High-dielectric-constant metal gate production method

A high dielectric constant, metal gate technology, applied in semiconductor devices and other directions, can solve problems such as affecting the performance of semiconductor devices, and achieve the effect of preventing diffusion and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

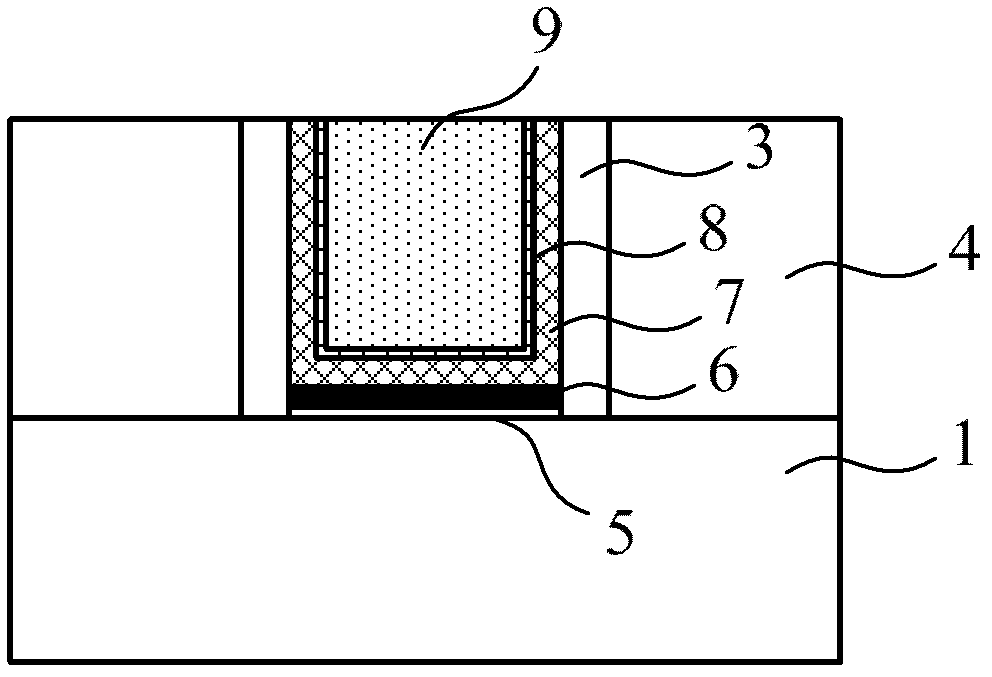

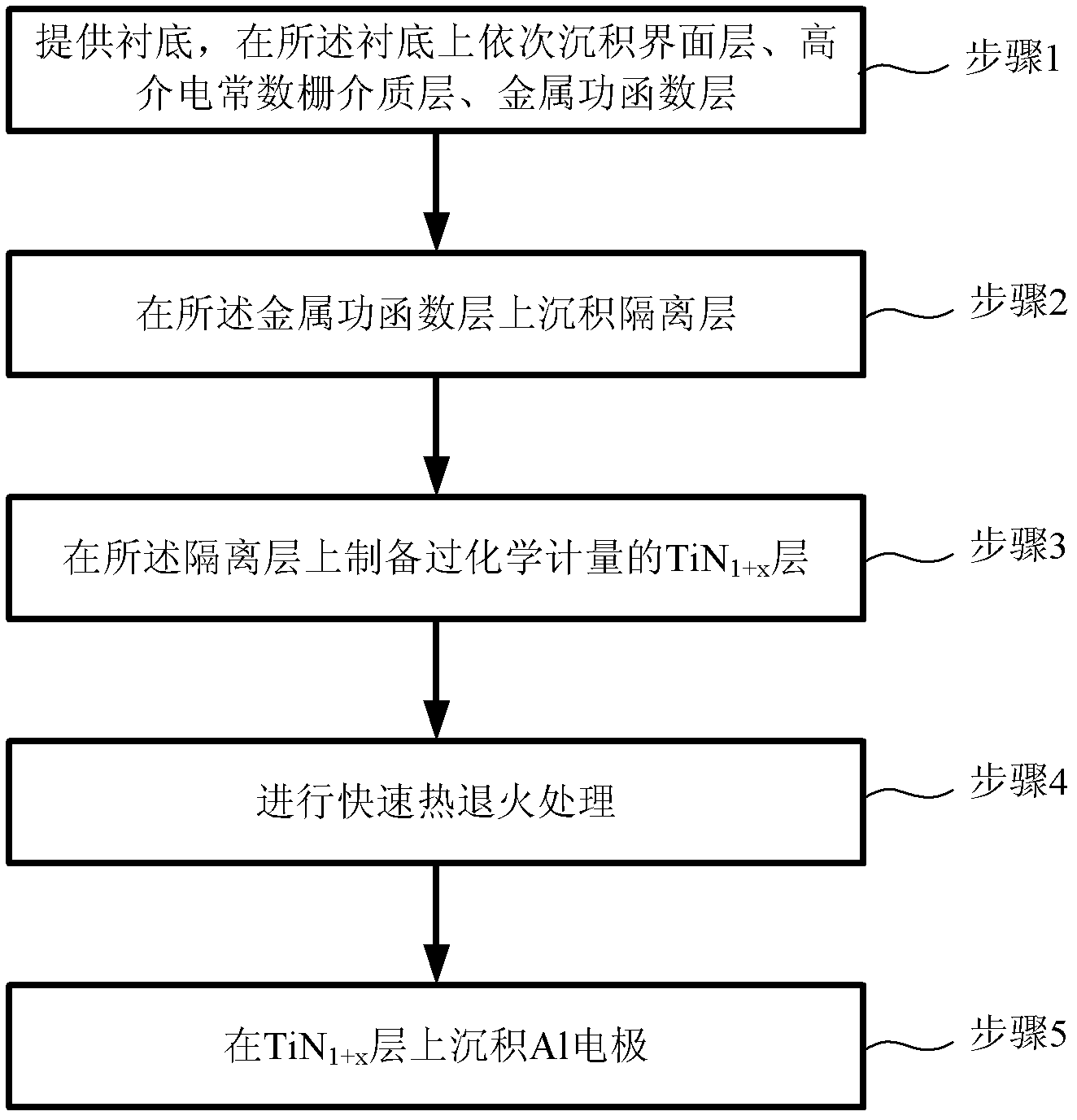

[0025] Such as image 3 shown, and refer to Figure 4 to Figure 8 , the high dielectric constant metal gate manufacturing method of the present invention, comprising:

[0026] Step 1: If Figure 4 As shown, a substrate 1 is provided, and an interface layer 5 , a high dielectric constant gate dielectric layer 6 and a metal work function layer 7 are sequentially deposited on the substrate.

[0027] The substrate 1 may include any basic material on which a semiconductor device can be built, such as a silicon substrate, or a silicon substrate on which field isolation regions have been formed, or a silicon substrate on an insulating material.

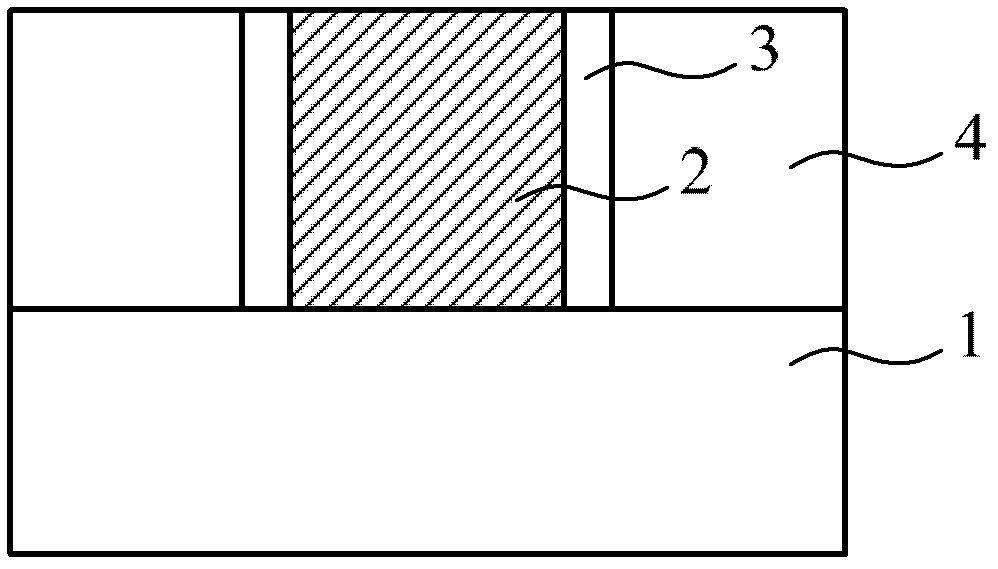

[0028] In the prior art, other necessary steps are also included before step 1. Can refer to figure 1 and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com