Low smoke zero halogen flame-retardant mould shrinkage sleeve and preparation method as well as application thereof

A shrinking, linear low-density technology, which is applied in the field of low-smoke, halogen-free flame-retardant molded shrink sleeves and its preparation, can solve the problems of low cost performance, limited flame-retardant effect, and large smoke generation, and meets low equipment requirements. , small amount of smoke, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

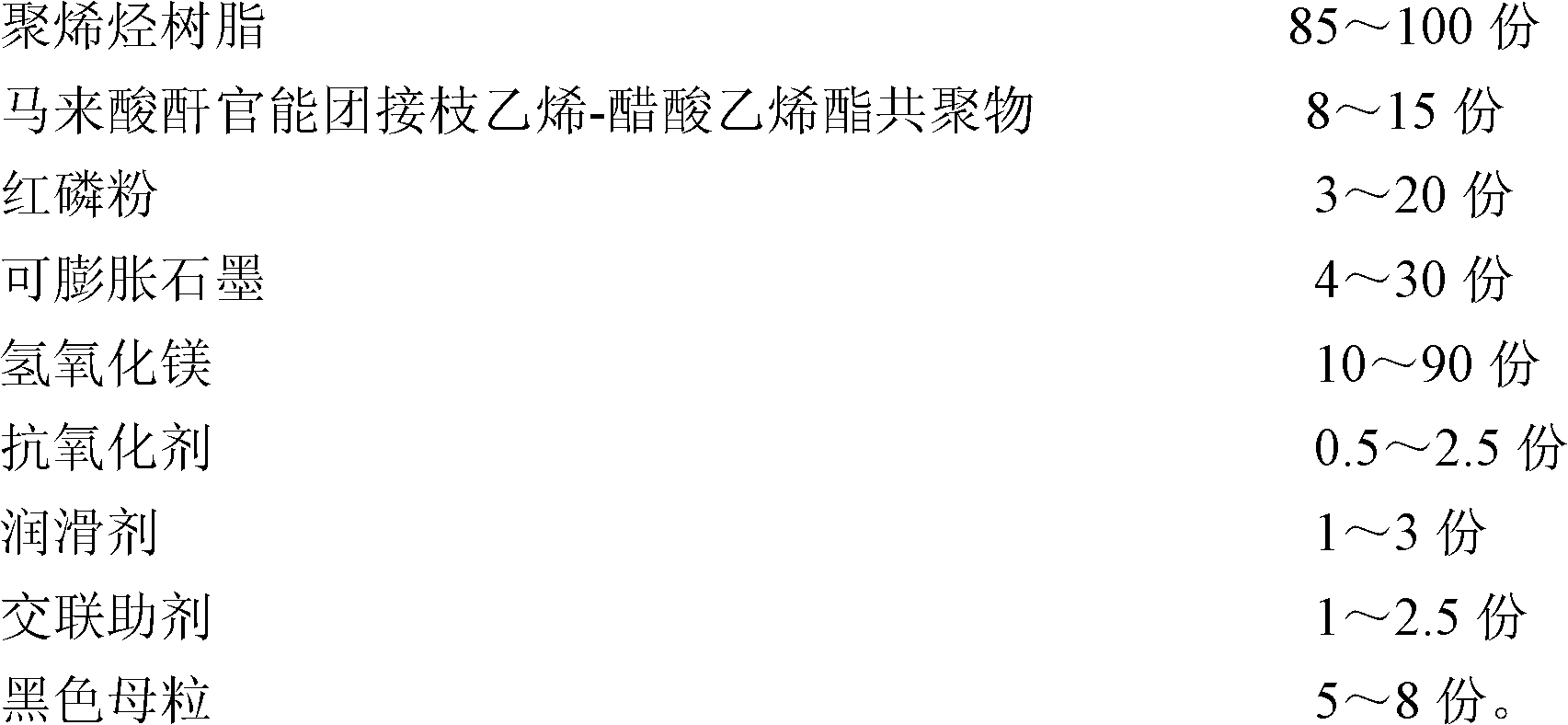

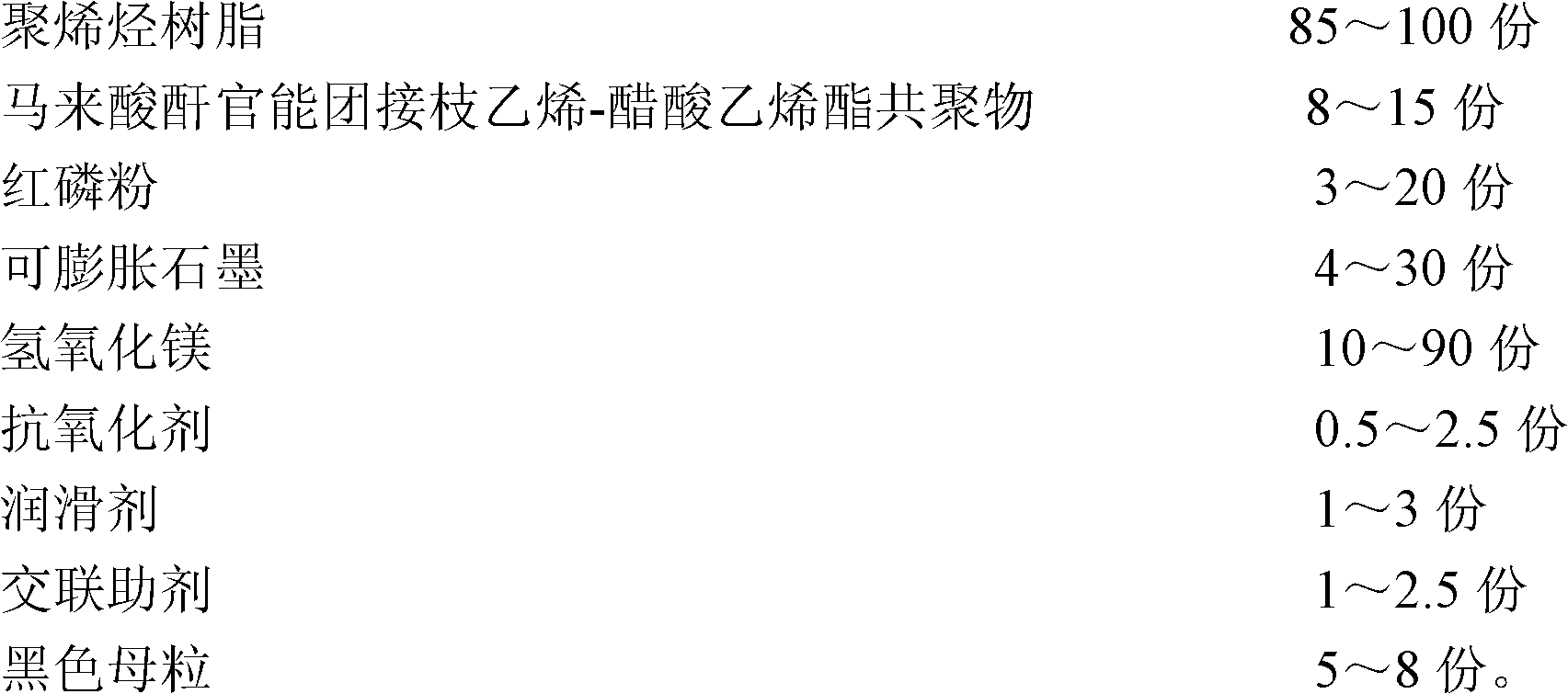

Method used

Image

Examples

Embodiment 1

[0044] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVatane 2803) 80kg, linear low density polyethylene ( LLDPE, Saudi Basic Industries Corporation, grade 218-W) 20kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (grafting rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Materials Co., Ltd., the brand is JCP-851) 10kg, red phosphorus powder 10kg (Qingyuan Yicheng Flame Retardant Material Co., Ltd.), expandable graphite (average particle size is 400 mesh, expansion rate is 150ml / g, Qingdao Tianhe Graphite Co., Ltd. company) 20kg, magnesium hydroxide (white powder, no mechanical impurities, MgO content > 67% by mass, average particle size less than 200nm, U.S. Albemarle, brand H5) 50kg, 0.5kg antioxidant 1010, thiodisulfide Two (octadecyl) propionate (DSTP) 2kg, zinc stearate (ZnSt) 3kg, trimethylolpropane triacrylate (...

Embodiment 2

[0047] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 45kg, ethylene-vinyl acetate copolymer Material (EVA, the content of vinyl acetate accounts for 14% quality, and melt index is 3.5g / 10min, Japan's Mitsui Group, trade mark is P1405) 50kg, maleic anhydride functional group graft ethylene-vinyl acetate copolymer (Shanghai Jiuju Macromolecular Materials Co., Ltd., the trade mark is JCT-1C) (grafting rate is 1.0%, and melt index is 2.0g / 10min) 8kg, red phosphorus powder 11kg, expandable graphite (average particle diameter is 400 orders, expansion rate is 150ml / g, Qingdao City Tianhe Graphite Co., Ltd.) 17kg, magnesium hydroxide (white powder, no mechanical impurities, MgO content > 67% by mass, average particle diameter less than 200nm, U.S. Albemarle Company, the brand is H5) 40kg, 0.25kg antioxidant 1076, di(octadecyl)thiodipropionate (DSTP) 0.2...

Embodiment 3

[0050] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 60kg, ethylene-vinyl acetate copolymer Material (EVA, the content of vinyl acetate accounts for 14% quality, and melt index is 3.5g / 10min, Japan's Mitsui Group, trade mark is P1405) 25kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (Shanghai Jiuju Polymer Material Co., Ltd., the brand is JCT-1C) (grafting rate is 1.0%, melt index is 2.0g / 10min) 15kg, red phosphorus powder (Qingyuan Yicheng Flame Retardant Material Co., Ltd.) 18kg, expandable graphite ( The average particle size is 400 mesh, the expansion rate is 150ml / g, the carbon content is 90-99.9%, Qingdao Tianhe Graphite Co., Ltd.) 10kg, magnesium hydroxide (white powder, no mechanical impurities, MgO content > 67% by mass , the average particle size is less than 200nm, and the specific surface area is 4.0-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com