Shear wall connection structure and construction process thereof

A technology for connecting structures and construction techniques, applied in the direction of structural elements, walls, building components, etc., can solve the problems of rough end walls, poor connection effect, and small contact area of shear walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

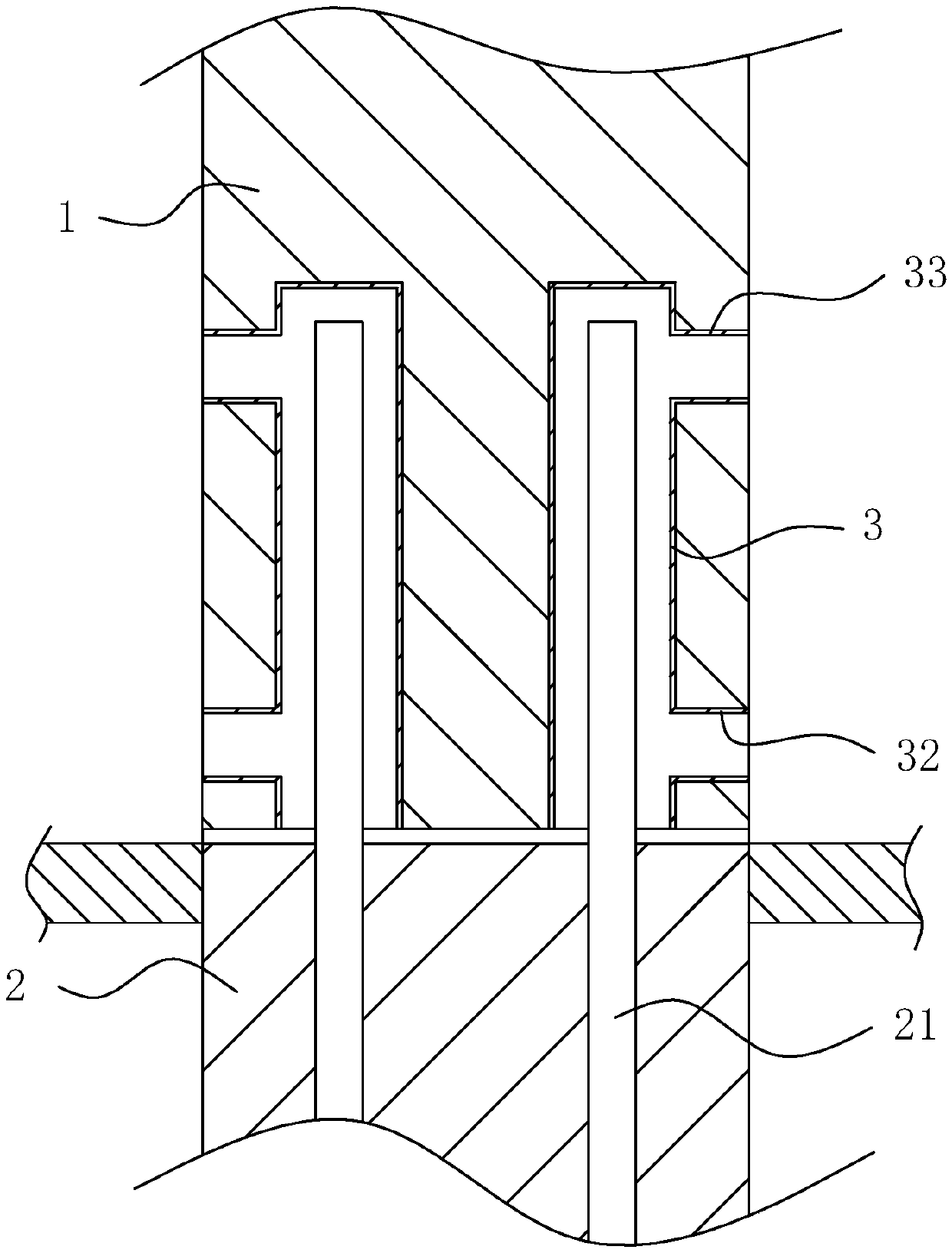

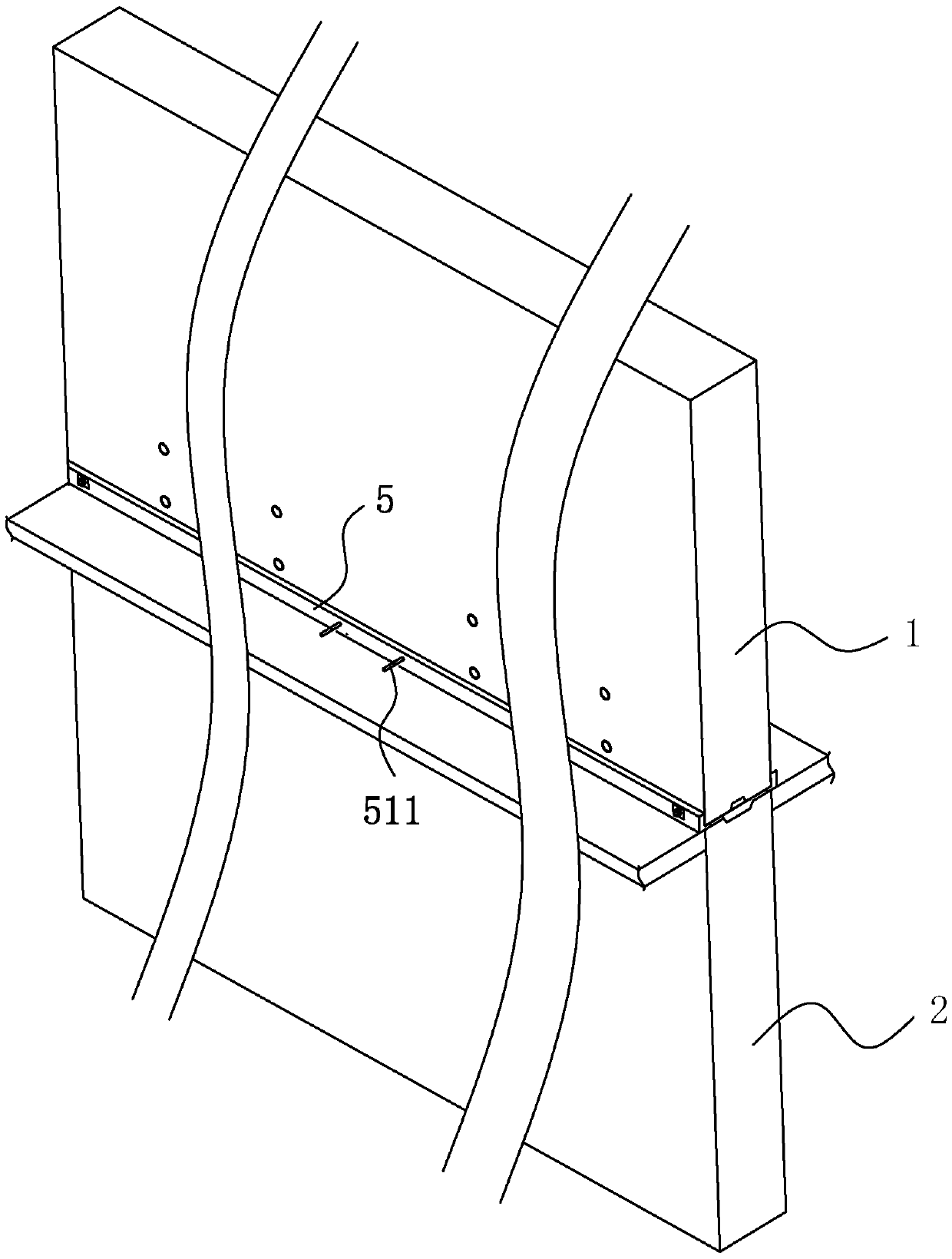

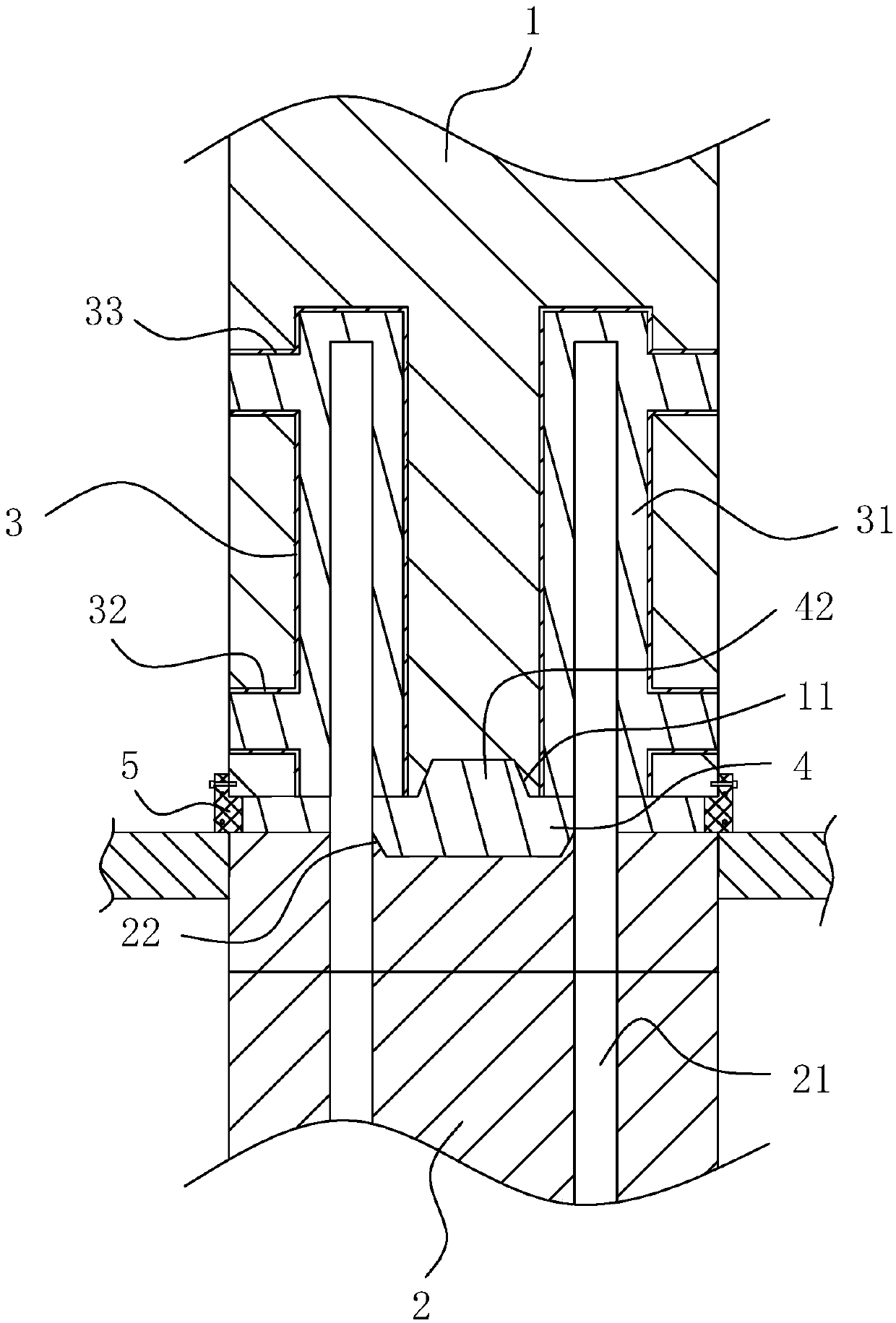

[0042] A shear wall connection structure, refer to figure 2 with image 3 , which includes an upper wall 1 and a lower wall 2, the lower end wall of the upper wall 1 is provided with a number of grouting sleeves 3 on both sides thereof, and the wall of the grouting sleeve 3 is connected with a wall extending to the upper wall 1 External grouting pipe 32 and grouting pipe 33, the grouting pipe 32 is positioned at the lower end of the grouting sleeve 3, and is used for injecting concrete in the grouting sleeve 3; The grouting pipe 33 is positioned at the upper end of the grouting sleeve 3, when draining When concrete is discharged in the grout pipe 33, it means that the inside of the grouting sleeve 3 is full of concrete.

[0043] refer to image 3 , the interior of the lower wall 2 is embedded with several butt reinforcing bars 21, and the upper ends of the butt reinforcing bars 21 extend upwards to the outside of the upper end wall of the lower wall 2; the upper ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com