Thin film structure transparent electrode and preparation method thereof

A technology of transparent electrodes and thin-film structures, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of affecting the quality of contact and increasing the number of defects in the contact interface, and achieve improved work efficiency, excellent performance, good quality, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

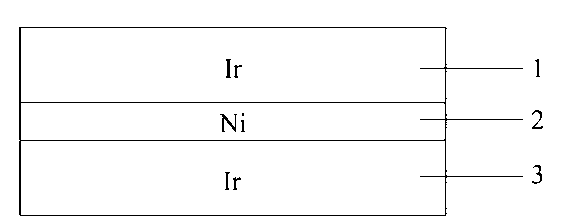

[0037] like figure 1 As shown, the present invention discloses a thin-film structure transparent electrode comprising metallic iridium forming a Schottky contact with an n-type semiconductor.

[0038] Further, metal iridium is added to metal iridium to form metal iridium-metal nickel-metal iridium; the thicknesses of each layer are respectively:

[0039] Metal iridium: 5-120 nm

[0040] Metal nickel: 1-40 nm

[0041] Metal iridium: 5-120 nm

[0042] The preparation process can adopt methods such as sputtering or electron beam evaporation, and the transparent electrode can be used to form an ohmic contact on the semiconductor material.

[0043] In order to achieve the above object, taking the electron beam evaporation method as an example, the present invention can be prepared by the following steps:

[0044] A. The mask layer is prepared by photolithography technology, so that the part of the semiconductor surface and the metal electrode is exposed, and the rest is cove...

Embodiment 2

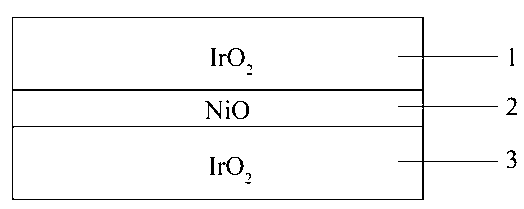

[0050] like figure 2 As shown, the present invention discloses an iridium oxide that forms an ohmic contact with a p-type semiconductor.

[0051] Further, nickel oxide is added to iridium oxide to form iridium oxide-nickel oxide-iridium oxide. The thickness of each layer is:

[0052] Iridium Oxide: 5-120 nm

[0054] Iridium Oxide: 5-120 nm

[0055] The preparation process may adopt methods such as sputtering or electron beam evaporation, and then oxidize in an oxygen or air atmosphere. The transparent electrode can be used to form a Schottky contact on the semiconductor material.

[0056] Taking the electron beam evaporation method as an example, the preparation method is similar to that of Example 1, steps A, B, and C are the same, and in step D, the alloy is carried out in oxygen or air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com