Helicopter hub magnetorheological shimmy damper

A technology of magneto-rheological and shimmy dampers, which is applied in the direction of rotorcraft, aircraft, motor vehicles, etc., can solve the problems of lack of adaptability, oil leakage of shimmy dampers, etc., and achieve strong adaptability, easy installation, and avoid power transmission Effects of wiring problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

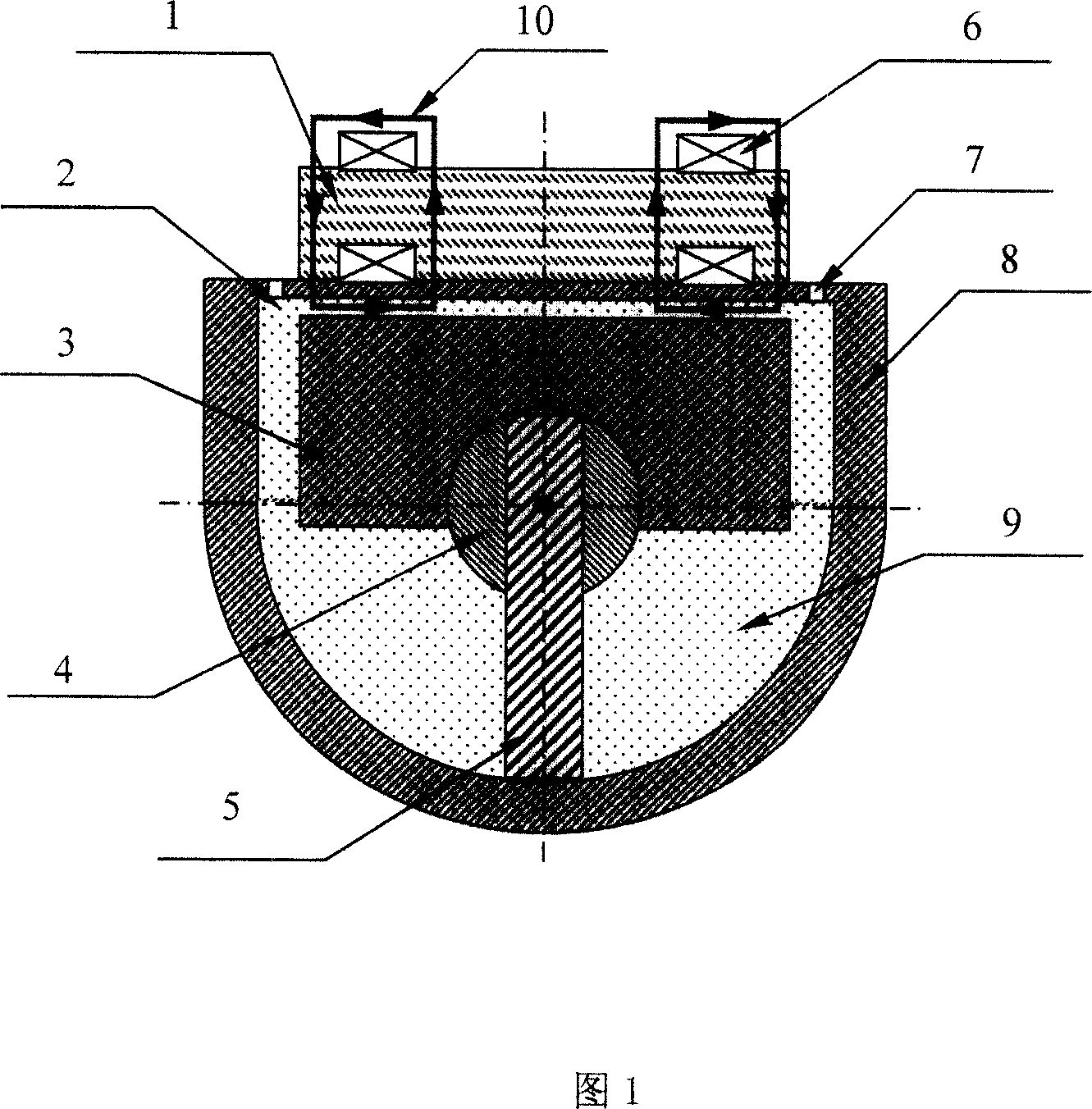

[0009] Figure 1 is a schematic diagram of the structure of the magneto-rheological damper for the helicopter hub. Describe concrete structure and implementation steps of the present invention according to accompanying drawing:

[0010] The specific structure of the present invention is that the excitation coil 6 is installed outside the damper, and the magneto-rheological fluid 9 is injected into the inner chamber of the liquid reservoir through the two liquid injection holes 7 of the liquid storage chamber. The cavity wall, the upper end cover and the armature 3 of the semicircular liquid reservoir 8 form the magnetorheological fluid return channel 2 . The reciprocating rotary piston 5 is connected with the rotary shaft 4 mounted on the armature 3 and reciprocates together, and the magnetorheological fluid 9 reciprocates in the magnetorheological fluid return channel 2 along with the reciprocating rotary piston 5 . When the excitation coil 6 is energized, a magnetic field is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com