Halogen-free flame retardant polylactic acid toughening modification composite material and preparing method thereof

A technology of toughening modified and composite materials, which is applied in the field of halogen-free flame-retardant polylactic acid toughened and modified composite materials and its preparation, which can solve the problems of flammability and poor impact performance, and achieve excellent elongation at break and toughness , the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

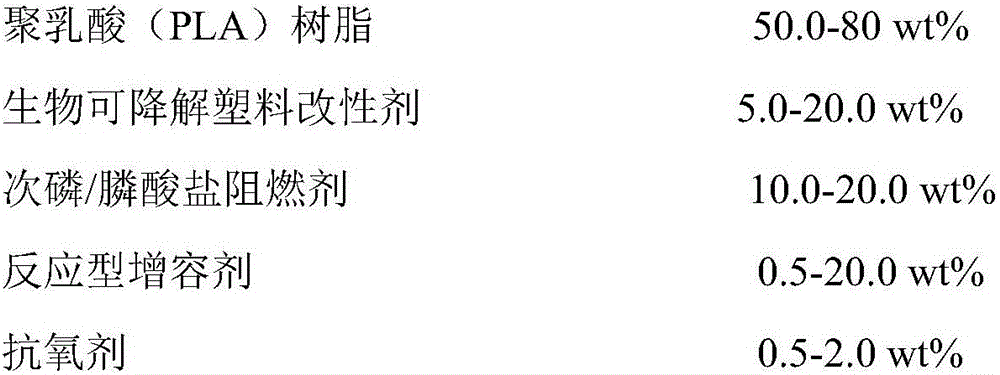

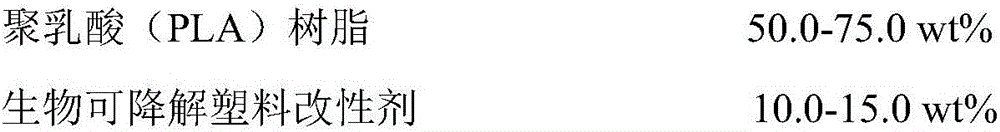

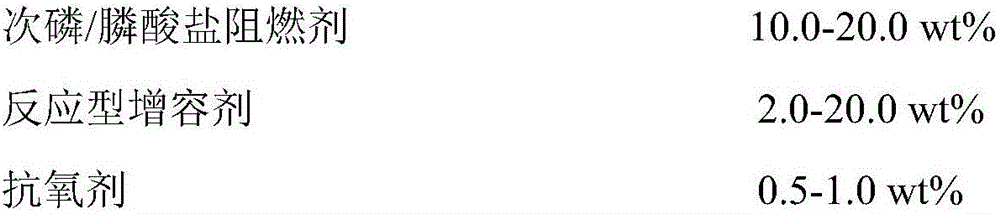

Method used

Image

Examples

Embodiment 1

[0026] 15.0wt% aluminum hypophosphite, 10.0wt% polycaprolactone, 0.5wt% butyl acrylate-methyl methacrylate-glycidyl methacrylate, 0.5wt% antioxidant tetrakis[β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (1010) is put into the high-speed mixer and mixed evenly, then after mixing evenly with 74.0wt% polylactic acid resin, add the twin-screw extruder , melt extrusion at 180-210°C, rotate at 100 rpm, and cool to granulate. The LOI of the obtained halogen-free flame-retardant polylactic acid composite material is 28.5, and the vertical combustion rating is V-0. The notched impact strength of flame-retardant polylactic acid toughened and modified composites is 7.0kJ / m 2 , the tensile strength is 45.6MPa, the elongation at break is 32%, the flexural strength is 68.5MPa, and the flexural modulus is 2.4GPa.

Embodiment 2

[0028] 17.0wt% aluminum diethylphosphinate, 10.0wt% polyvinyl alcohol, 2.5wt% epoxidized ethylene propylene rubber, 0.5wt% antioxidant tris(2,4-di-tert-butylphenyl ) ester (168) is put into a high-speed mixer and mixed evenly, then mixed evenly with 70.0wt% polylactic acid resin, then added to a twin-screw extruder, and melted and extruded at 180-210°C at a speed of 50 rpm. And cooling granulation. The LOI of the obtained halogen-free flame-retardant polylactic acid composite material is 29.0, and the vertical combustion rating is V-0. The notched impact strength of flame-retardant polylactic acid toughened modified composite is 8.5kJ / m 2 , the tensile strength is 42.3MPa, the elongation at break is 41%, the flexural strength is 66.3MPa, and the flexural modulus is 2.2GPa.

Embodiment 3

[0030] 12.5wt% aluminum hypophosphite, 15.0wt% polyadipate / butylene terephthalate, 5.0wt% ethylene-acrylate-glycidyl methacrylate terpolymer, 0.5wt% antioxidant 1010 is mixed evenly in a high-speed mixer, then mixed evenly with 67.0wt% polylactic acid resin, then added to a twin-screw extruder at a speed of 50 rpm, melted and extruded at 180-210°C, and cooled to pelletize. The LOI of the obtained halogen-free flame-retardant polylactic acid composite material is 27.5, and the vertical combustion rating is V-0. The notched impact strength of flame-retardant polylactic acid toughened modified composite is 9.6kJ / m 2 , the tensile strength is 41.2MPa, the elongation at break is 50%, the flexural strength is 62.0MPa, and the flexural modulus is 2.1GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com