Bar mortice-tenon block assembling wall and construction method

An assembled and mortise-and-mortise technology, which is applied to walls, building components, buildings, etc., can solve the problems of complicated construction steps and increase the labor skills of workers, and achieve neat and beautiful appearance, open construction work surface and good sound insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

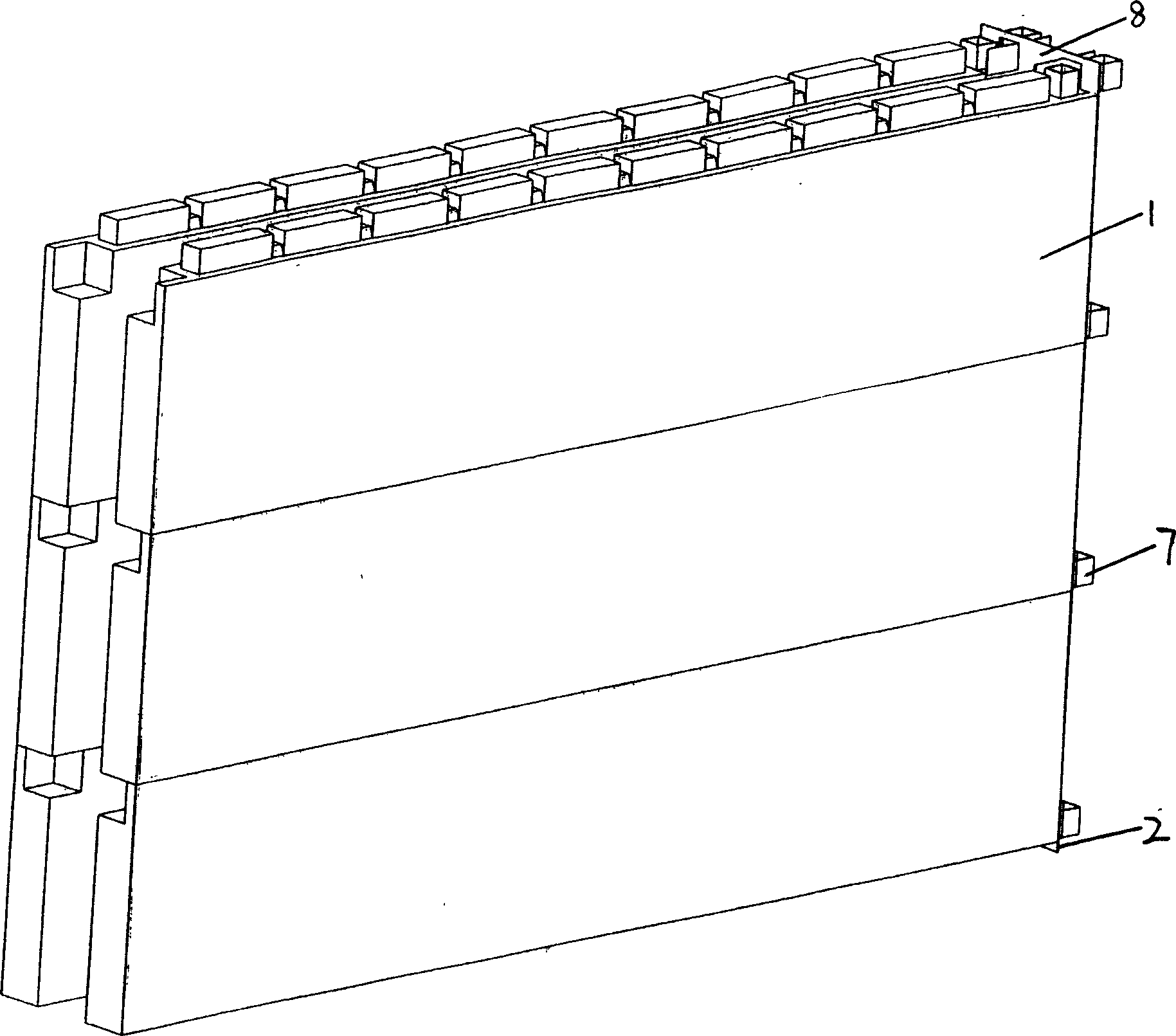

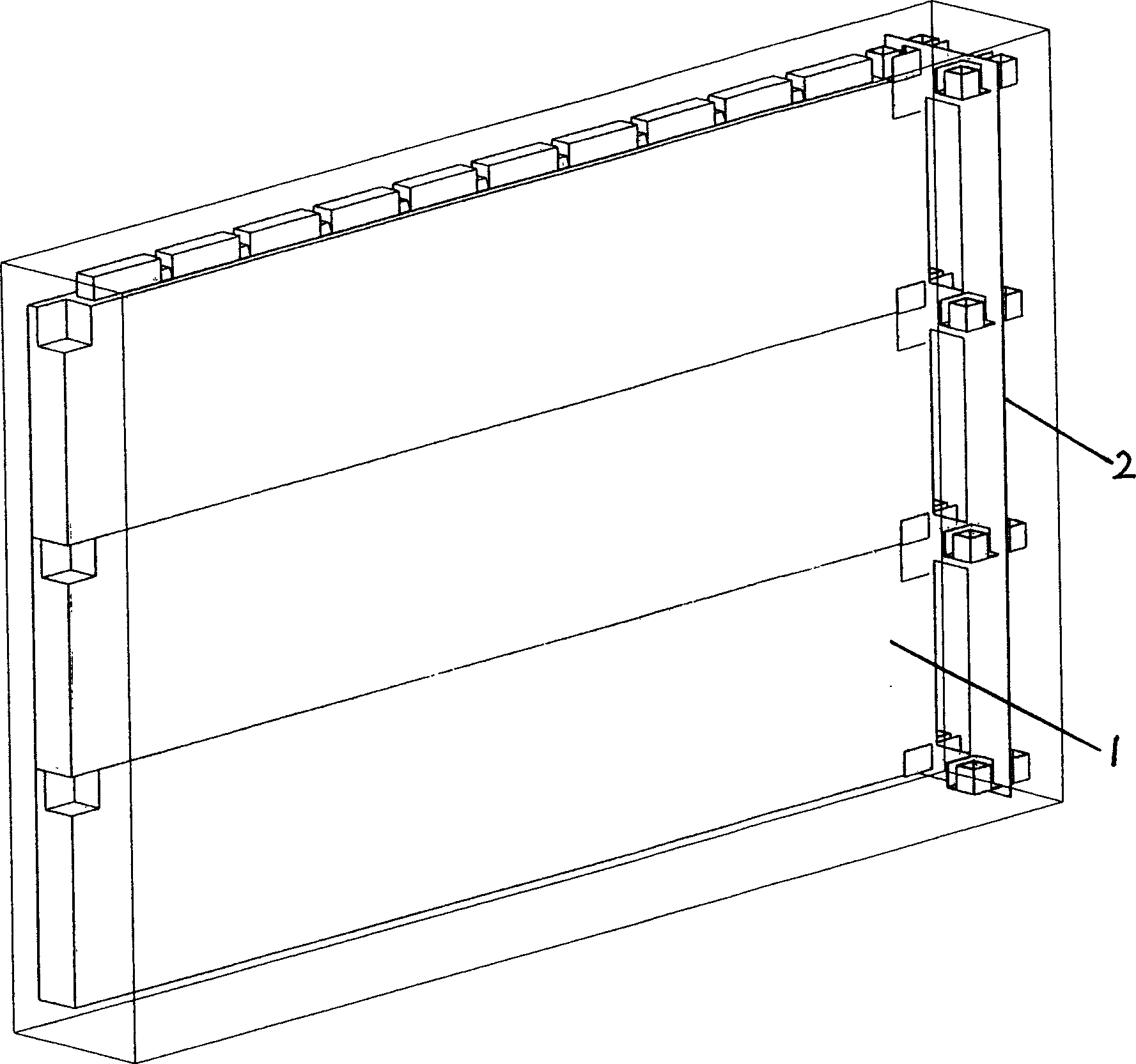

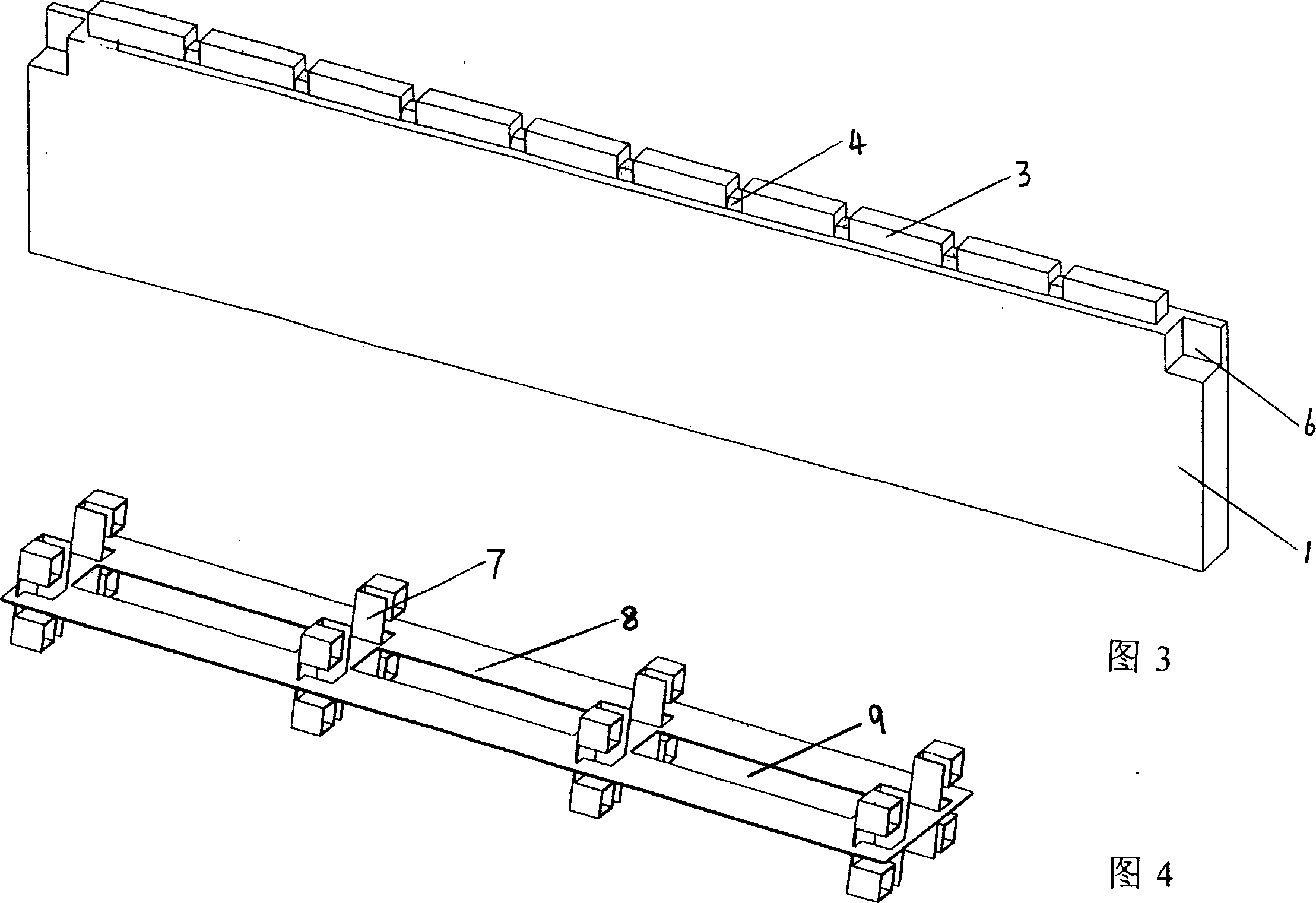

[0016] The overall combined structure of the wall body of the present invention, such as figure 1 As shown, it is assembled by a strip-shaped mortise-and-tenon block 1 and a tenon-and-tenon joint 2. The groove 6 of the strip-shaped tenon-tenon block 1 is inserted into the tenon 7 of the joint 2, and the joint 2 It is fixed on the upper and lower floors, and there is an interlayer of thermal insulation material or sound insulation material between the two-layer strip-shaped mortise and tenon blocks, and the gaps on the mortise and tenon occlusal surfaces of the strip-shaped mortise and tenon blocks are coated with closed glue. The structure of strip-shaped mortise and tenon block 1 is shown in Figure 3 and Figure 5. It is made into a cuboid, and one side of the long side has a strip-shaped tenon block 3 and tenon block 4, and the other side is opened on the tenon block 4. Tenon block groove 5 is arranged, and the position corresponding to bar-shaped tenon block 3 is made hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com