Three-directional shafting dynamic vibration absorber and design method thereof

A dynamic vibration absorber and shafting technology, which is applied in the field of vibration absorption, can solve the problems of high manufacturing cost, complex structure, and need for additional energy, and achieve the effect of simple structure and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in detail in conjunction with the accompanying drawings.

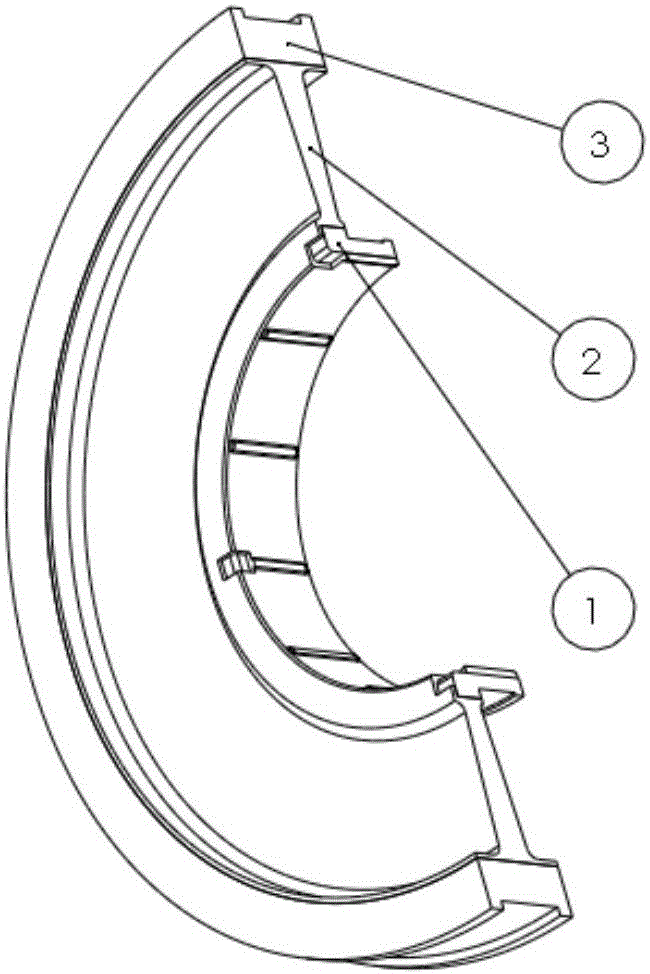

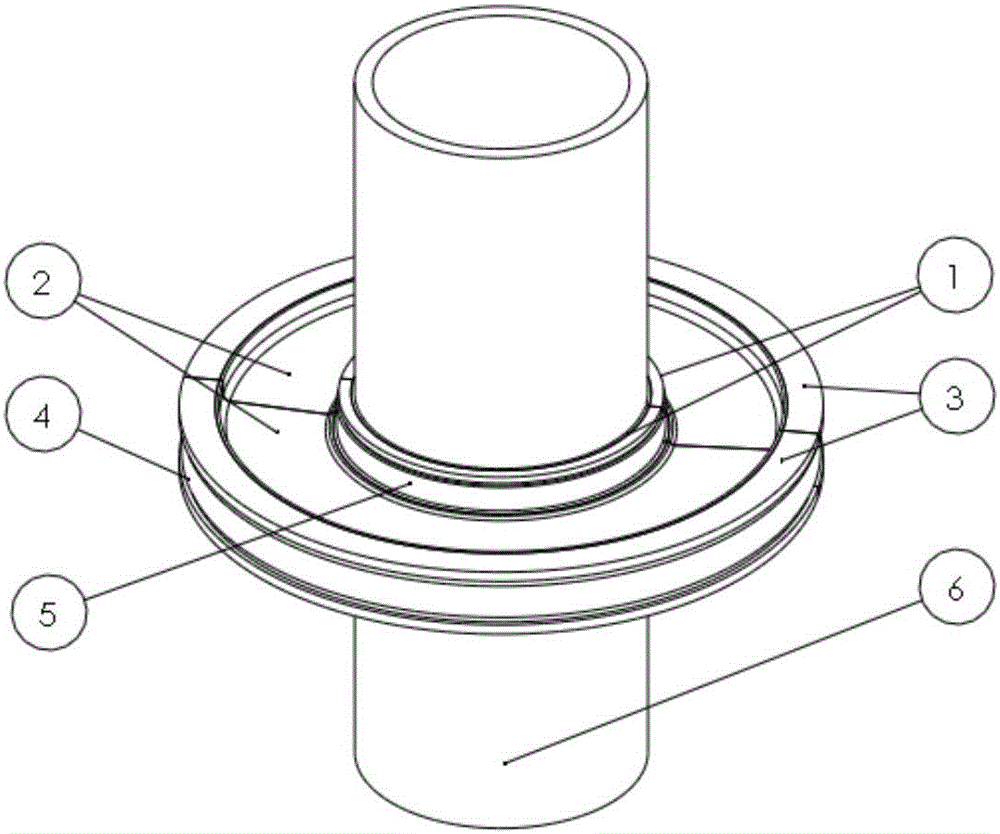

[0021] Such as figure 1 , figure 2 As shown, the three-way shafting dynamic vibration absorber of the present invention is composed of an annular mass 3, a rubber element 2, an installation bushing 1, an outer clamp 4 and an inner clamp 5, and is characterized in that the installation sleeve 1 is fastened on the shaft 6 surface, the outer side of the installation bushing 1 and the inner side of the annular mass 3 are vulcanized and connected by the rubber element 2; and the installation bushing 1 are provided with card slots, the outer clamp 4 is clamped on the slots of the annular masses 3 of the two semicircular rings, and the annular masses 3 of the two semicircular rings are butted into a ring, and the inner clamp The hoop 5 is clamped on the draw-in grooves of the mounting bushes 1 of the two semicircular rings, and the mounting bushings 1 of the two semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com