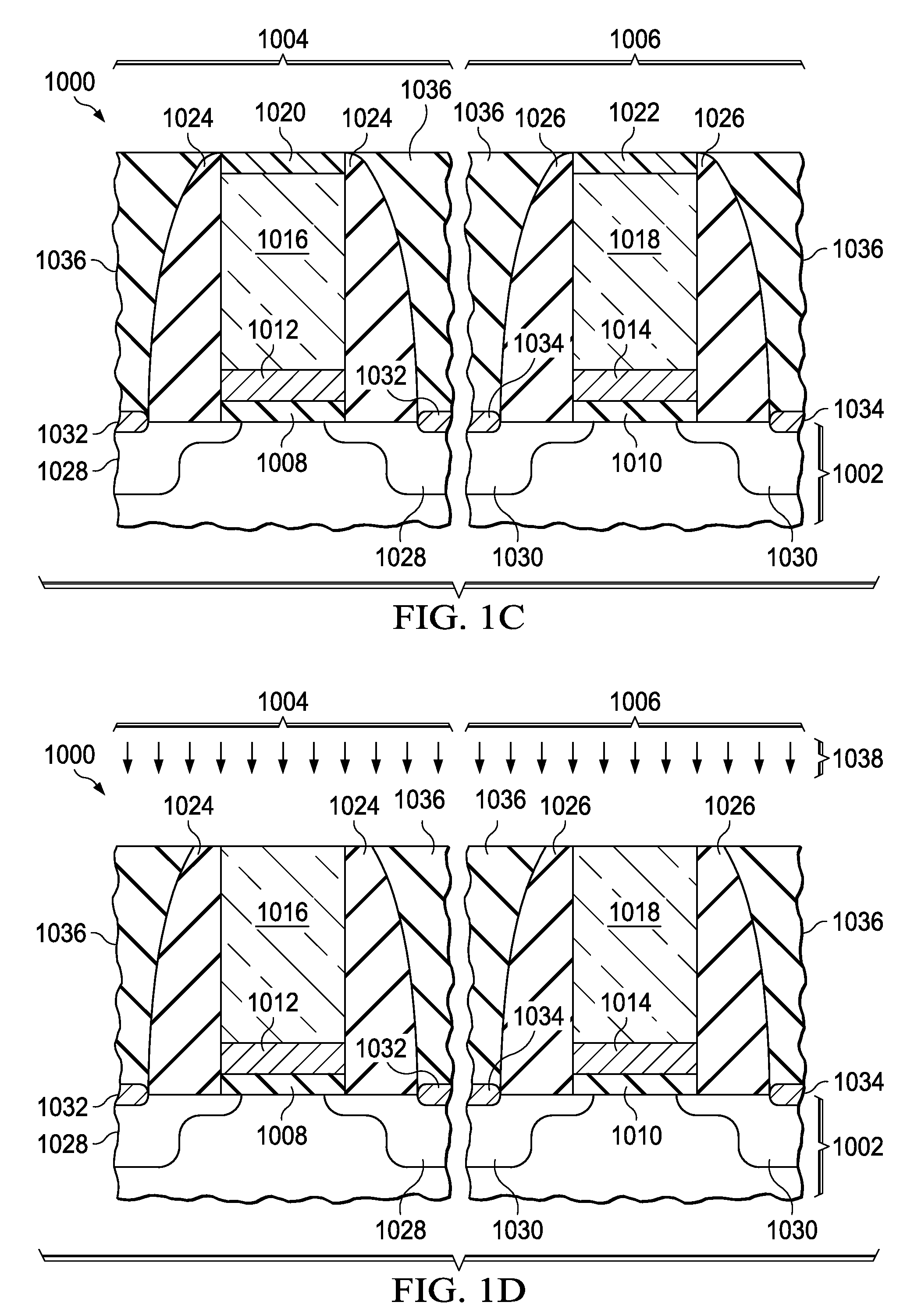

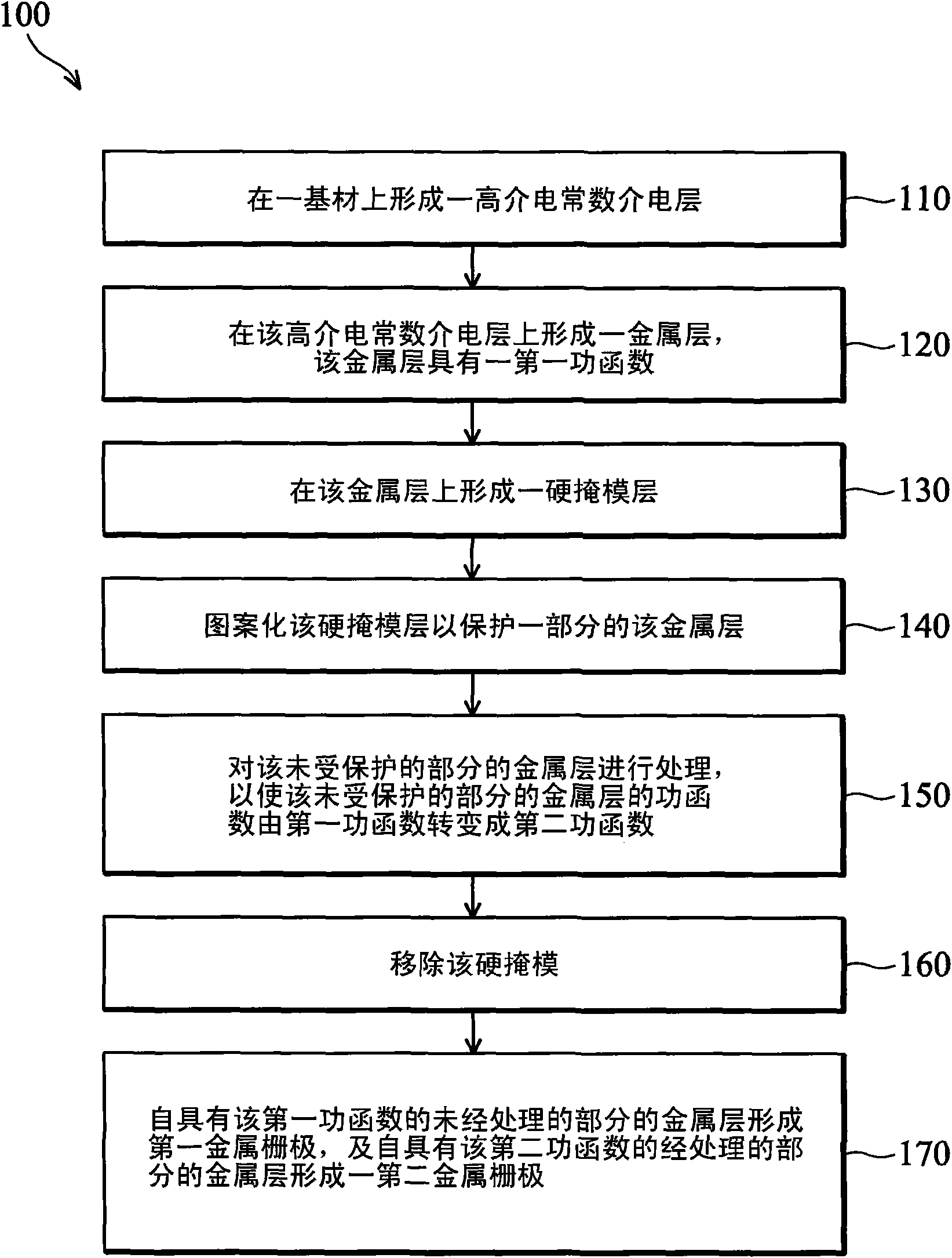

Semiconductor device and manufacturing method

The invention provides a manufacturing method of a semiconductor device. The method comprises the steps of forming a gate dielectric over a semiconductor substrate, forming a capping layer over or under the gate dielectric, forming a metal layer having a first work function over the capping layer, treating a portion of the metal layer such that a work function of the portion of the metal layer changes from the first work function to a second work function, and forming a first metal gate from the untreated portion of the metal layer having the first work function and forming a second metal gatefrom the treated portion of the metal layer having the second work function. The method of the invention provides a simple single metal layer with economic benefit to ensure that NMOS and PMOS devicerespectively have N type metal work function and P type metal work function, so gate patterning NMOS and PMOS devices are simple. The method can is compatible with prior CMOS technique manufacturingflow, so the semiconductor device can be easily integrated with the prior manufacturing processing equipment.

Owner:TAIWAN SEMICON MFG CO LTD

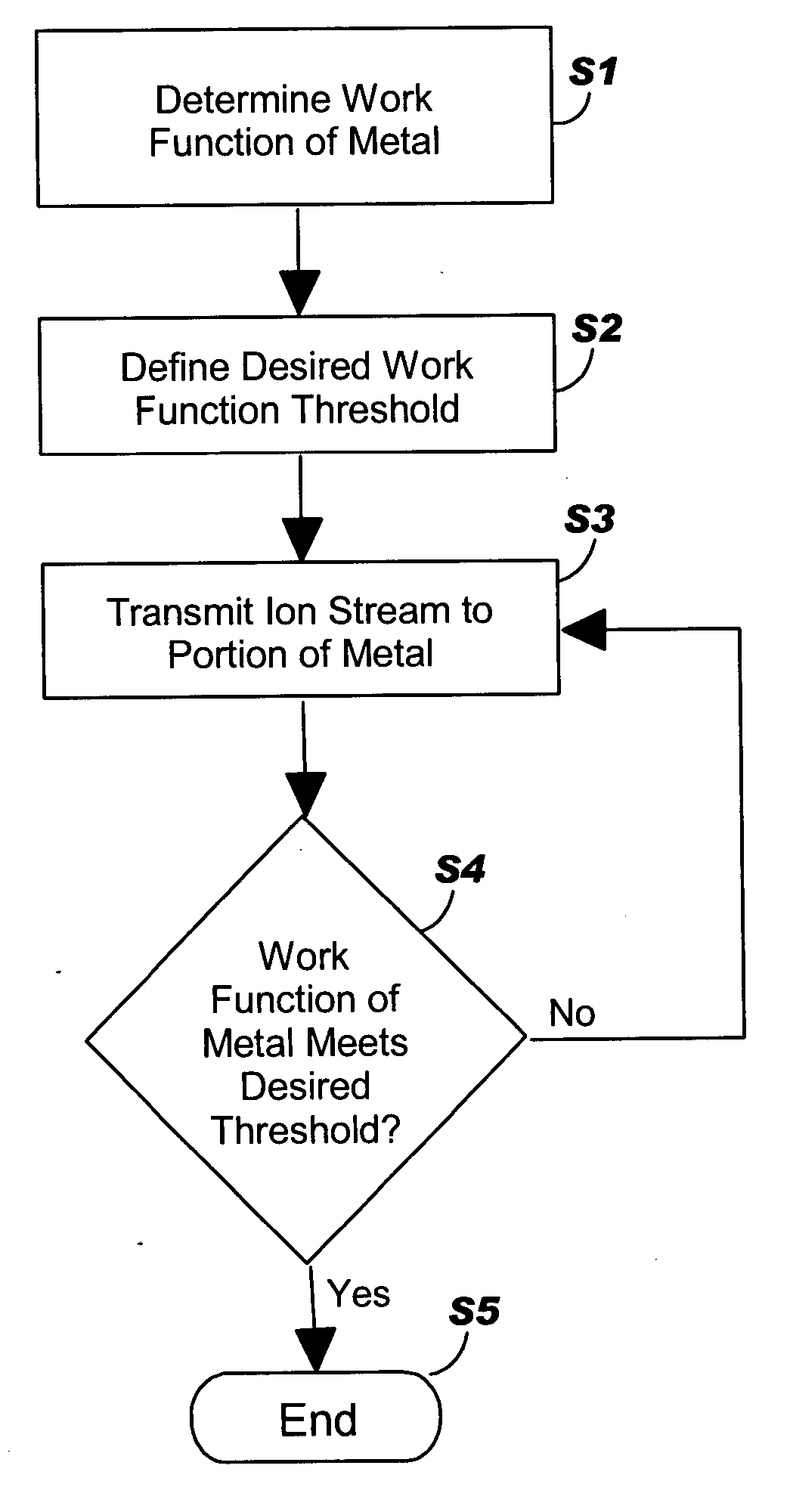

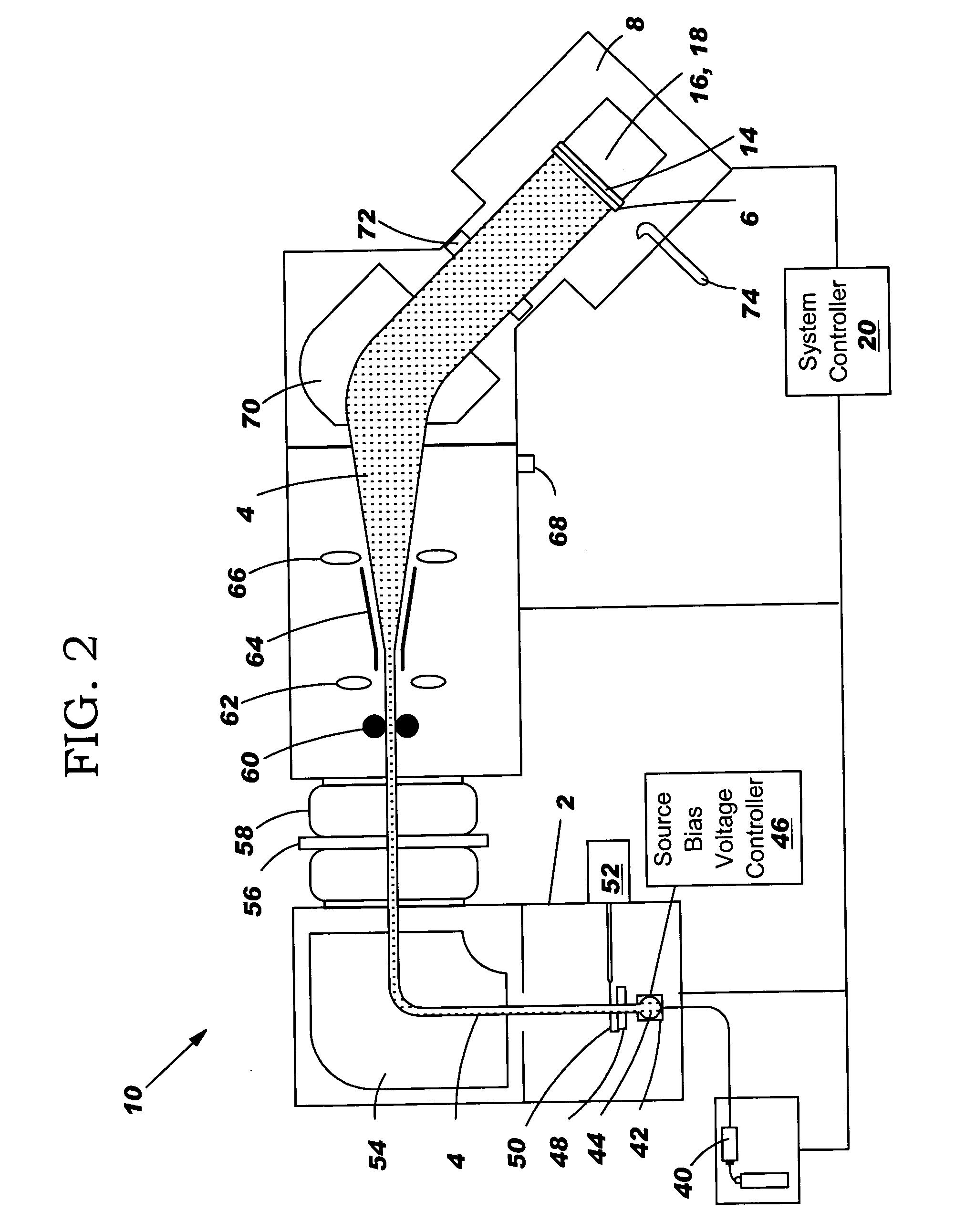

Metal work function adjustment by ion implantation

InactiveUS20070048984A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingHigh energyWork function

A system, method and program product for adjusting metal work function by ion implantation is disclosed. The invention determines the work function of the metal and determines a desired work function threshold for the metal. The desired work function threshold may be a range and is usually based on the work function of the substrate. An ion implanter system is then used to implant ions to at least a portion of the metal. The ion implantation is usually a high-energy ion stream including a material that is calculated to modify the work function of the metal. The ion implanter system continues to transmit the ion stream into the metal until the work function of the metal meets the desired work function threshold.

Owner:VARIAN SEMICON EQUIP ASSOC INC

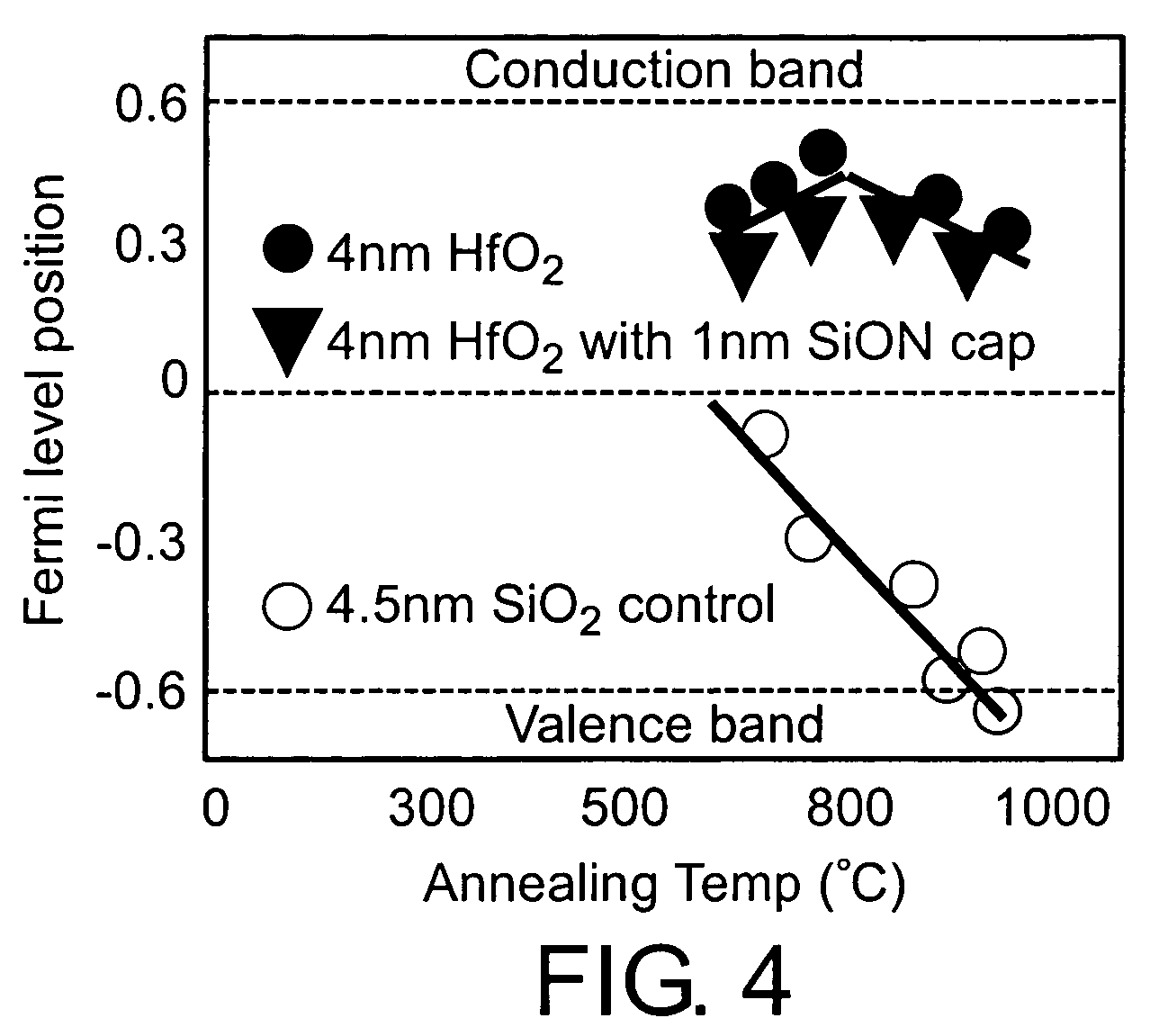

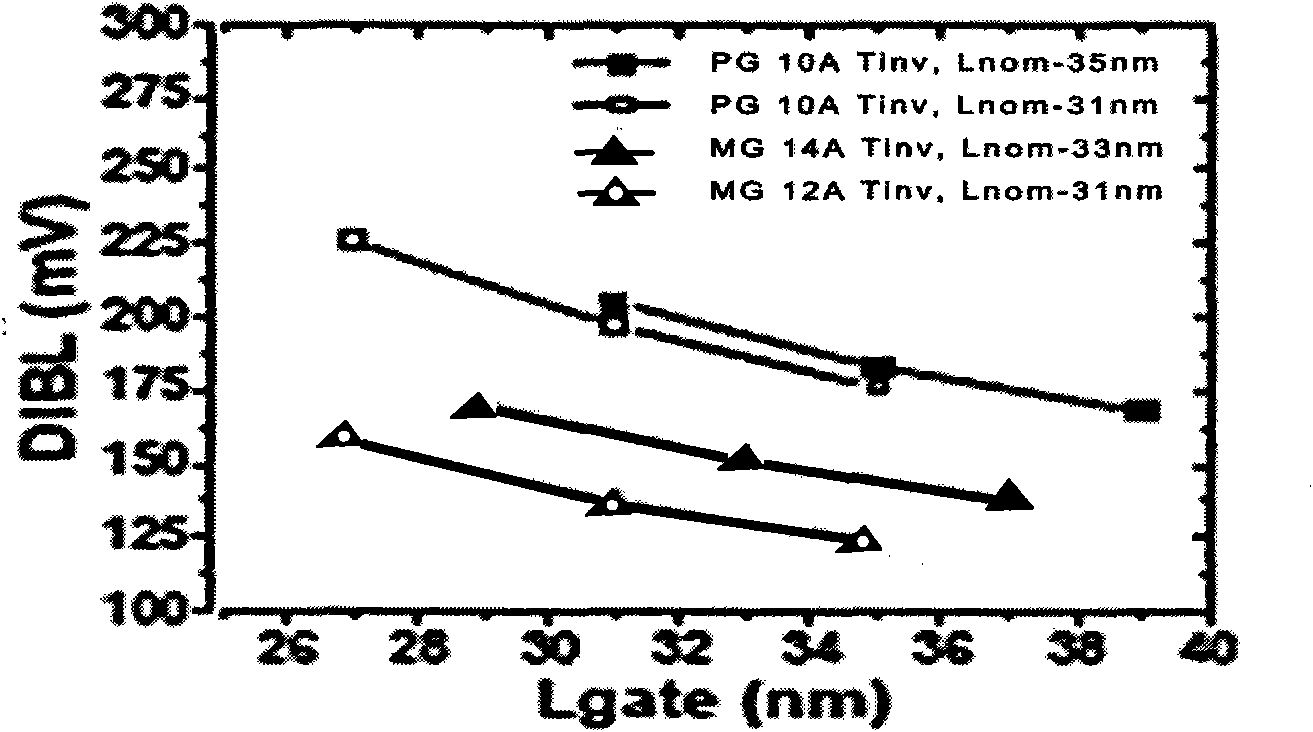

Methods to Enhance Effective Work Function of Mid-Gap Metal by Incorporating Oxygen and Hydrogen at a Low Thermal Budget

ActiveUS20110207314A1Semiconductor/solid-state device manufacturingSemiconductor devicesElectricityHydrogen

A process is disclosed of forming metal replacement gates for PMOS transistors with oxygen in the metal gates such that the PMOS gates have effective work functions above 4.85. Metal work function layers in the PMOS gates are oxidized at low temperature to increase their effective work functions to the desired PMOS range. Hydrogen may also be incorporated at an interface between the metal gates and underlying gate dielectrics. Materials for the metal work function layers and processes for the low temperature oxidation are disclosed.

Owner:TEXAS INSTR INC

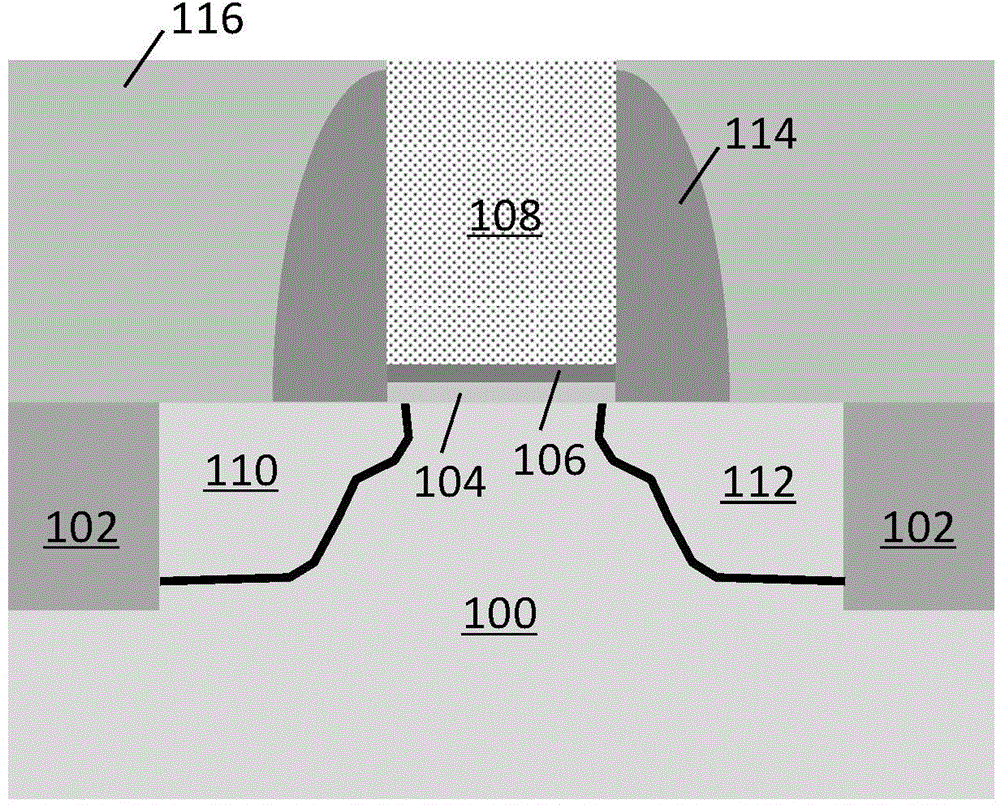

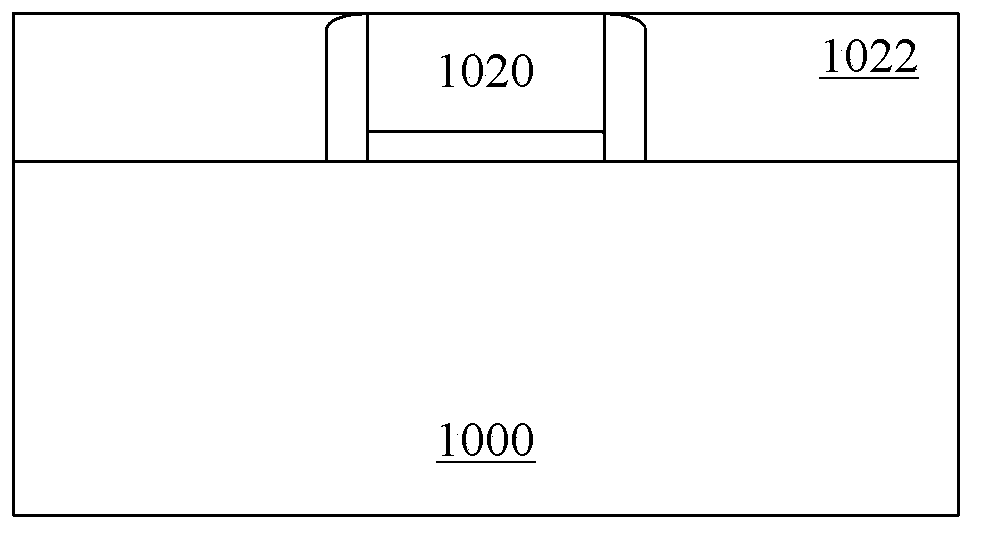

Transistor and manufacturing method thereof

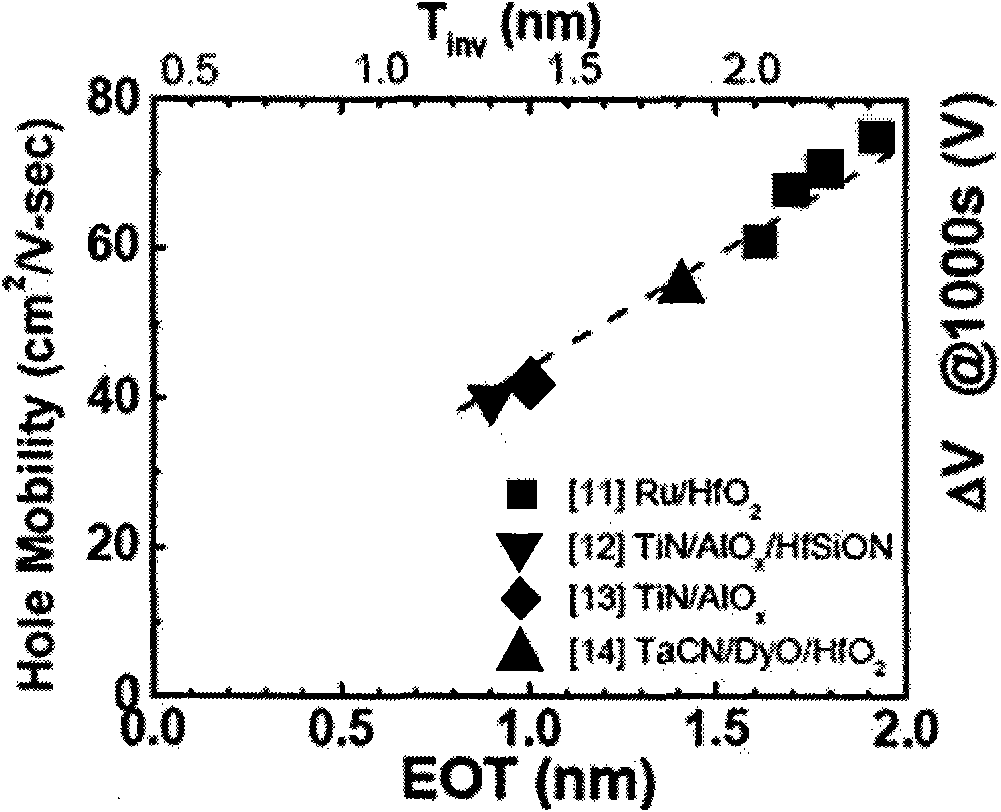

ActiveCN102117831AFeel goodEasy to understandSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierCharge carrier mobility

The invention discloses a transistor. The transistor comprises a base with a channel region, a source region, a drain region, a gate high-K dielectric layer and an interface layer, wherein the source region and the drain region are positioned at the two ends of the channel region of the base; the gate high-K dielectric layer is formed on a top layer of the base above the channel region between the source region and the drain region; the interface layer is positioned below the gate high-K dielectric layer; a first part of the interface layer is close to a source, and a second part of the interface layer is close to a drain; and an equivalent oxide layer of the first part is thicker than an equivalent oxide layer of a second layer. An asymmetric interface layer is formed by an asymmetrically substituted metal gate and is thinner on the side of the drain and is thicker on the side of the source. A short channel effect is more important on the thinner drain side, and the asymmetric interface layer contributes to controlling the short channel effect; and on the thicker source side, carrier mobility has larger influence on a device, and the asymmetric interface layer can prevent a carrier mobility rate from being reduced. In addition, the asymmetrically substituted metal gate can also form an asymmetric metal work function.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

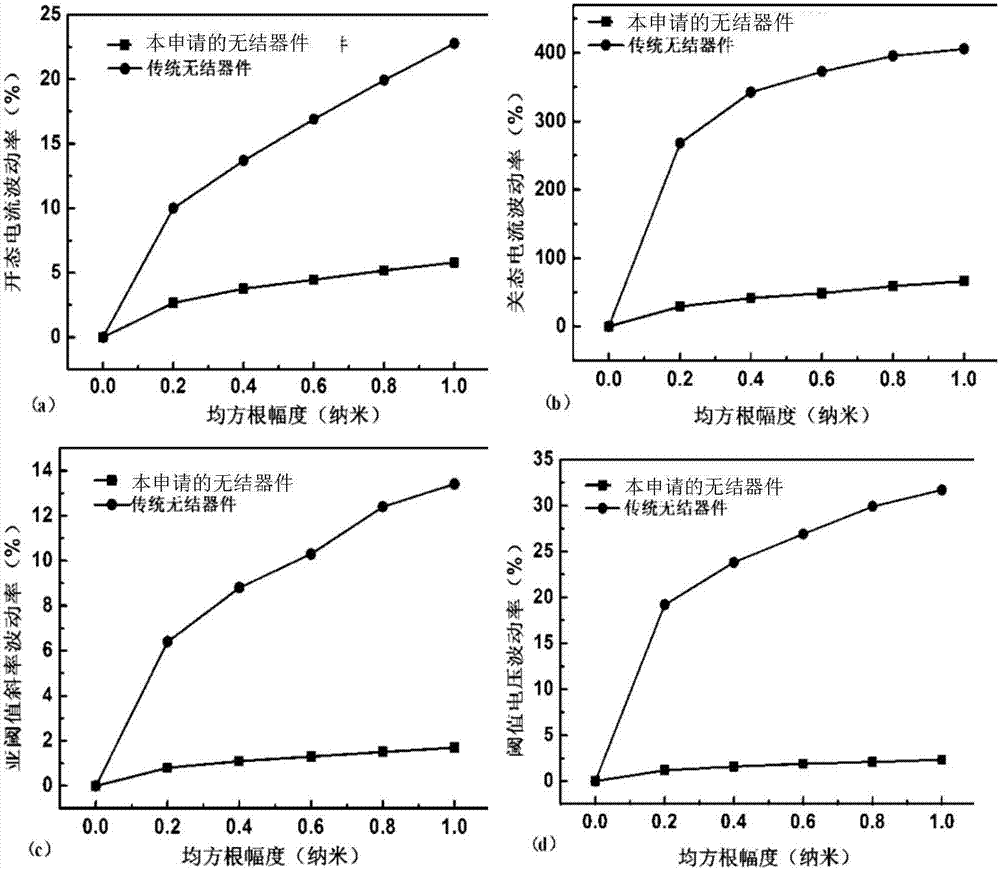

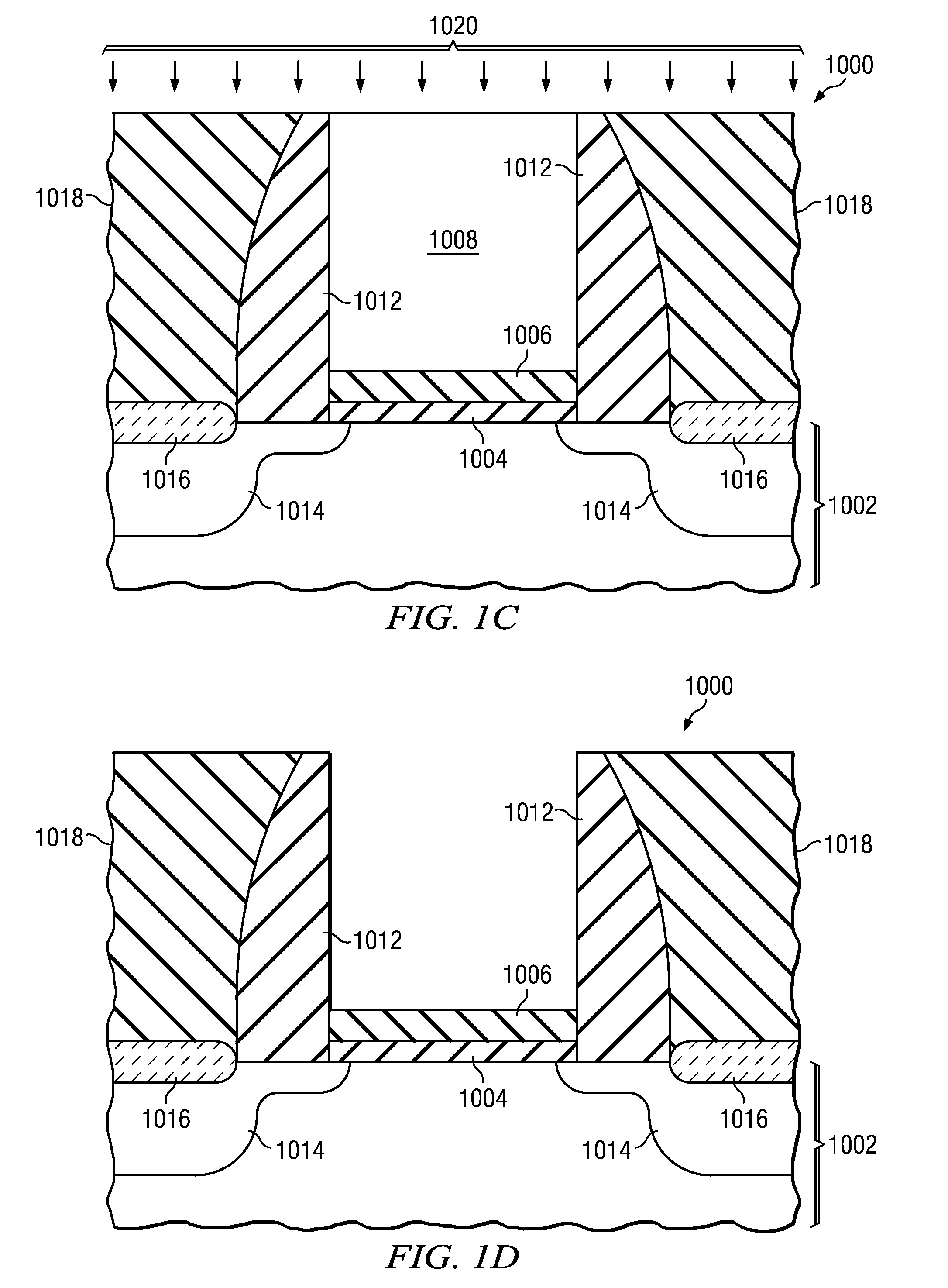

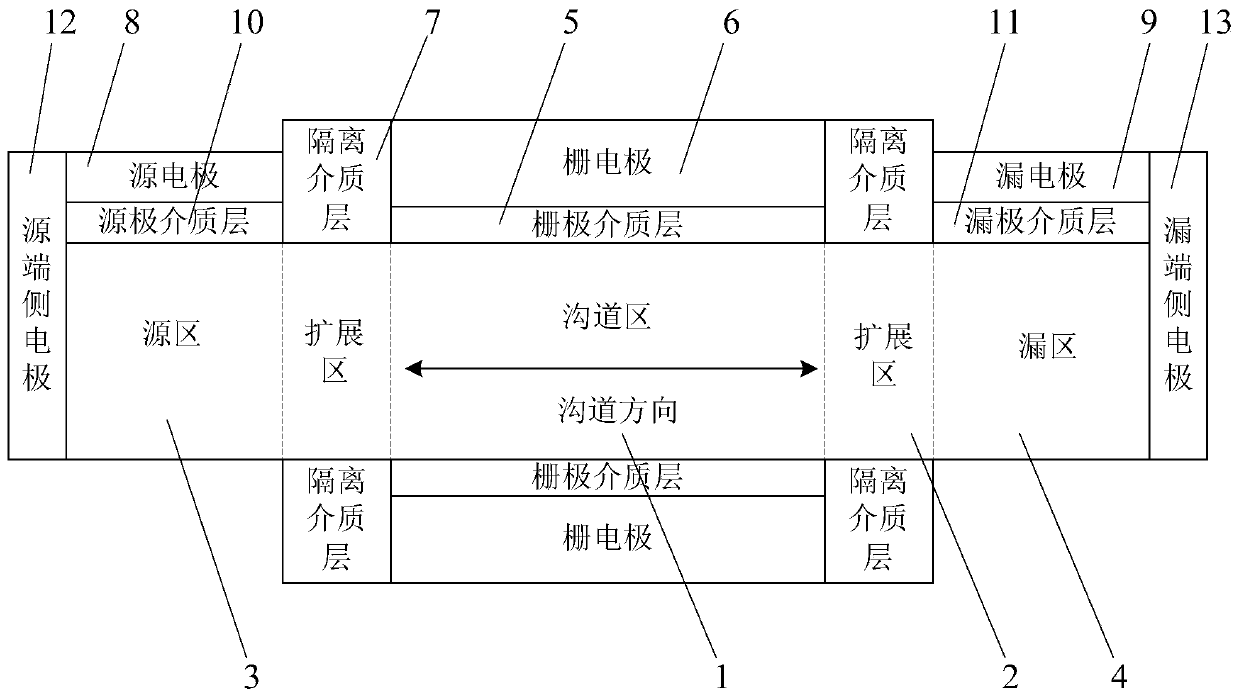

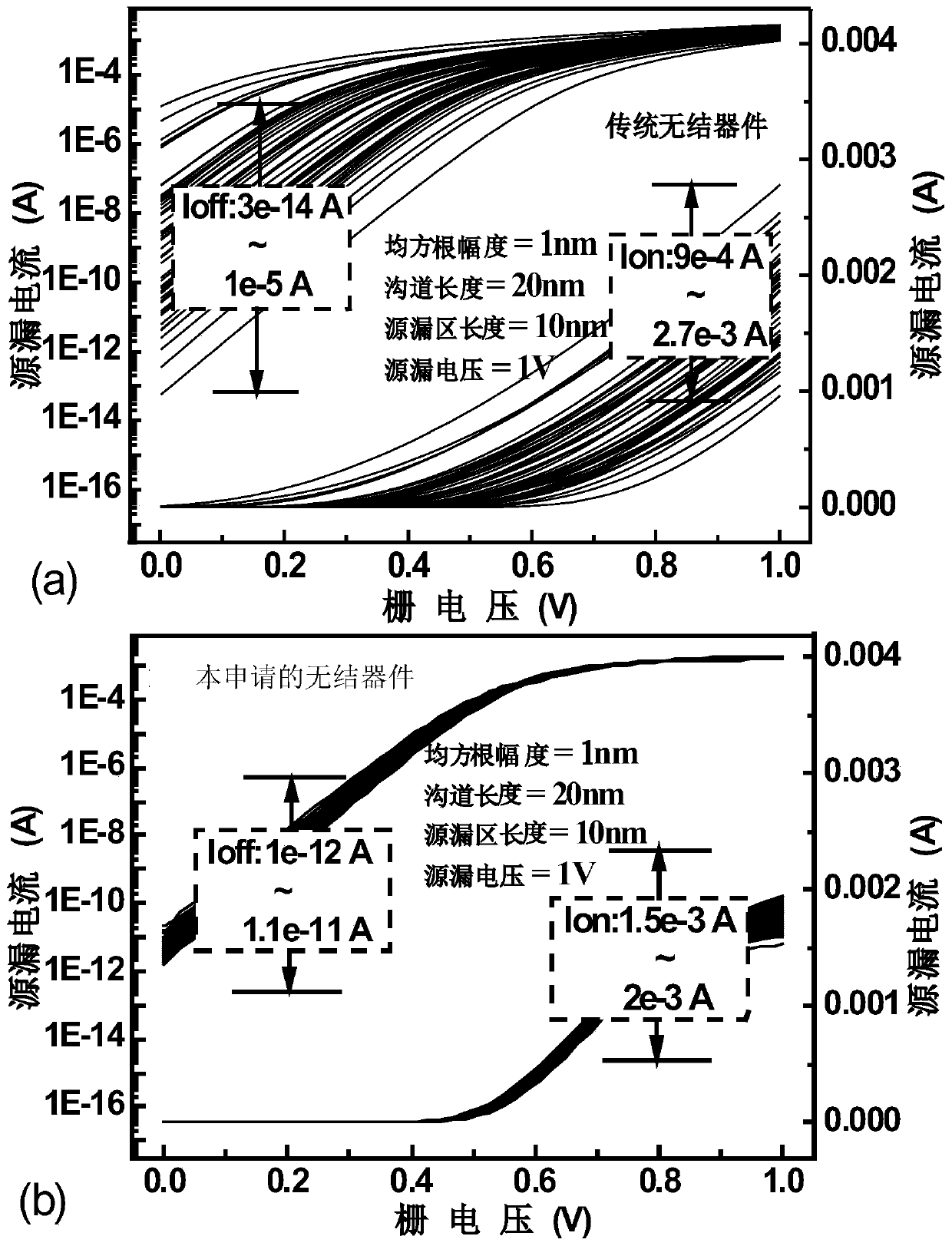

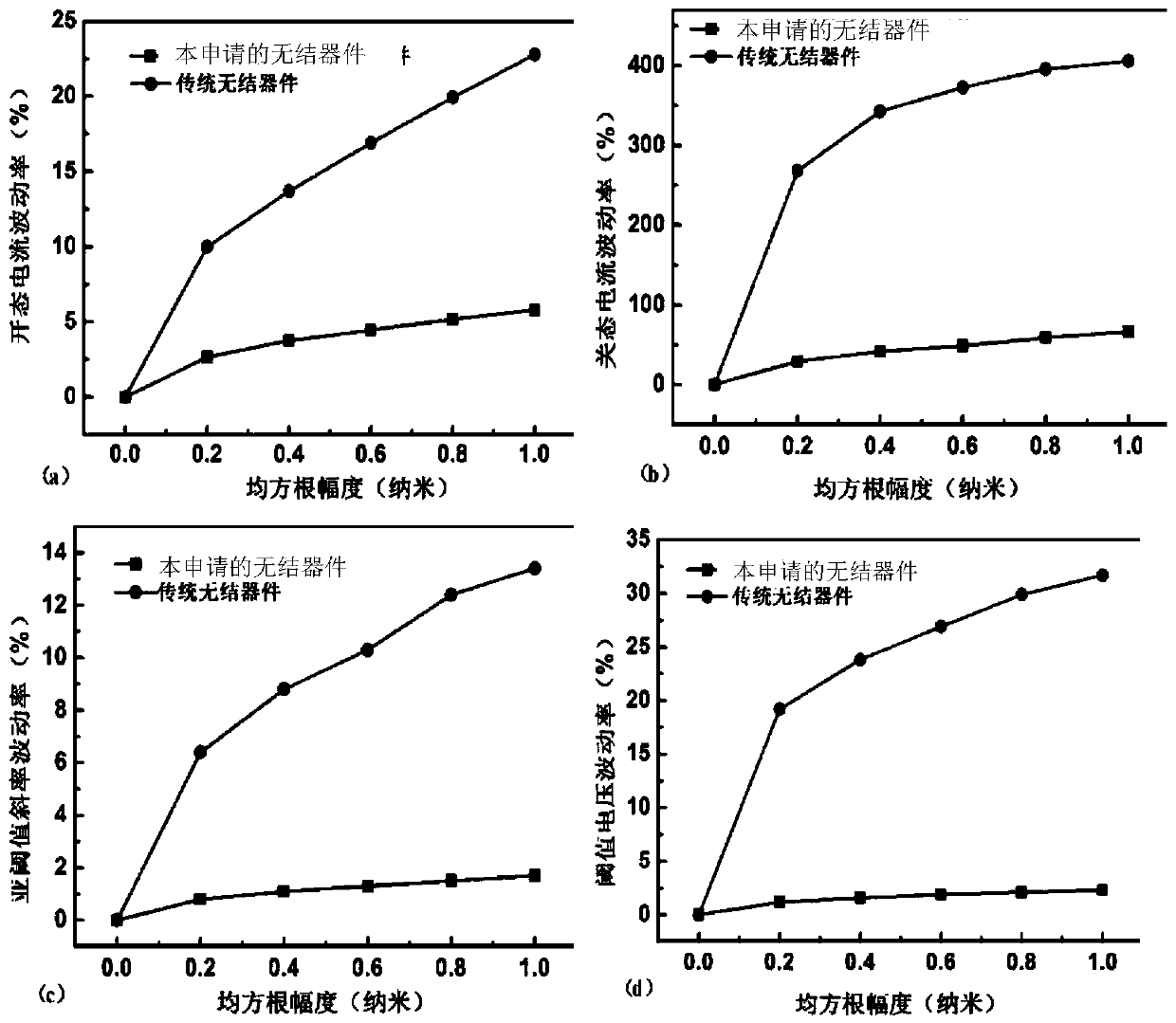

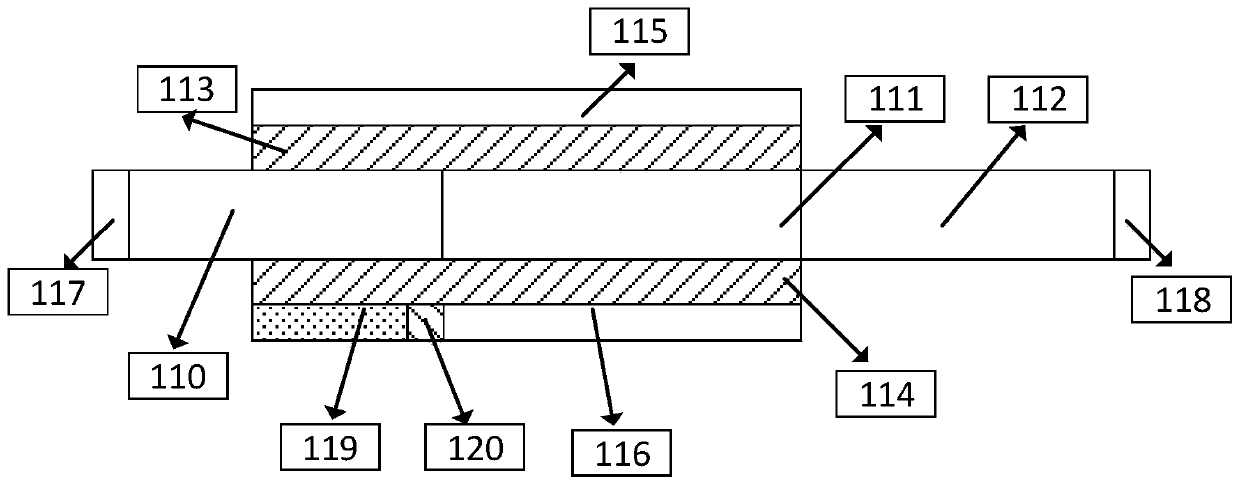

Non-junction field-effect transistor

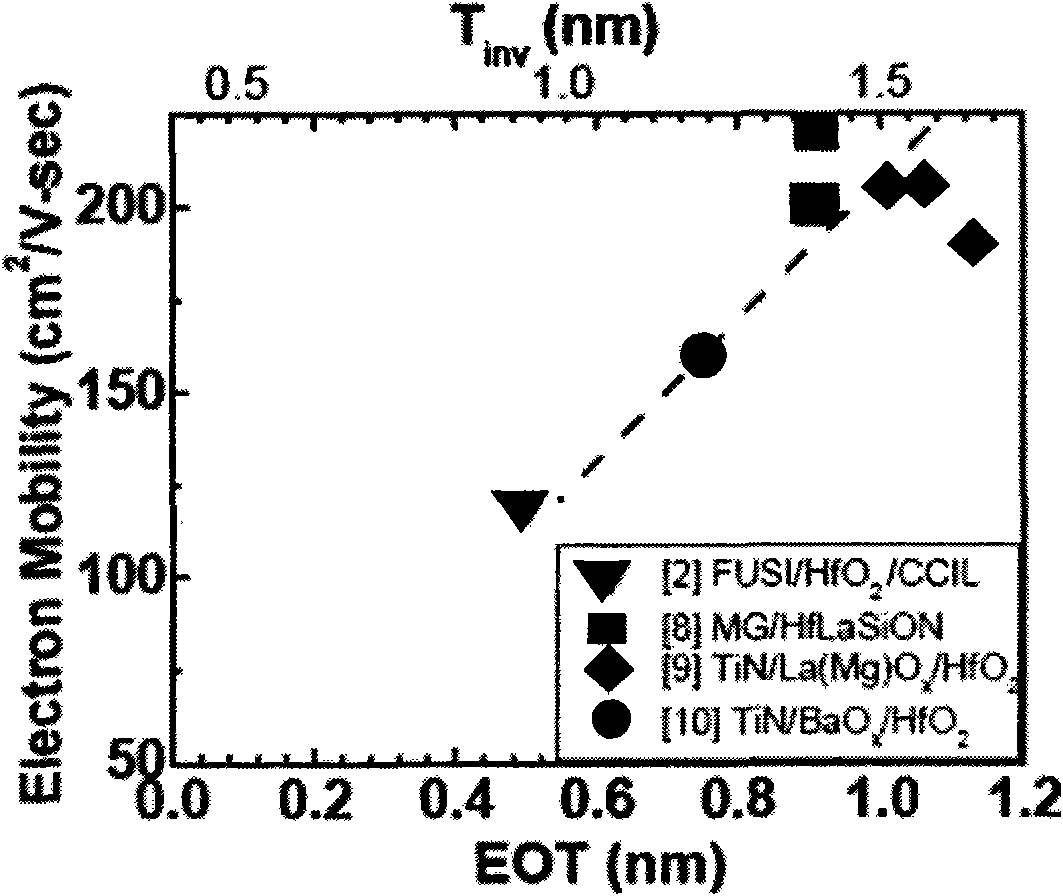

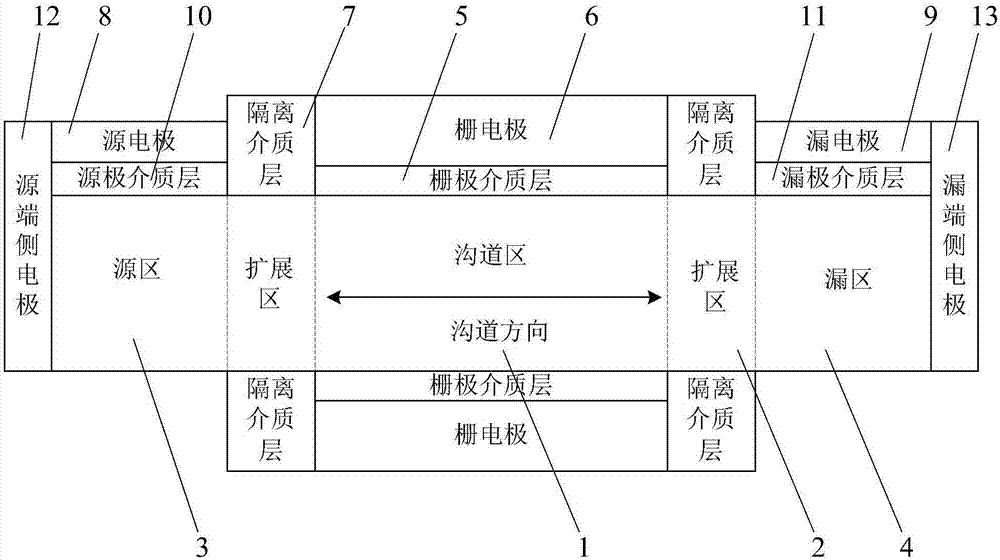

ActiveCN107068734APerformance impactImprove stabilitySemiconductor devicesGate dielectricCharge carrier

The invention provides a non-junction field-effect transistor. The non-junction field-effect transistor includes a source region and a drain region, wherein the source region and the drain region are arranged at two sides of a channel region in a central symmetry manner; the channel region, the source region and the drain region are the same in the doping type and the doping concentration; the channel region is provided with a gate dielectric layer and a gate electrode which is arranged on the gate dielectric layer; the source region and the drain region are respectively provided with a source electrode dielectric layer, a source electrode, a source end side electrode, a drain electrode dielectric layer, a drain electrode and a drain end side electrode; isolating dielectric layers isolate the source electrode from the gate electrode; and the work functions of the source electrode and the drain electrode are the work functions which are determined according to the doping type so as to form a conductive carrier layer on the surface of the source region and the surface of the drain region. The non-junction field-effect transistor can accumulate the corresponding type of carriers on the source region and the drain region to perform current transportation by adjusting the metal work functions of the source electrode and the drain electrode. The structure of the non-junction field-effect transistor can restrain the influence of rough edge of a technological fluctuation line on the device performance, can maintain the current driving capability of a non-junction device, and can optimize the subthreshold feature of the non-junction device so as to improve the stability of device.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

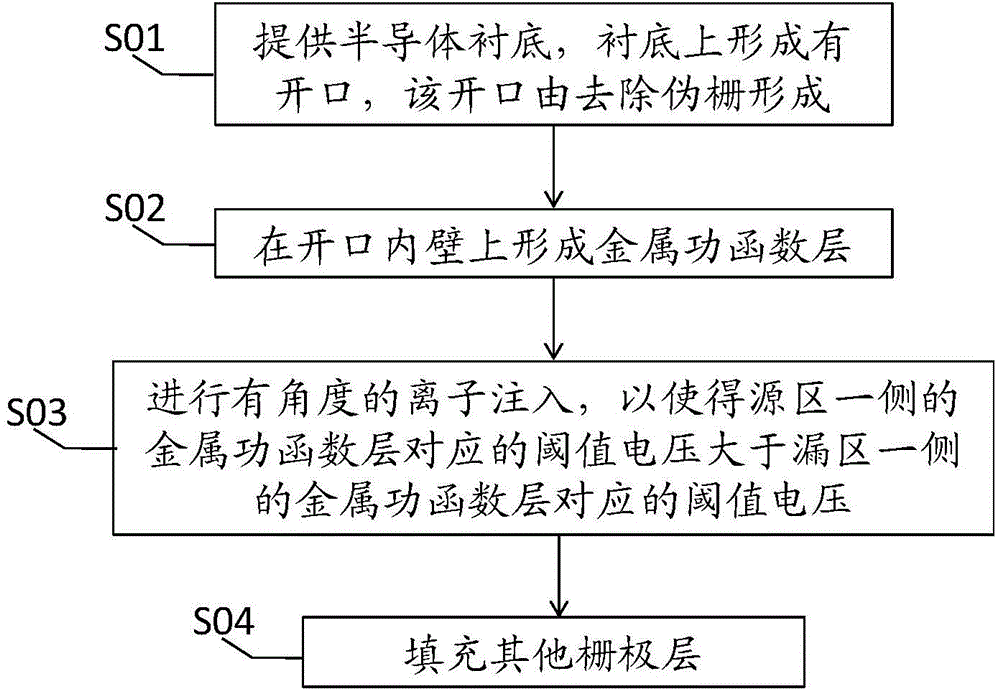

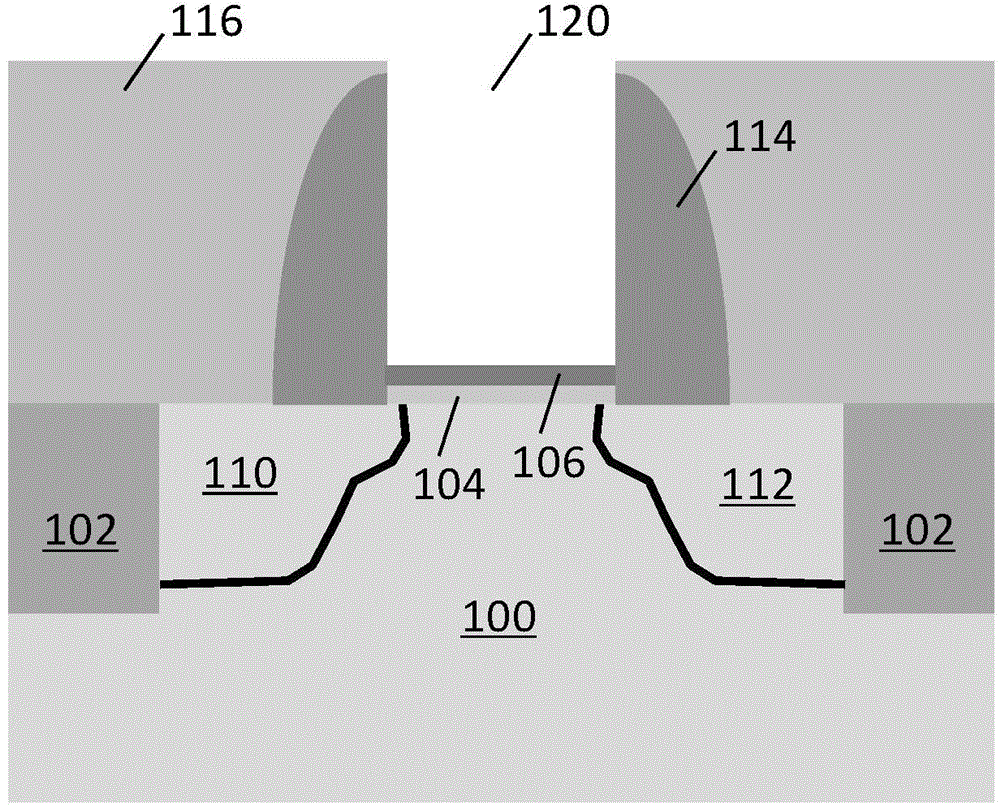

Semiconductor device and forming method of semiconductor device

InactiveCN105870020AImprove performanceImprove shipping speedSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierVoltage drop

The invention provides a manufacturing method of a semiconductor device. The method includes the following steps that: a semiconductor substrate is provided, an opening is formed in the substrate, and the opening is formed by removing a dummy gate; metal work function layers are formed at the internal wall of the opening; ion implantation of a certain angle is carried out, so that threshold voltage corresponding to a metal work function layer at one side of a source region is larger than threshold voltage corresponding to a metal work function layer at one side of a drain region; and other grid layers are filled. According to the manufacturing method of the invention, voltage drop of a channel region near a source end is increased, and voltage drop of a channel region near a drain end is decreased, and therefore, the electric field of the drain end can be decreased, and short-channel effects such as DIBL (drain induced barrier lowering) can be suppressed, and the electric field of the source end is increased, so that the transport speed of carriers can be improved, and the performance of the device can be improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

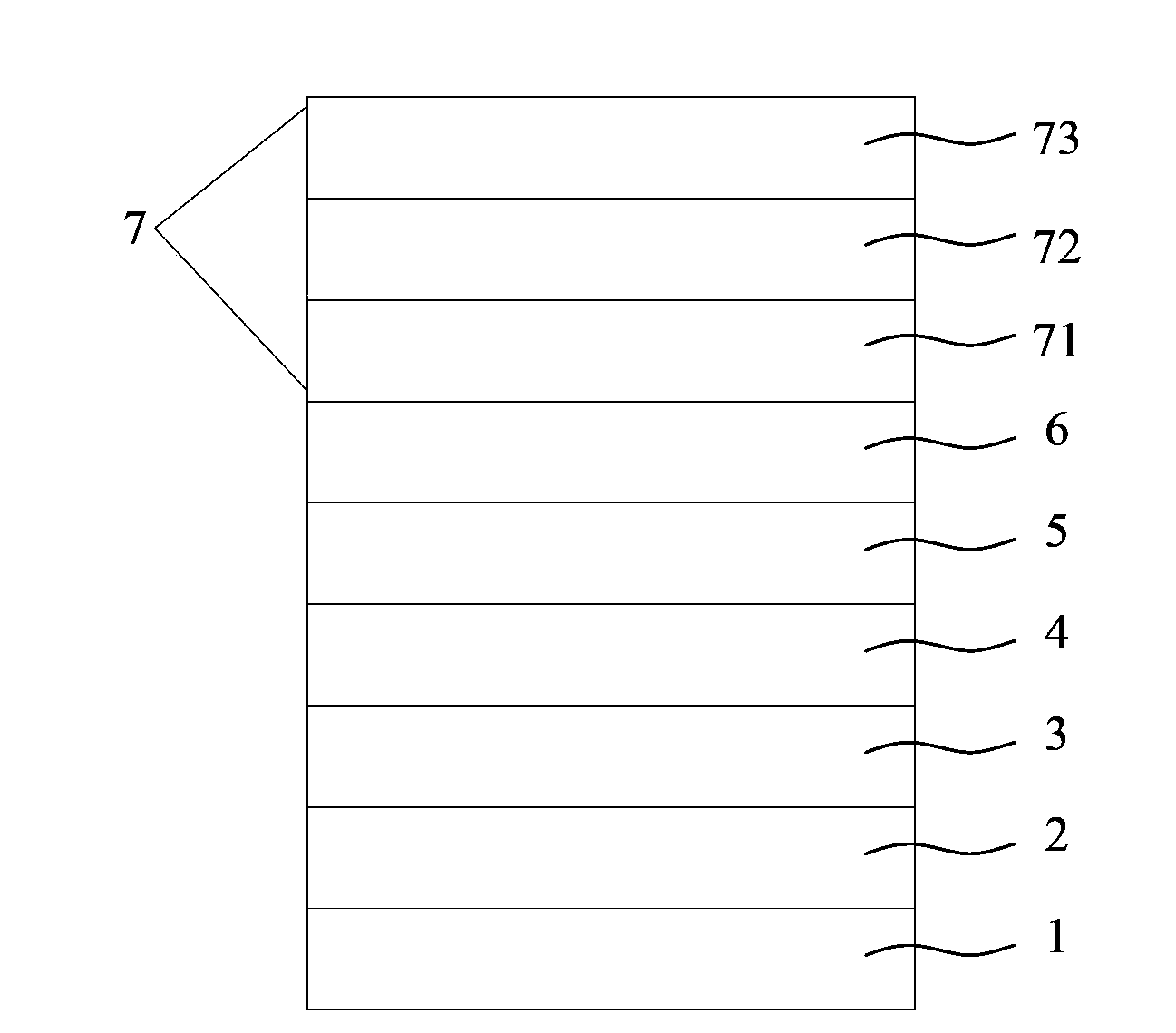

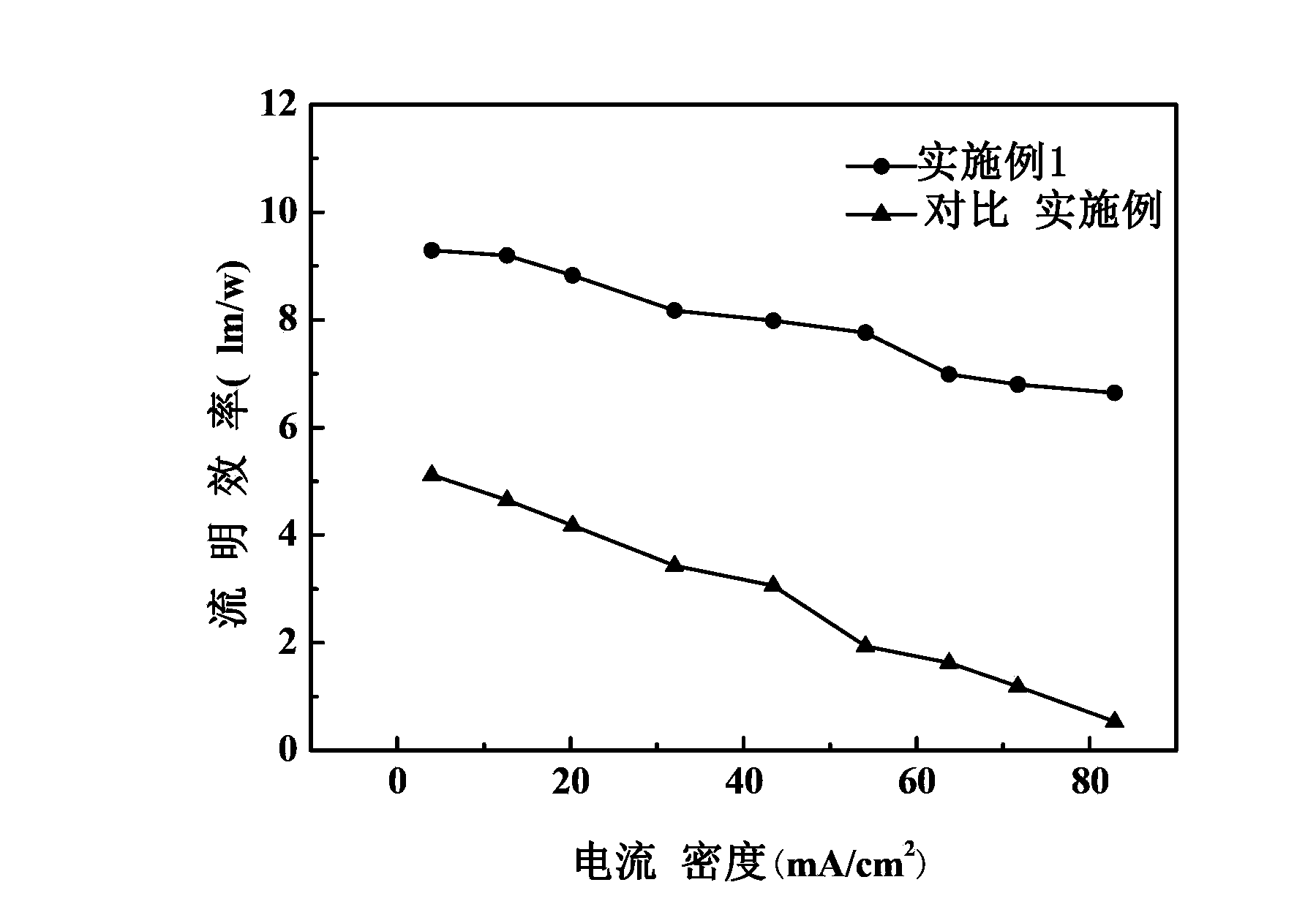

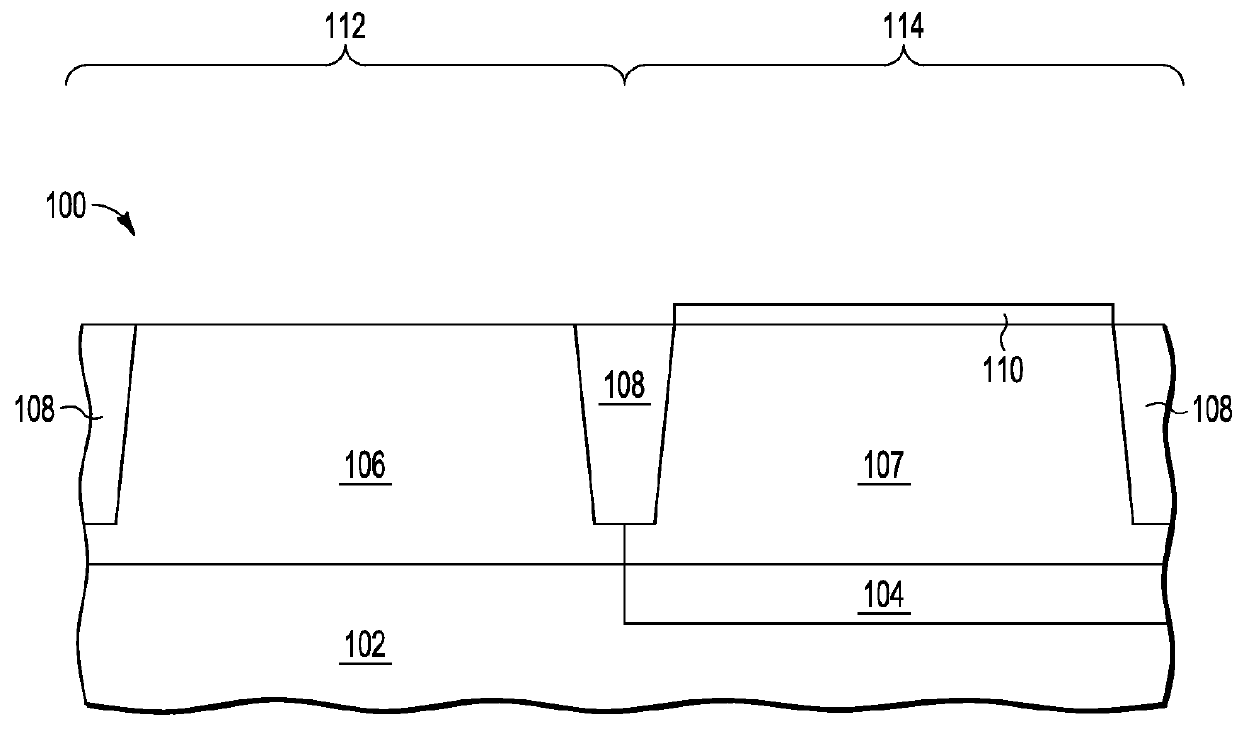

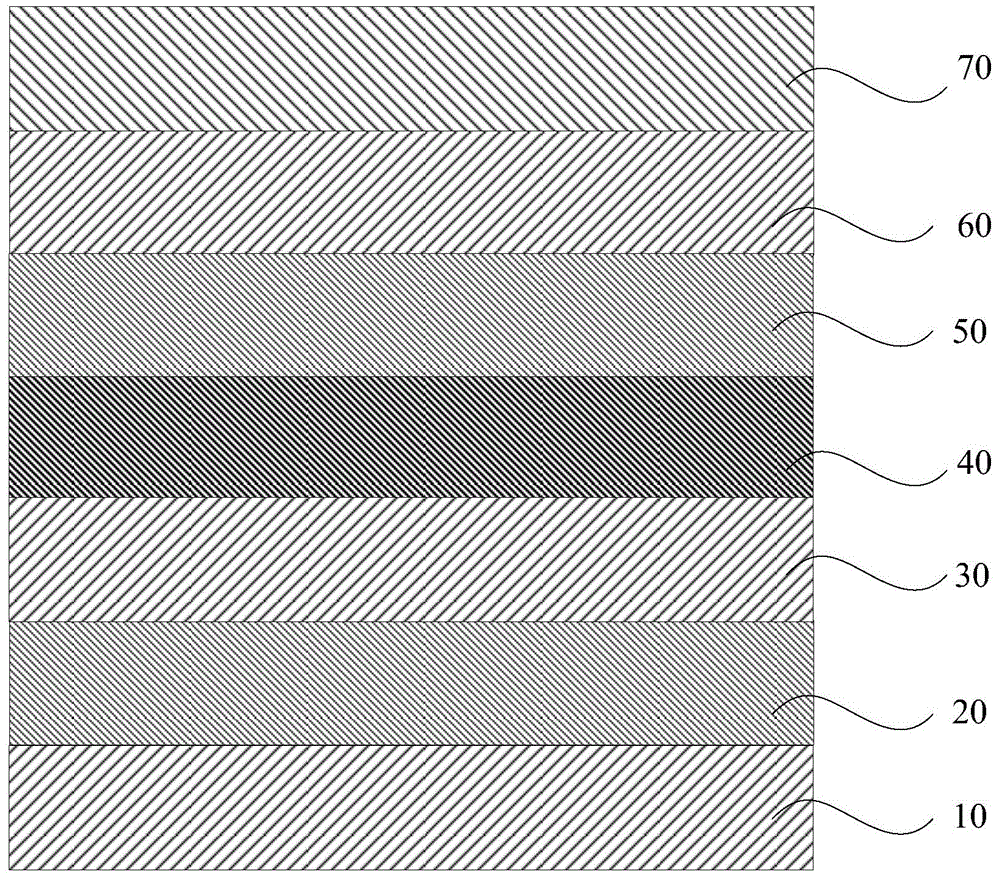

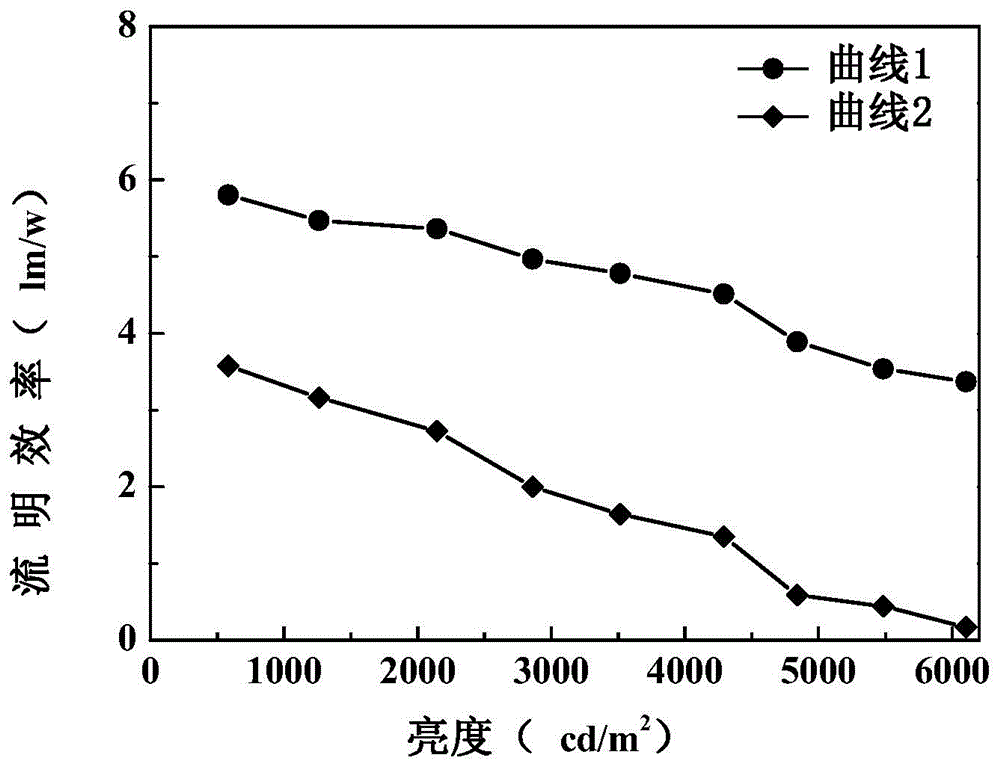

Organic light-emitting device and preparation method thereof

InactiveCN104124370AImprove luminous efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionMicrosphere

The invention discloses an organic light-emitting device and a preparation method thereof. The organic light-emitting device consists of a conductive anode glass substrate, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a composite cathode, wherein the layers are successively laminated. The composite anode includes a low-work function metal layer, a metallic oxide doping layer, and a conductive thin film layer, wherein the layers are successively laminated and the work functions of the layers are from 2.0eV to 3.5eV. The energy level difference between lowest unoccupied molecular orbital units of the low-work function metal work function and an organic layer is small, so that the electron injection capability can be effectively improved. The metallic oxide doping layer uses the metallic oxide and the silicon compound to carry out doping; the metallic oxide has high stability and the light transmittance in the visible light range is high; and the silicon compound forms a well-ordered microsphere structure after preparation, thereby carrying out scattering on the light. The conductive thin-film material can reflect the transmitted light and thus the light can be reflected to the bottom of the device; and with the composite electrode, the luminous efficiency can be effectively improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Equivalent work function adjusting method of metal grid electrode

ActiveCN104347411AEffective adjustment of equivalent work functionRealize multi-threshold adjustmentSemiconductor/solid-state device manufacturingSemiconductor devicesWork functionMetal work function

Disclosed is a method for adjusting an equivalent work function of a metal gate electrode. The method comprises: forming a metal gate electrode configuration at least comprising a metal work function layer; and performing plasma processing on at least one layer of the metal gate electrode configuration. In this way, the equivalent work function of the metal gate electrode can be adjusted in a relatively flexible manner.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

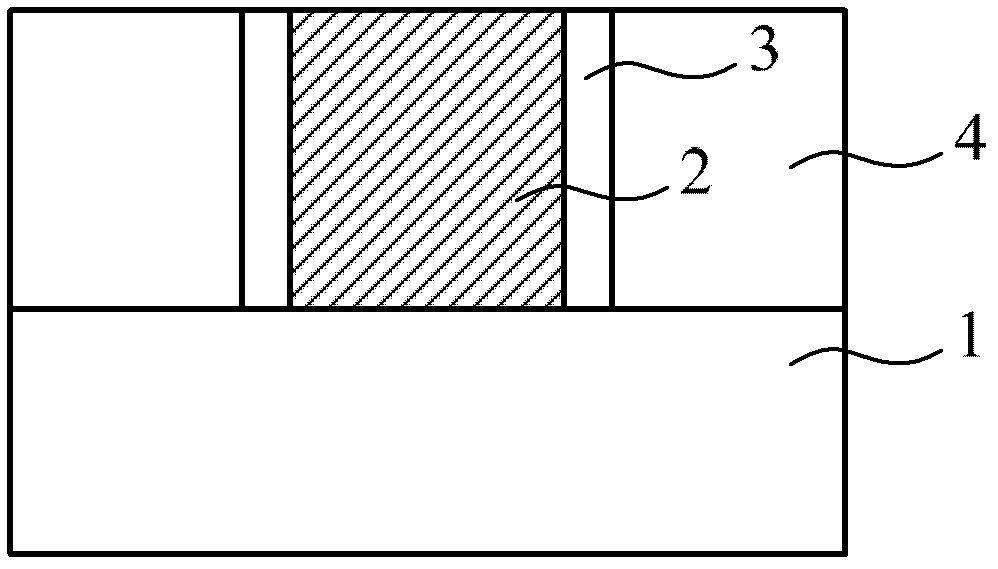

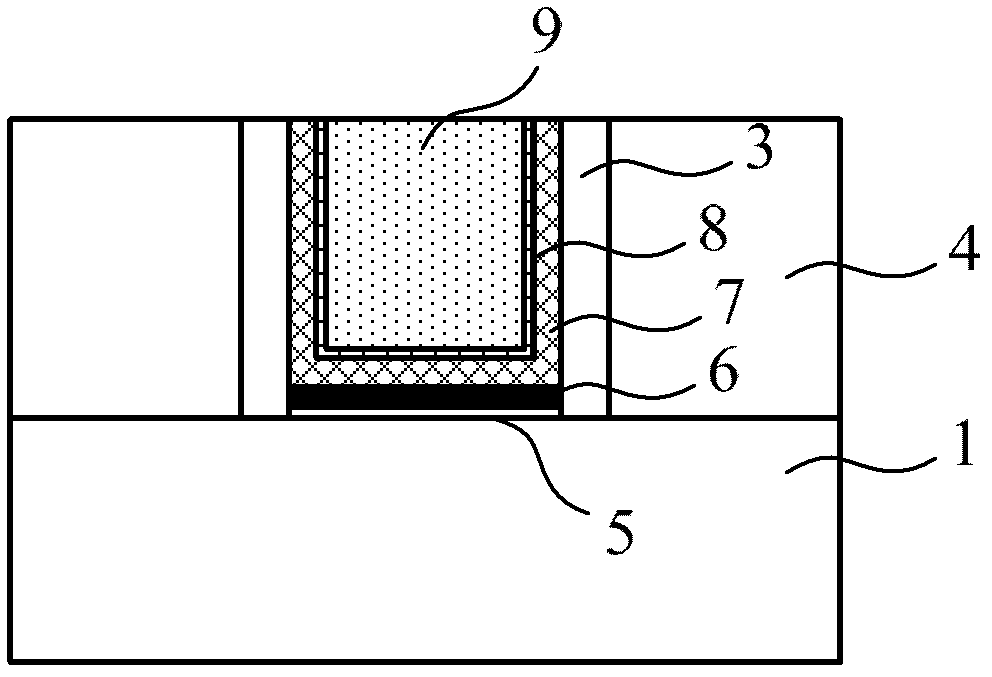

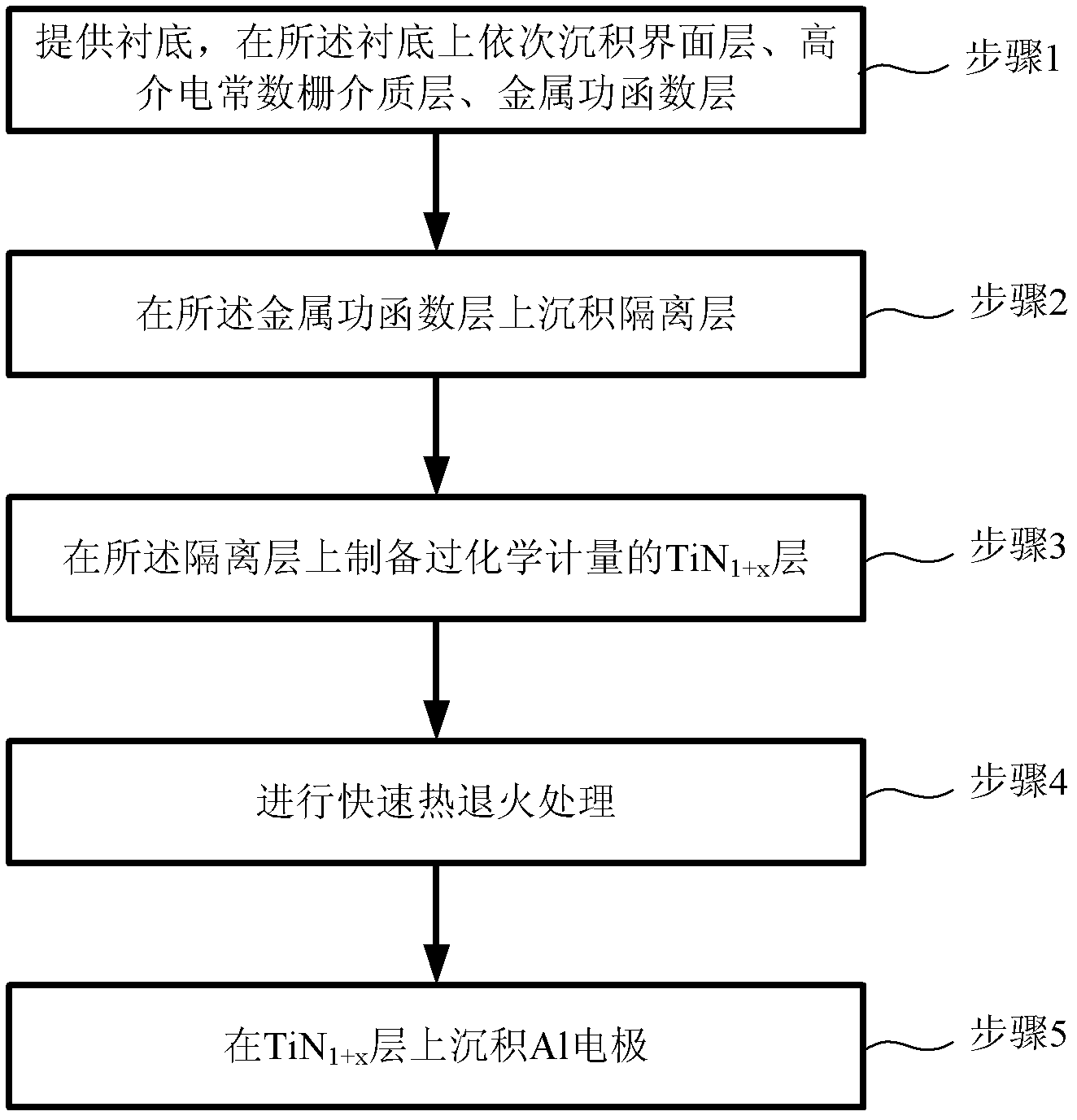

High-dielectric-constant metal gate production method

ActiveCN103177945AChange the crystal grain boundaryPrevent proliferationSemiconductor devicesHigh concentrationDielectric

The invention discloses a high-dielectric-constant metal gate production method which includes that a substrate is provided, and an interface layer, a high-dielectric-constant gate medium layer and a metal work function layer are sequentially deposited on the substrate; an isolation layer is deposited on the metal work function layer; a stoichiometric TiN1+x layer is prepared on the isolation layer; rapid thermal annealing is performed; and an Al electrode is deposited on the TiN1+x layer. According to the method, after the isolation layer is deposited, the stoichiometric TiN1+x layer is prepared on the isolation layer, high-concentration solid N is diffused in the rapid thermal annealing process, accordingly the crystal boundary of crystals of the isolation layer is changed, further the route of metal Al in the Al electrode diffusing towards the metal work function layer and the high-dielectric-constant gate medium layer is destroyed, Al electrode diffusing is avoided, and performance of semiconductor devices is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

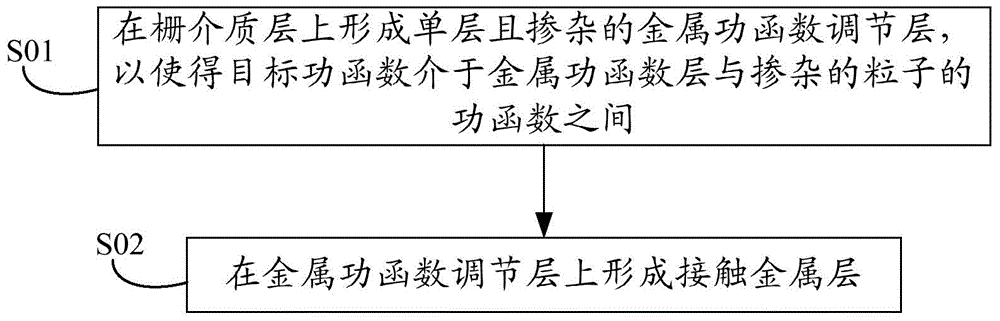

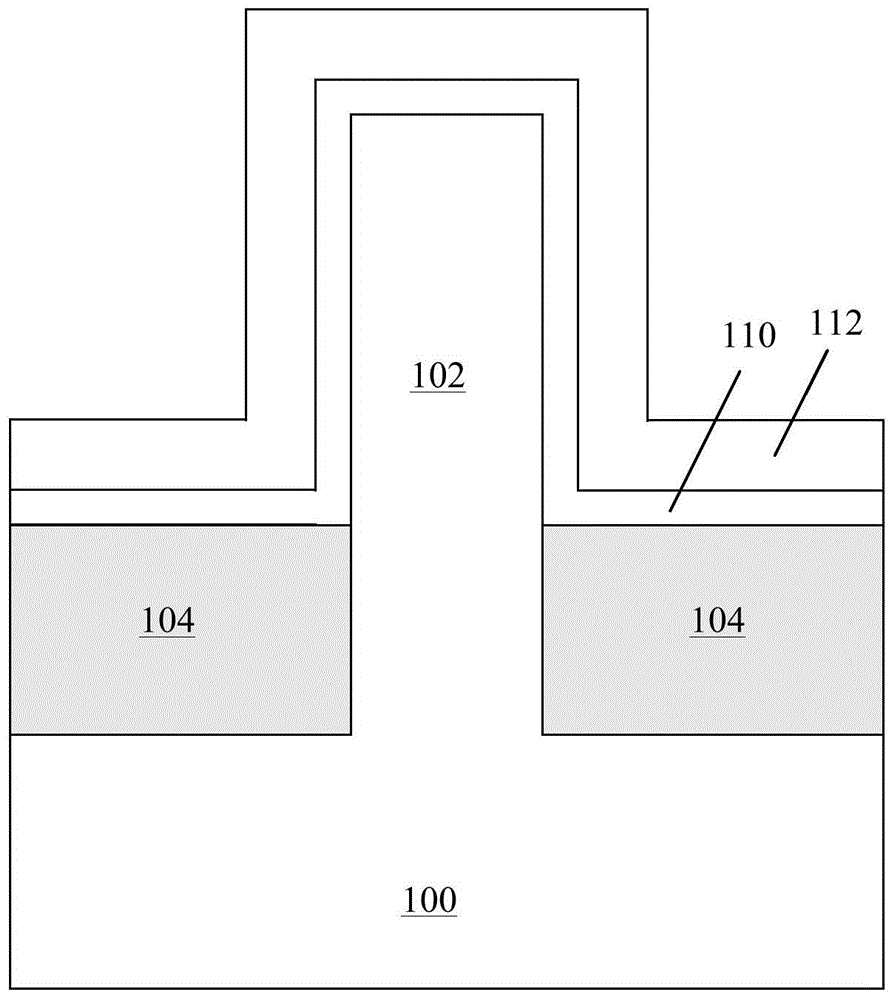

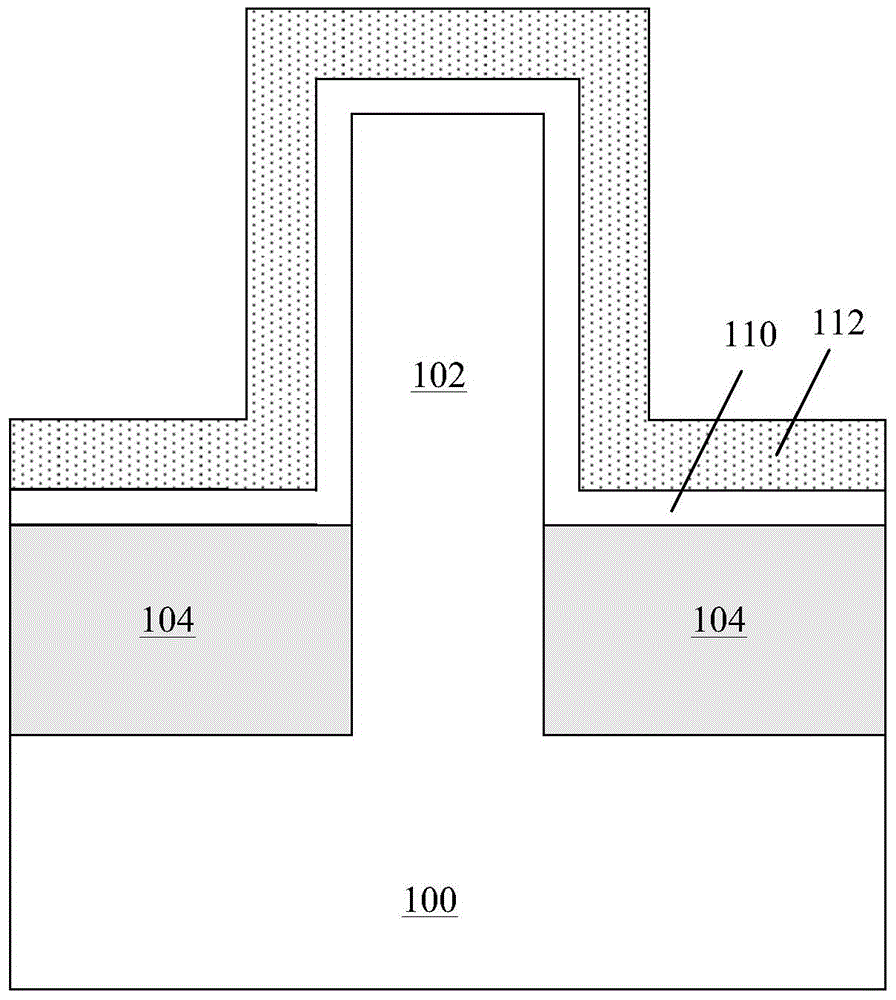

Gate and forming method thereof

ActiveCN105990403AAdjust Threshold VoltageEasy to adjustSemiconductor devicesGate dielectricWork function

The invention provides a gate forming method comprising the steps of forming a single doped metal work function adjustment layer on a gate dielectric layer to enable a target work function to be between the metal work function layer and a work function of doped particles, and forming other gate layers on the metal work function adjustment layer. Through the method, the threshold voltage can be adjusted easily, the process is simple and can be implemented without multiple metal gate layers, and the manufacturing cost is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Thin film getter activating in low temperature of uncooled focal plane detector and preparation method thereof

ActiveCN106399951AInhibition of poisoningImprove adhesionVacuum evaporation coatingSputtering coatingInfrared windowWindow opening

The invention relates to a thin film getter activating in low temperature of an uncooled focal plane detector and a preparation method thereof and the thin film getter activating in low temperature has the performance of low-temperature activation and high gas absorbing. The getter comprises an adjustable layer and an air sucking layer, wherein the adjustable layer is deposited on a window opening of the uncooled focal plane detector and the air sucking layer is deposited on the adjustable layer. The adjustable layer is made of anyone of the following metal comprising Ti, Zr, AL, Cr, Cu, Fe, Pt or Ru, and the sucking layer is made of multi-component alloy comprising the two materials of Zr and Co and at least one of the materials of Y, La and Ce. An extremely tight transition layer is formed between the adjustable layer and the window opening, the thickness of the transition layer is 20-50 nm, the thickness of the adjustable layer is 1-2 [mu]m, and the thickness of the sucking layer is 2-5 [mu]m. The thin film getter of a porous structure is adopted, the transition layer is relatively-extremely tight, and is relatively matched with infrared window metal work functions, so that the adhesive force of the thin film getter on a substrate is reinforced.

Owner:KUNMING INST OF PHYSICS

Methods to enhance effective work function of mid-gap metal by incorporating oxygen and hydrogen at a low thermal budget

A process is disclosed of forming metal replacement gates for PMOS transistors with oxygen in the metal gates such that the PMOS gates have effective work functions above 4.85. Metal work function layers in the PMOS gates are oxidized at low temperature to increase their effective work functions to the desired PMOS range. Hydrogen may also be incorporated at an interface between the metal gates and underlying gate dielectrics. Materials for the metal work function layers and processes for the low temperature oxidation are disclosed.

Owner:TEXAS INSTR INC

A junctionless field effect transistor

ActiveCN107068734BPerformance impactImprove stabilitySemiconductor devicesGate dielectricEngineering

The invention provides a non-junction field-effect transistor. The non-junction field-effect transistor includes a source region and a drain region, wherein the source region and the drain region are arranged at two sides of a channel region in a central symmetry manner; the channel region, the source region and the drain region are the same in the doping type and the doping concentration; the channel region is provided with a gate dielectric layer and a gate electrode which is arranged on the gate dielectric layer; the source region and the drain region are respectively provided with a source electrode dielectric layer, a source electrode, a source end side electrode, a drain electrode dielectric layer, a drain electrode and a drain end side electrode; isolating dielectric layers isolate the source electrode from the gate electrode; and the work functions of the source electrode and the drain electrode are the work functions which are determined according to the doping type so as to form a conductive carrier layer on the surface of the source region and the surface of the drain region. The non-junction field-effect transistor can accumulate the corresponding type of carriers on the source region and the drain region to perform current transportation by adjusting the metal work functions of the source electrode and the drain electrode. The structure of the non-junction field-effect transistor can restrain the influence of rough edge of a technological fluctuation line on the device performance, can maintain the current driving capability of a non-junction device, and can optimize the subthreshold feature of the non-junction device so as to improve the stability of device.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

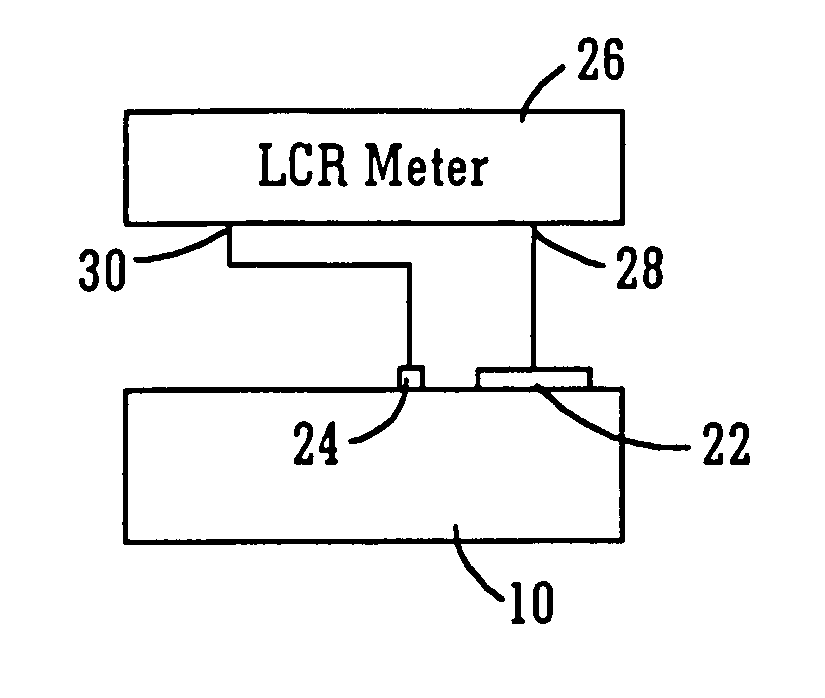

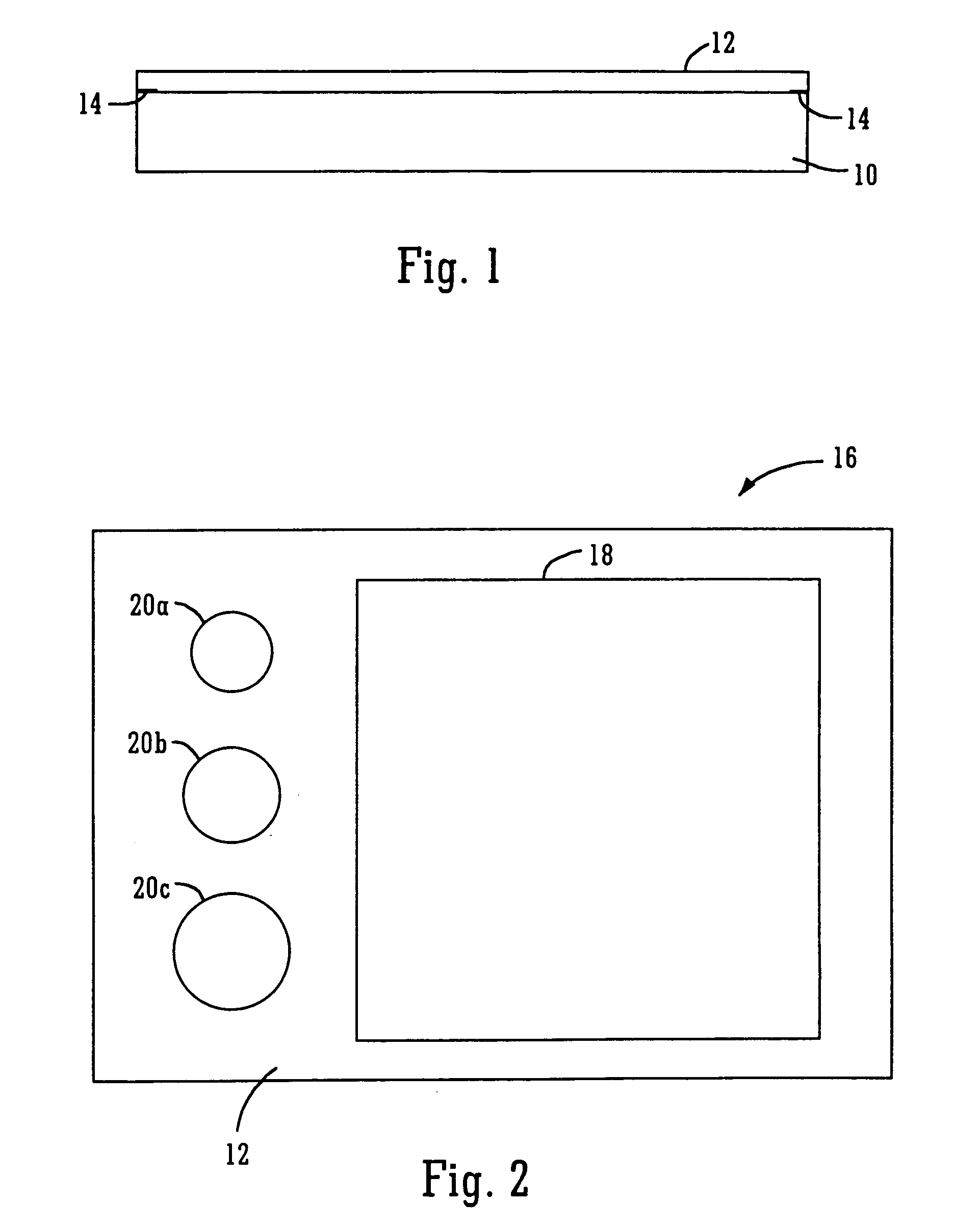

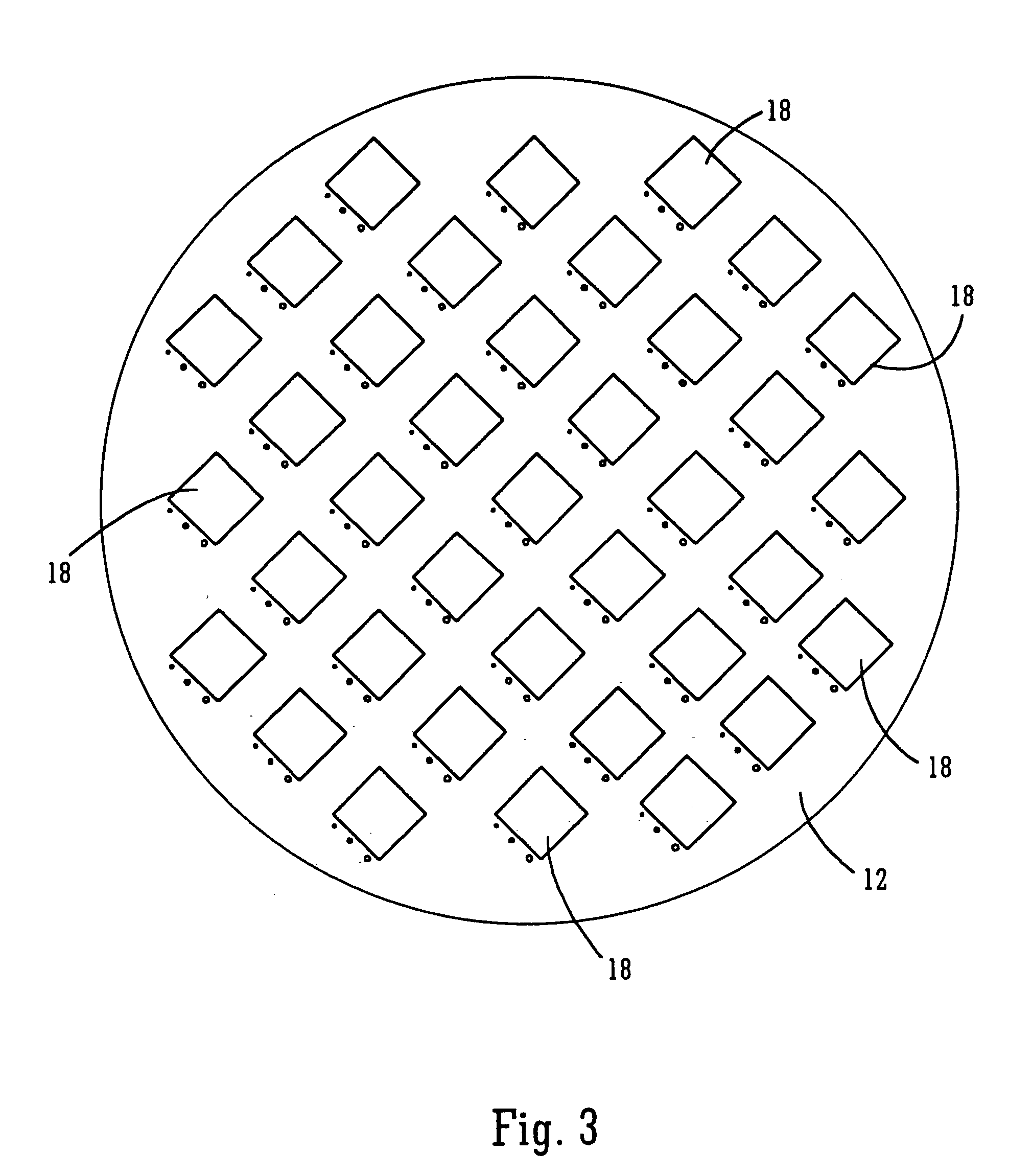

Method for determining metal work function by formation of Schottky diodes with shadow mask

InactiveUS7045384B1Reduce expensesShorten the timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWork functionMetal work function

A method of determining a work function of a metal to be used as a metal gate material provides a metal-on-silicon (MS) Schottky diode on a silicon substrate. The MS Schottky diode is formed by deposition of the metal in a single step deposition through a shadow mask that is secured on the silicon substrate.

Owner:GLOBALFOUNDRIES US INC

High dielectric constant metal gate MOS transistor

PendingCN114823893AAvoid driftingOxygen diffusion pathways are reduced or eliminatedTransistorSemiconductor/solid-state device manufacturingDielectricGate dielectric

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

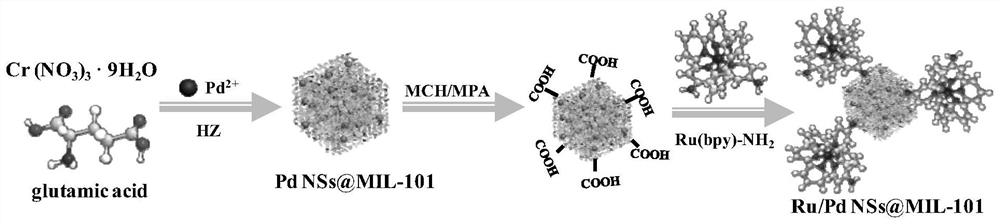

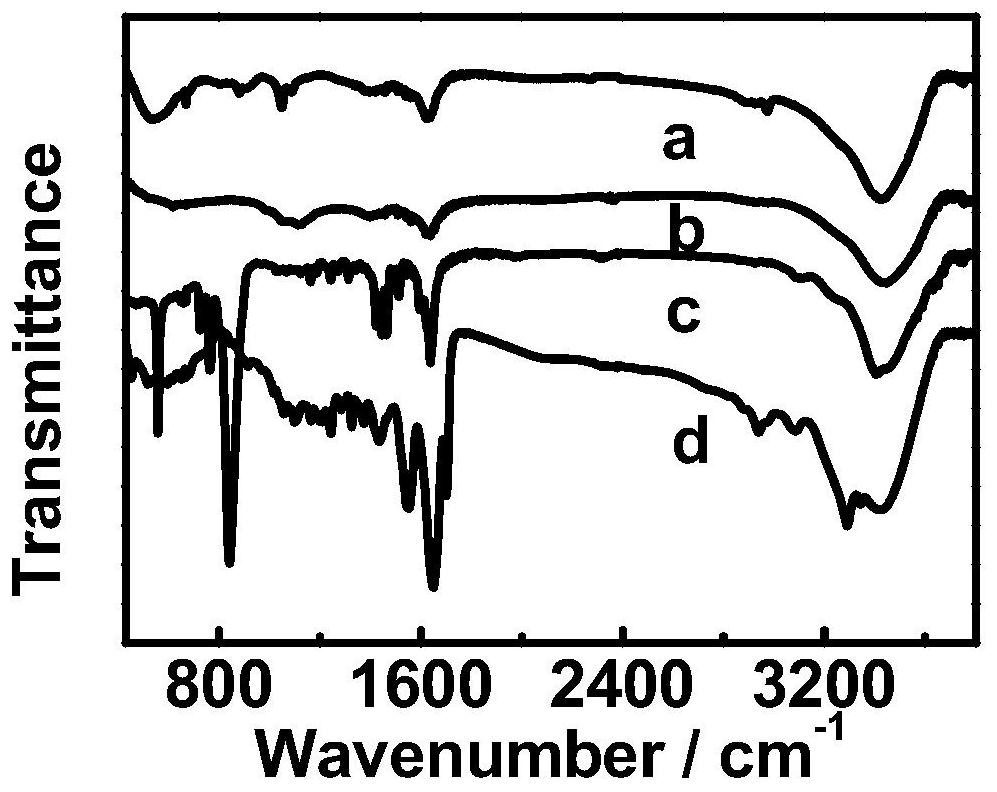

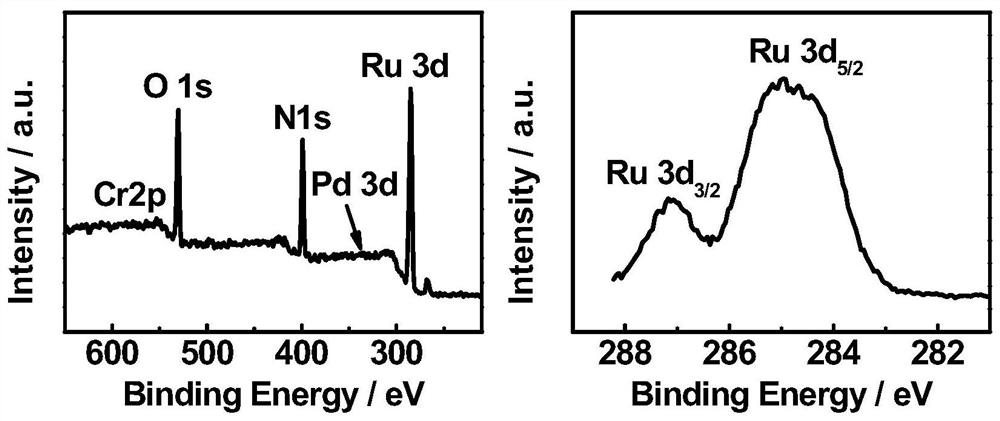

Preparation method of electrochemiluminescence nano illuminant based on aminated bipyridyl ruthenium

ActiveCN111978948AAvoid soluble inReduced Intensity LeakageChemiluminescene/bioluminescenceLuminescent compositionsElectrochemiluminescenceMetal work function

The invention relates to a preparation method of an electrochemiluminescence (ECL) nano illuminant based on aminated bipyridyl ruthenium (Ru(bpy)-NH2). The invention provides a preparation method of an enhanced ECL luminescent material based on Ru(bpy)-NH2 in order to overcome the defects that existing bipyridyl ruthenium and derivatives thereof are low in ECL luminescent efficiency, prone to aggregation in a water phase, unstable in intermediate, difficult to be directly applied to a solid-state sensing platform and the like. According to the method, Pd<2+> is subjected to in-situ reduction on the surface of MIL-101(Cr) to synthesize Pd NSs@MIL-101 on the basis of a palladium metal work function, an excited state energy level of Ru(bpy)-NH2 and a principle that excited potentials of the palladium metal work function and the Ru(bpy)-NH2 are close to each other, so that the efficient ECL nanometer illuminant (Ru / Pd NSs@MIL-101) is formed. The prepared material is stable in luminescence,high in strength and simple in biological modification, and can be applied to the solid-state sensing platform.

Owner:ZHEJIANG NORMAL UNIVERSITY

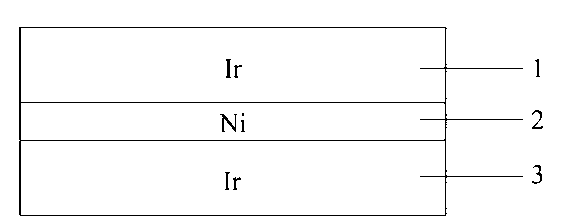

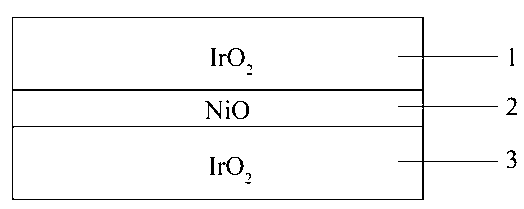

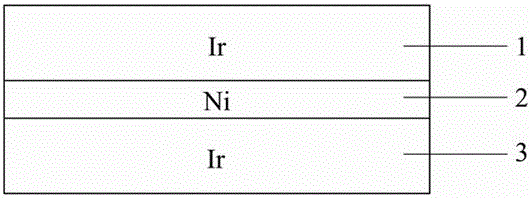

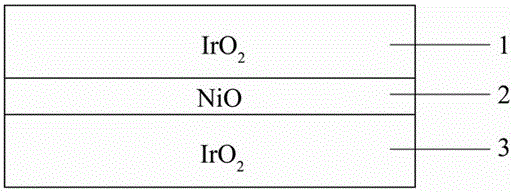

Thin film structure transparent electrode and preparation method thereof

InactiveCN102916103AEasy to make ohmic contact with small contact resistanceHigh melting pointSemiconductor devicesOhmic contactTransmittance

The invention discloses a thin film structure transparent electrode and a preparation method thereof. The thin film structure transparent electrode comprises a metal iridium in Schottky contact with an n-type semiconductor or iridium oxide in ohmic contact with a p-type semiconductor; a metal nickel is added into the metal iridium to form a metal iridium-metal nickel-metal iridium product; and nickel oxide is added into the iridium oxide to form an iridium oxide-nickel oxide-iridium oxide product. The thin film structure transparent electrode has the advantages of large metal work function, high melting point, good heat stability, good light transmittance, strong corrosion resistance, excellent resistance to oxidation and the like.

Owner:SUN YAT SEN UNIV

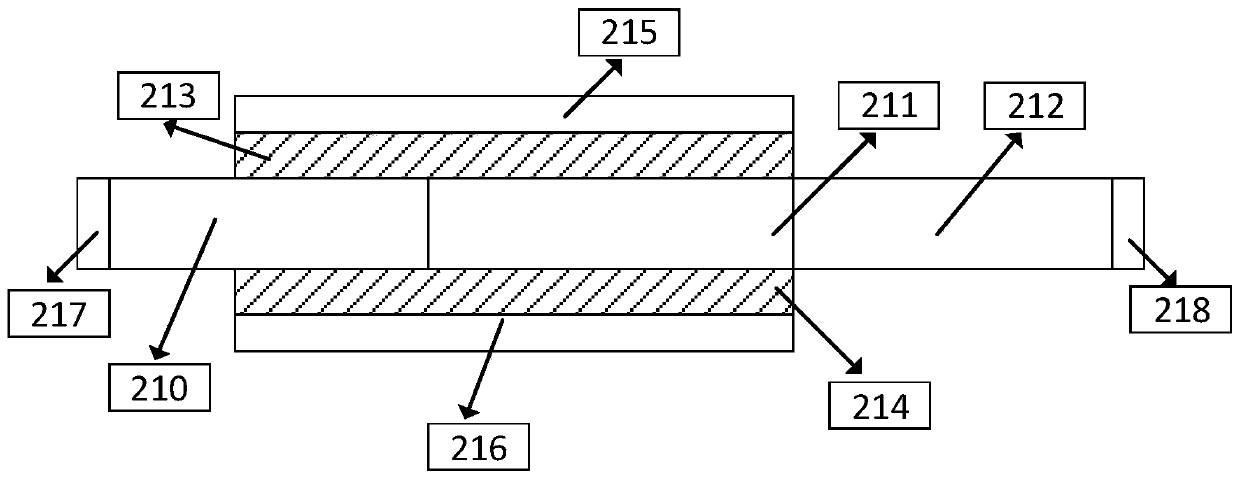

Tunneling field effect transistor capable of effectively increasing on-state current

ActiveCN109980015AIncrease the on-state currentHigh strengthSemiconductor devicesNon symmetricGate dielectric

The invention discloses a tunneling field effect transistor capable of effectively increasing the on-state current, which belongs to the field of semiconductor devices and is used for increasing the on-state current of the tunneling field effect transistor. According to the invention, upper and lower gate dielectric layers of the tunneling field effect transistor extend to a source region and partially cover the source region, the surface of the gate dielectric layer at one side of the source region is covered with a metal gate, the surface of the gate dielectric layer at the other side of thesource region is covered with a bias electrode, the bias electrode is isolated from a metal gate at the side by an isolation wall so as to form a vertically asymmetrical structure, the electric fieldperpendicular to the channel direction on the upper and lower sides of the source region covered by the gate electrode is enhanced through externally applying bias voltage to the bias electrode or utilizing the difference of a metal work function between the bias electrode and the metal gate, the intensity of carrier line tunneling is improved, and the total carrier tunneling area and tunneling probability are increased, so that the on-state current of the device is effectively increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

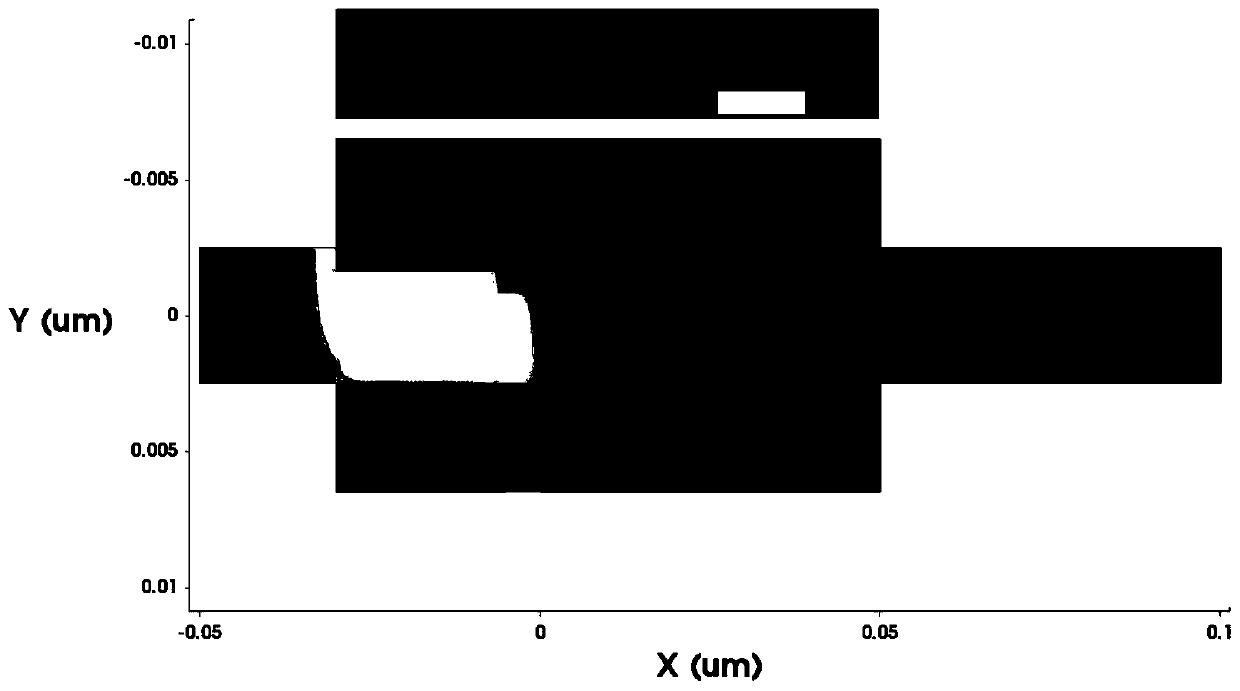

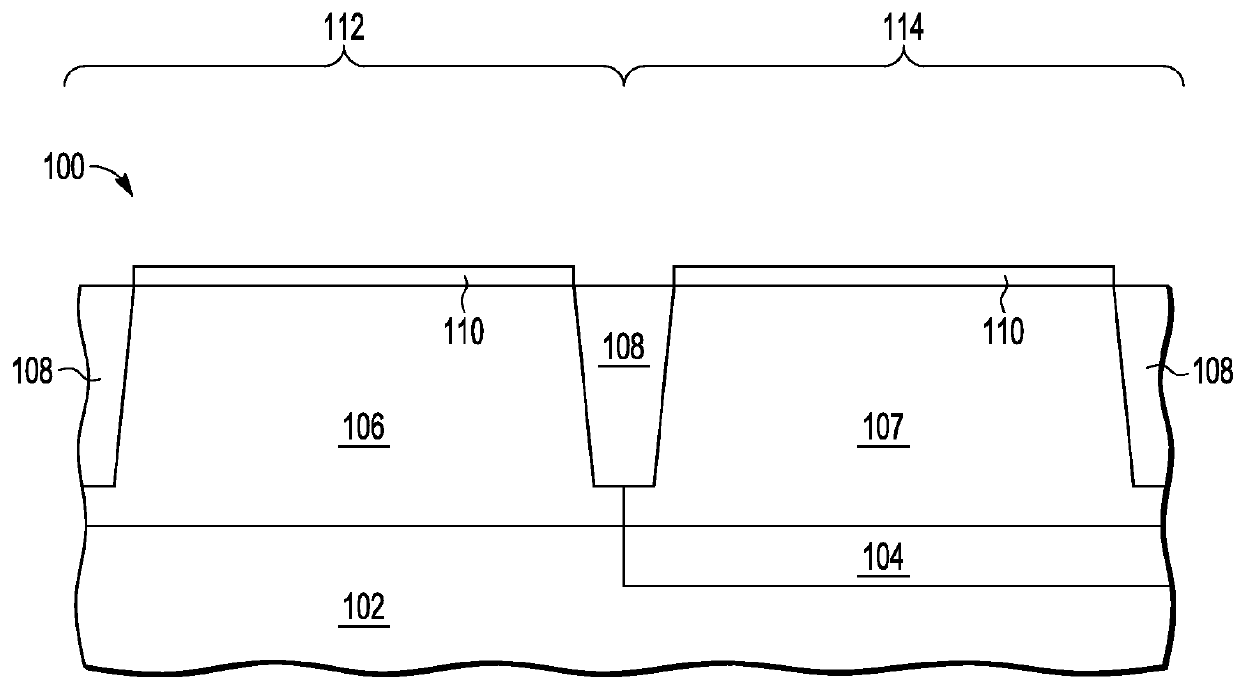

Integrated split gate non-volatile memory cell and logic device

ActiveUS9252246B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureLogic gate

A method of making a semiconductor structure includes forming a select gate and a charge storage layer in an NVM region. A control gate is formed by depositing a conformal layer followed by an etch back. A patterned etch results in leaving a portion of the charge storage layer over the select gate and under the control gate and to remove the charge storage layer from the logic region. A logic gate structure formed in a logic region has a metal work function surrounded by an insulating layer.

Owner:NXP USA INC

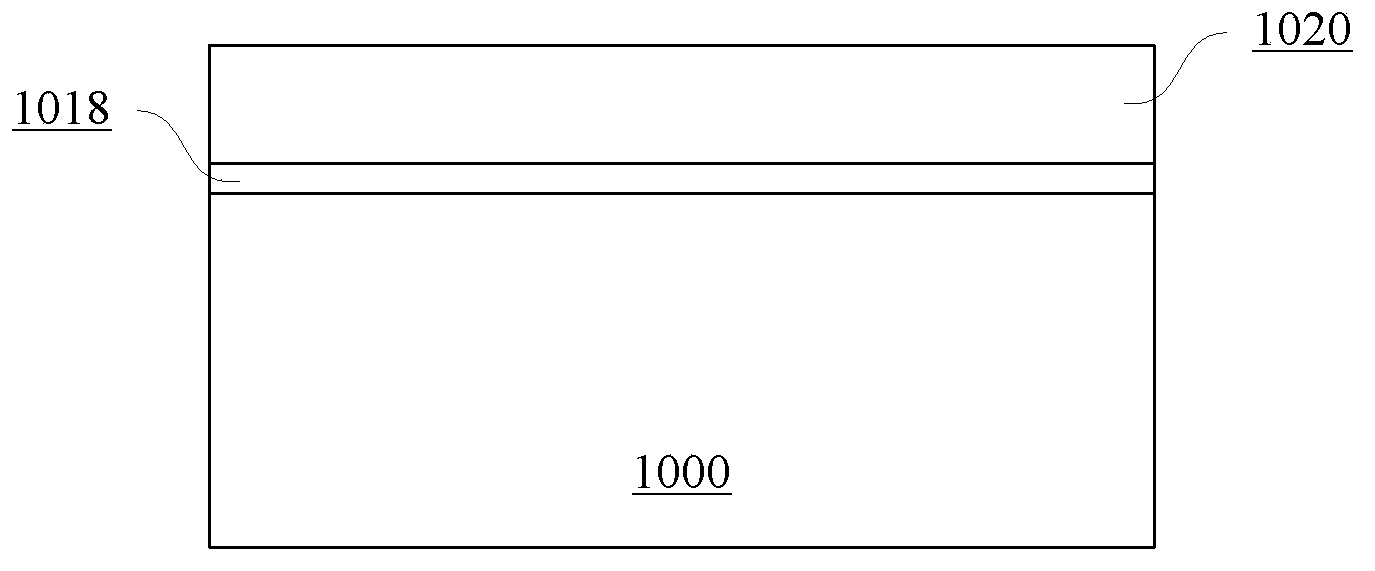

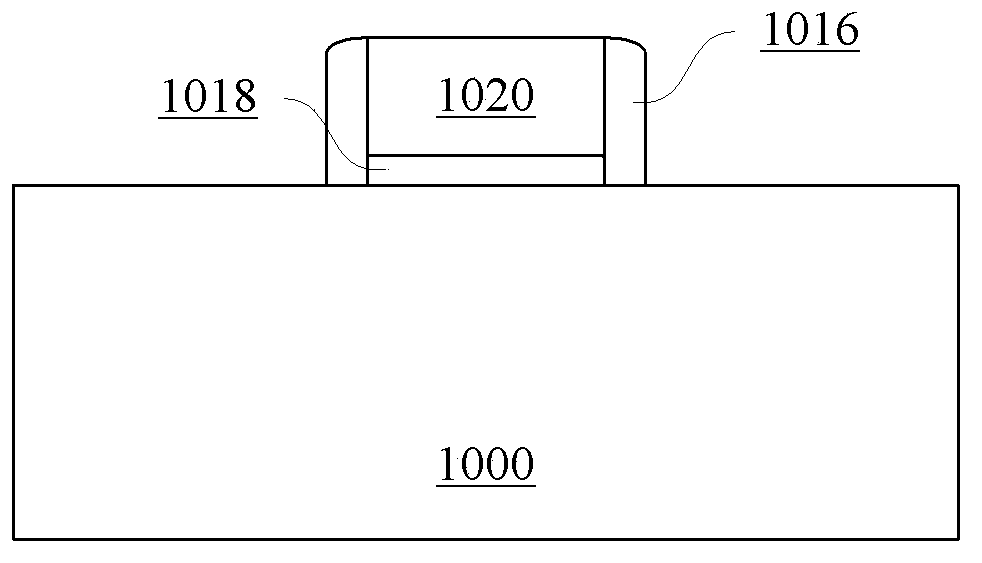

Organic electroluminescent device and preparation method thereof

InactiveCN104425725AImprove light extraction efficiencyEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionComposite cathode

The invention discloses an organic electroluminescent device, including a conductive anode substrate, a hole injection layer, a hole transport layer, a luminous layer, an electron transport layer, an electron injection layer and a composite cathode which are stacked in sequence. The material of the composite cathode is a mixture of low work function metal, ferric salt and passivation material. According to the organic electroluminescent device, the composite cathode whose material is the mixture of low work function metal, ferric salt and metal passivation material is prepared on the electron injection layer, the light extraction efficiency is improved, the work function of the low work function metal is relatively low, thereby facilitating electron injection, and improving electron injection efficiency, at the same time, light can be scattered, emitted light is reflected back to the bottom to be emitted, and the light extraction efficiency is improved. Compared with a conventional organic electroluminescent device, the light extraction efficiency of the organic electroluminescent device provided by the invention is relatively high. The invention also discloses a preparation method of the abovementioned organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

High-K metal gate

ActiveUS9431509B2TransistorSemiconductor/solid-state device manufacturingGate dielectricNitrogen rich

An integrated circuit containing metal replacement gates may be formed by forming a nitrogen-rich titanium-based barrier between a high-k gate dielectric layer and a metal work function layer of a PMOS transistor. The nitrogen-rich titanium-based barrier is less than 1 nanometer thick and has an atomic ratio of titanium to nitrogen of less than 43:57. The nitrogen-rich titanium-based barrier may be formed by forming a titanium based layer over the gate dielectric layer and subsequently adding nitrogen to the titanium based layer. The metal work function layer is formed over the nitrogen-rich titanium-based barrier.

Owner:TEXAS INSTR INC

A kind of thin film structure transparent electrode and preparation method thereof

InactiveCN102916103BEasy to make ohmic contact with small contact resistanceEasy to make contactsSemiconductor devicesMetal work functionCorrosion

The invention discloses a thin film structure transparent electrode and a preparation method thereof. The thin film structure transparent electrode comprises a metal iridium in Schottky contact with an n-type semiconductor or iridium oxide in ohmic contact with a p-type semiconductor; a metal nickel is added into the metal iridium to form a metal iridium-metal nickel-metal iridium product; and nickel oxide is added into the iridium oxide to form an iridium oxide-nickel oxide-iridium oxide product. The thin film structure transparent electrode has the advantages of large metal work function, high melting point, good heat stability, good light transmittance, strong corrosion resistance, excellent resistance to oxidation and the like.

Owner:SUN YAT SEN UNIV

Method for deciding coating (or not) titanium dioxide type optical catalyst on metal surface

InactiveCN101000356AEasy to removeImprove effectivenessMaterial analysis using wave/particle radiationWork functionMetal work function

A method for judging whether it is suitable to coat titanium dioxide catalyst on metal surface or not includes comparing work function of metal with work function of titanium dioxide catalyst, confirming that it is suitable to coat titanium dioxide catalyst on metal surface if metal work function is less than work function of titanium dioxide catalyst or otherwise confirming that it is not suitable to coat titanium dioxide catalyst on metal surface.

Owner:FUZHOU UNIV

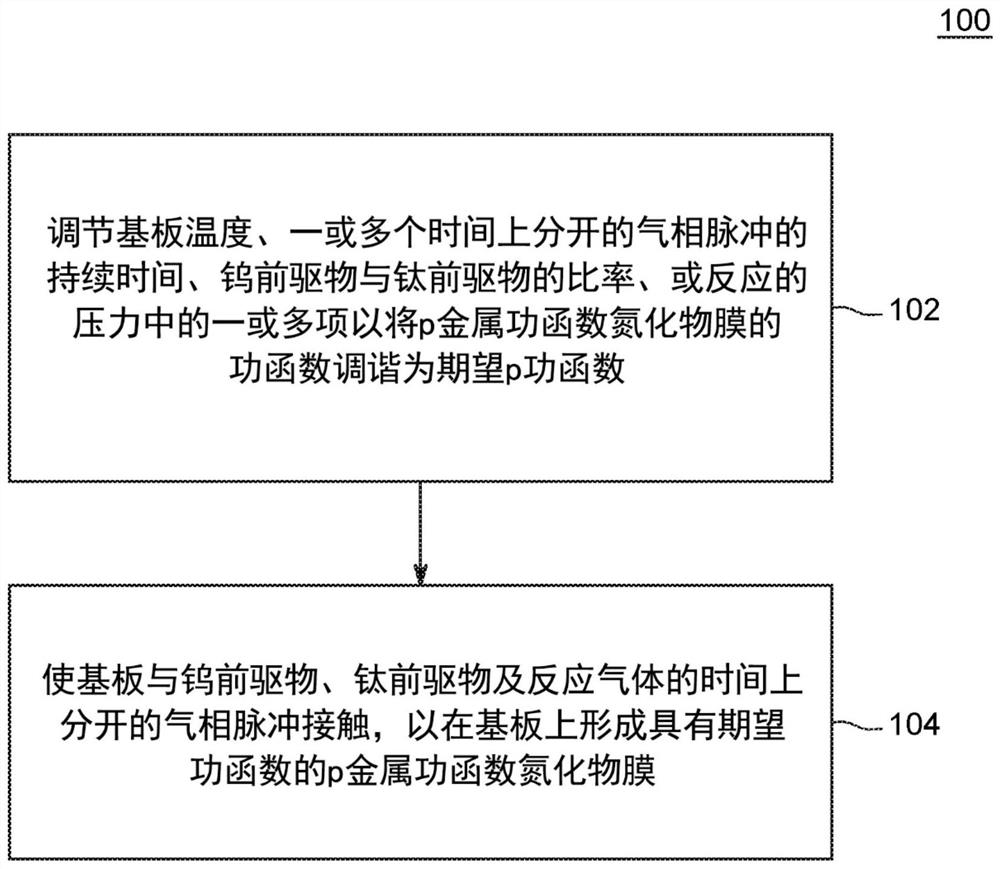

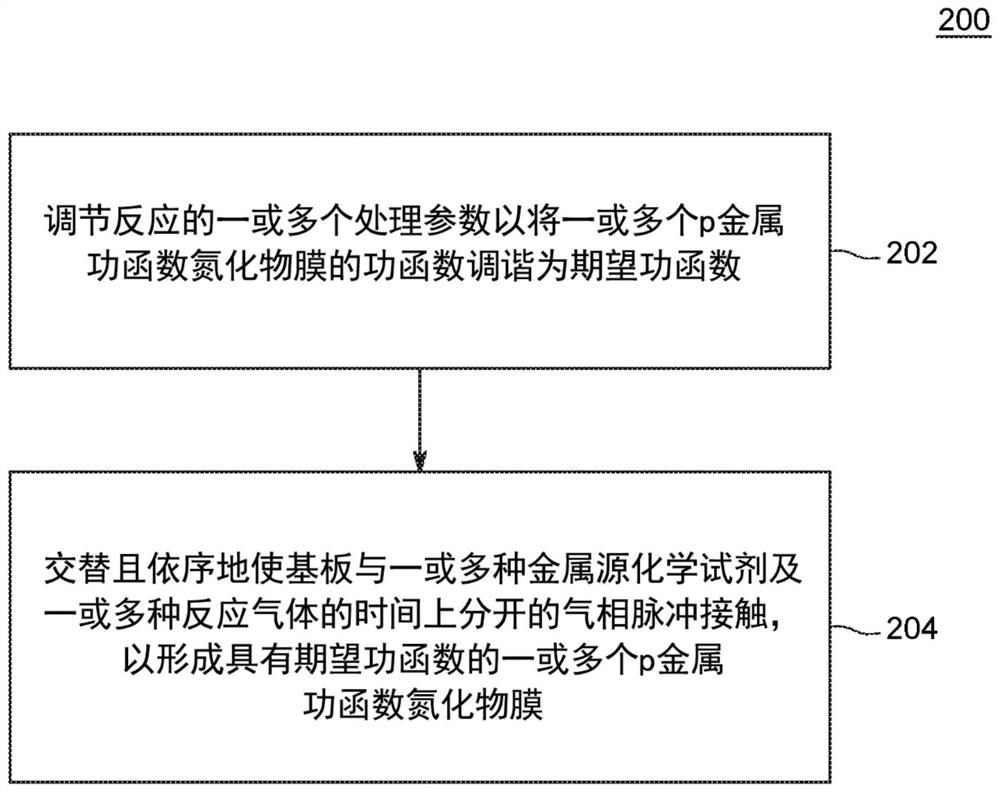

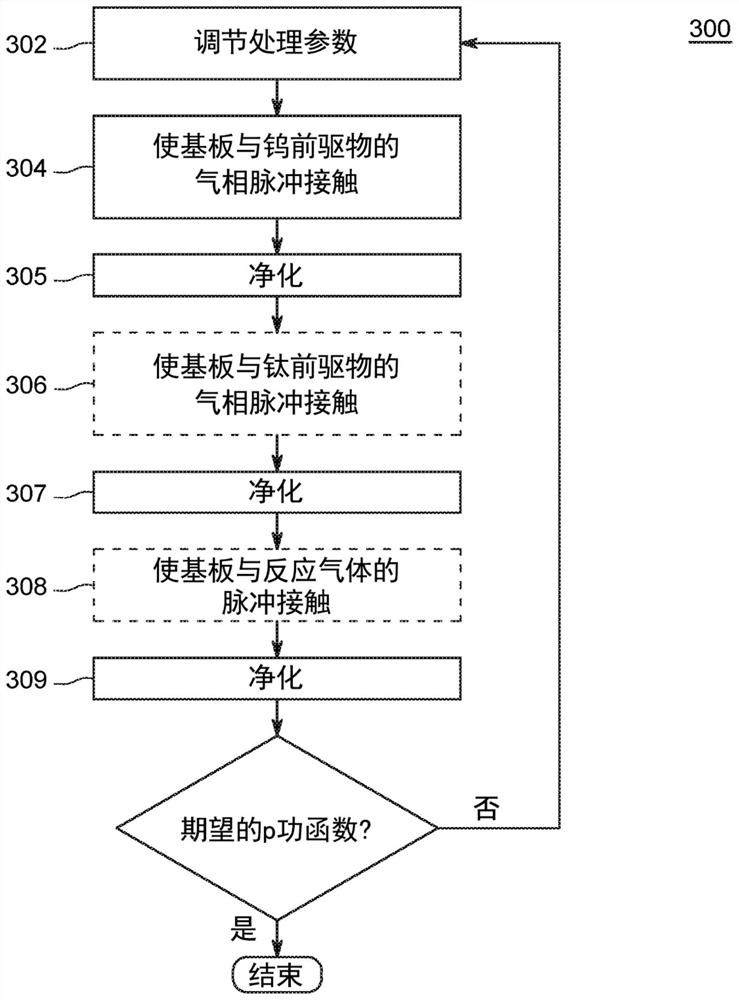

Tuning work function of p-metal work function films through vapor deposition

PendingCN111989762ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasWork function

The present disclosure relates to a method for forming a p-metal work function nitride film having a desired p-work function on a substrate, including: adjusting one or more of a temperature of a substrate, a duration of one or more temporally separated vapor phase pulses, a ratio of a tungsten precursor to a titanium precursor, or a pressure of a reaction to tune a work function of a p-metal workfunction nitride film to a desired p-work function, and contacting the substrate with temporally separated vapor phase pulses of the tungsten precursor, the titanium precursor, and a reactive gas toform a p-metal work function nitride film thereon having the desired p-work function.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com