Composite nanofiber diaphragm for electrochemical element, preparation method and energy storage device

A technology of composite nanofibers and electrochemical components, which is applied in the direction of electrical components, battery pack components, circuits, etc. Solve the problems of poor wettability and liquid absorption ability, and achieve the effects of simple manufacturing process, prevention of fire and combustion, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Cellulose nanofibers, polypropylene fibers (low-melting point polymer nanofibers), and aramid fibers (flame-retardant materials) separated from nanometer-sized wood materials are dropped into dispersant deionized water by mass ratio of 75%, 20%, and 5%. , and then prepare the slurry by high-speed mechanical stirring to make the solution uniform as a whole, add additive acetic acid to the slurry, and the mass content of acetic acid accounts for 0.1% of the absolute dry weight of nanocellulose fibers. Add water to dilute the slurry to a mass concentration of 0.01%. The diluted slurry is dehydrated and formed on the Internet; pressed and dried; hot-rolled at a forming temperature of 120°C and a line pressure of 120kg / cm. Rolling, rewinding, cutting and packaging to prepare composite nanofiber separators for batteries.

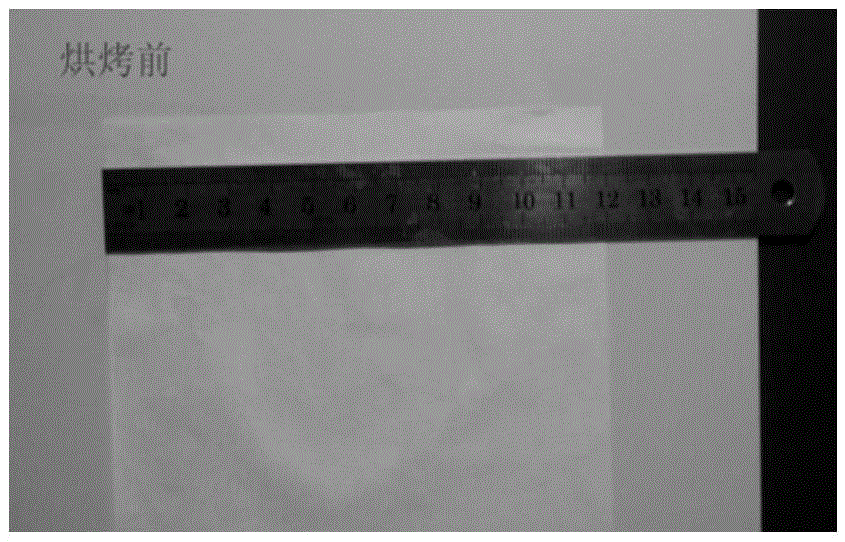

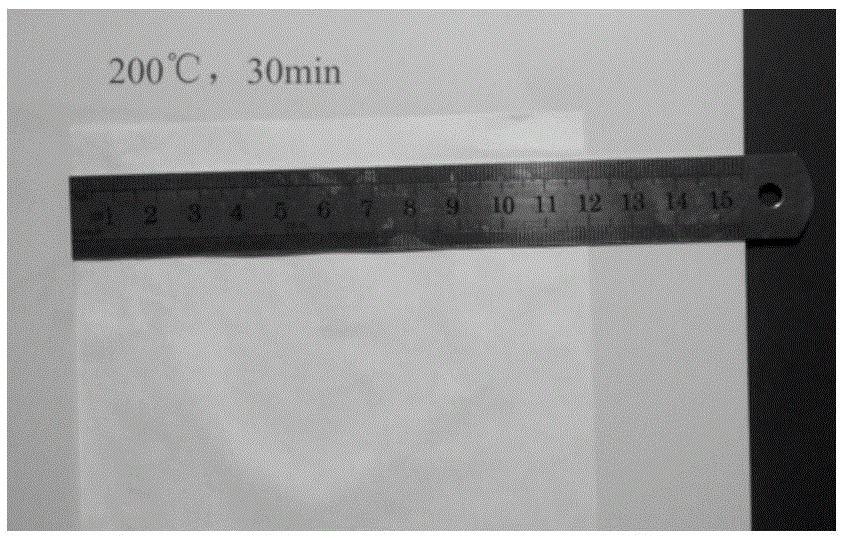

[0040] The thickness of the composite nanofiber separator is 20 μm, the porosity is 45%, and the LOI is 30%; the dimensional shrinkage rate is 0.05% at 200...

Embodiment 2

[0042] Seaweed cellulose nanofibers, polyethylene-vinyl acetate copolymer (low melting point polymer nanofibers), phenolic fibers (flame retardant materials) are dropped into dispersant isopropanol by mass ratio of 20%, 65%, and 15%, And then the slurry is prepared by high-speed mechanical stirring to make the solution uniform as a whole, and the additive hydroxymethyl cellulose is added to the slurry, and the mass content of hydroxymethyl cellulose accounts for 10% of the absolute dry weight of the nanocellulose fibers. Add water to dilute the slurry to a mass concentration of 0.01%. The diluted slurry is dehydrated and formed on the Internet; pressed and dried; hot-rolled at a forming temperature of 110°C and a line pressure of 120kg / cm. Rolling, rewinding, cutting and packaging to prepare composite nanofiber separators for batteries.

[0043] The thickness of the composite nanofiber separator is 50 μm, the porosity is 40%, and the LOI is 65%; the dimensional shrinkage rate ...

Embodiment 3

[0045] A mixture of bacterial cellulose nanofibers, polyvinyl alcohol (low-melting point polymer nanofibers), tris(2,3-dibromopropyl) isocyanurate and ammonium cyanide (flame retardant) obtained by culturing bacterial strains Material) by mass ratio 75%, 20%, 5% into the dispersant deionized water, and then by high-speed mechanical stirring to make the solution reach the uniformity of the whole to prepare the slurry, add the additive chitosan, chitosan The mass content accounts for 10% of the absolute dry weight of the cellulose nanometer cellulose fiber. Add alcohol-water mixture to dilute the slurry to a mass concentration of 0.05%, and dehydrate the diluted slurry on the Internet; press and dry; hot-roll forming at a molding temperature of 110°C and a linear pressure of 120kg / cm , and then through paper rolling, rewinding, slitting and packaging, the composite nanofiber separator for batteries is obtained.

[0046] The thickness of the composite nanofiber separator is 80 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com