A junctionless field effect transistor

A field effect transistor, junctionless technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

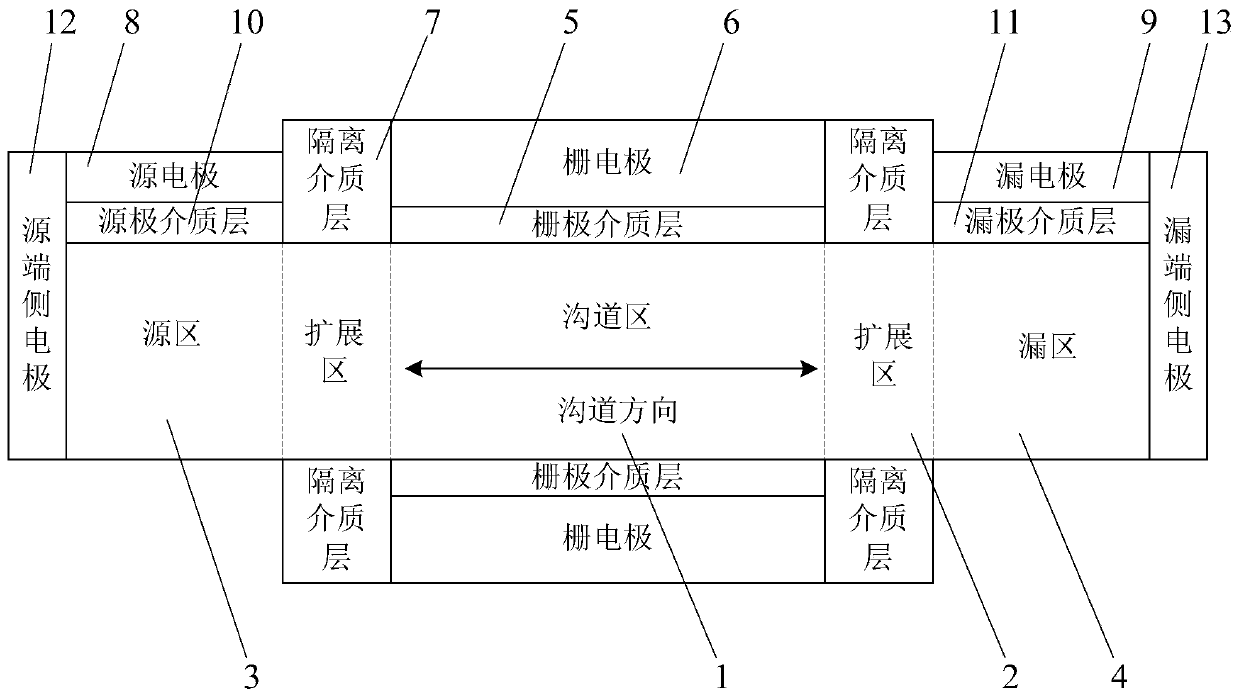

[0040] Please refer to figure 1 , Is a schematic structural diagram of a junctionless field effect transistor provided by an embodiment of the present invention, such as figure 1 As shown, the junctionless field effect transistor includes a channel region 1, a source region 3, a drain region 4, a gate electrode 6, a source electrode 8 and a drain electrode 9.

[0041] Among them, the source region 3 and the drain region 4 are centered symmetrically on both sides of the channel region 1, so that the carriers in the channel region 1 can travel from the source region 3 to the drain region 4 or from the drain region 4 to the source region 3. The direction in which the source region 3 and the drain region 4 are arranged can be understood as the channel direction to indicate the direction of carrier transport; in an exemplary embodiment, the source region 3 and the channel region 1 can also be An extension area 2 is provided, and an extension area 2 can also be provided between the drai...

Embodiment 2

[0065] On the basis of Example 1, please refer to figure 1 with Figure 5 , Is a schematic structural diagram of a tri-gate junctionless field effect transistor provided by an embodiment of the present invention. Such as Figure 5 As shown, the junctionless field effect transistor includes a channel region 1, an extension region 2, a source region 3, and a drain region 4; wherein, the channel region 1, the extension region 2, the source region 3 and the drain region 4 all include top Surface and two side surfaces, and the channel region 1, the extension region 2, the source region 3 and the drain region 4 are all arranged on the substrate 12, which can be a silicon substrate, etc., which is not limited in the embodiment of the present invention; The gate dielectric layer covers the top surface and all sides of the channel region 1, and the gate electrode 6 covers the gate dielectric layer to form a three-gate structure, thereby enhancing the control ability of the gate electrode...

Embodiment 3

[0068] On the basis of Example 1, please refer to figure 1 with Image 6 , Is a schematic diagram of the structure of a ring-gate junctionless field effect transistor provided by an embodiment of the present invention, such as Image 6 As shown, the junctionless field effect transistor includes a channel region, an extension region, a source region, and a drain region; wherein the channel region, the extension region, the source region and the drain region are all cylindrical structures; the gate dielectric layer is arranged around On the outer circumference of the channel region, the gate electrode 6 is further arranged around the outer circumference of the gate dielectric layer to form a ring-gate structure; the isolation dielectric layer 7 is arranged around the outer circumference of the extension area, thereby realizing the gap between the source electrode 8 and the gate electrode 6, And the isolation between the drain electrode 9 and the gate electrode 6; the source diele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com