Halogen-free low-smoke flame-retardant polypropylene/polyamide composite material and preparation method

A low-smoke, flame-retardant, and composite material technology, applied in the field of polymer materials, can solve the problems of corrosive hydrogen chloride gas, high cost, and health hazards, and achieve the effects of low cost, simple manufacturing process, and excellent flame retardant performance

Inactive Publication Date: 2010-08-25

ANHUI KEJU NEW MATERIALS

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the release of toxic and corrosive hydrogen chloride gas during the burning process of PVC wire and cable materials, it seriously endangers people's health

GE has since launched a wire and cable material that uses flexible Noryl resin to replace PVC. However, the material is expensive. Therefore, it is particularly important to develop a new type of low-cost, halogen-free, low-smoke, flame-retardant wire and cable composite material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

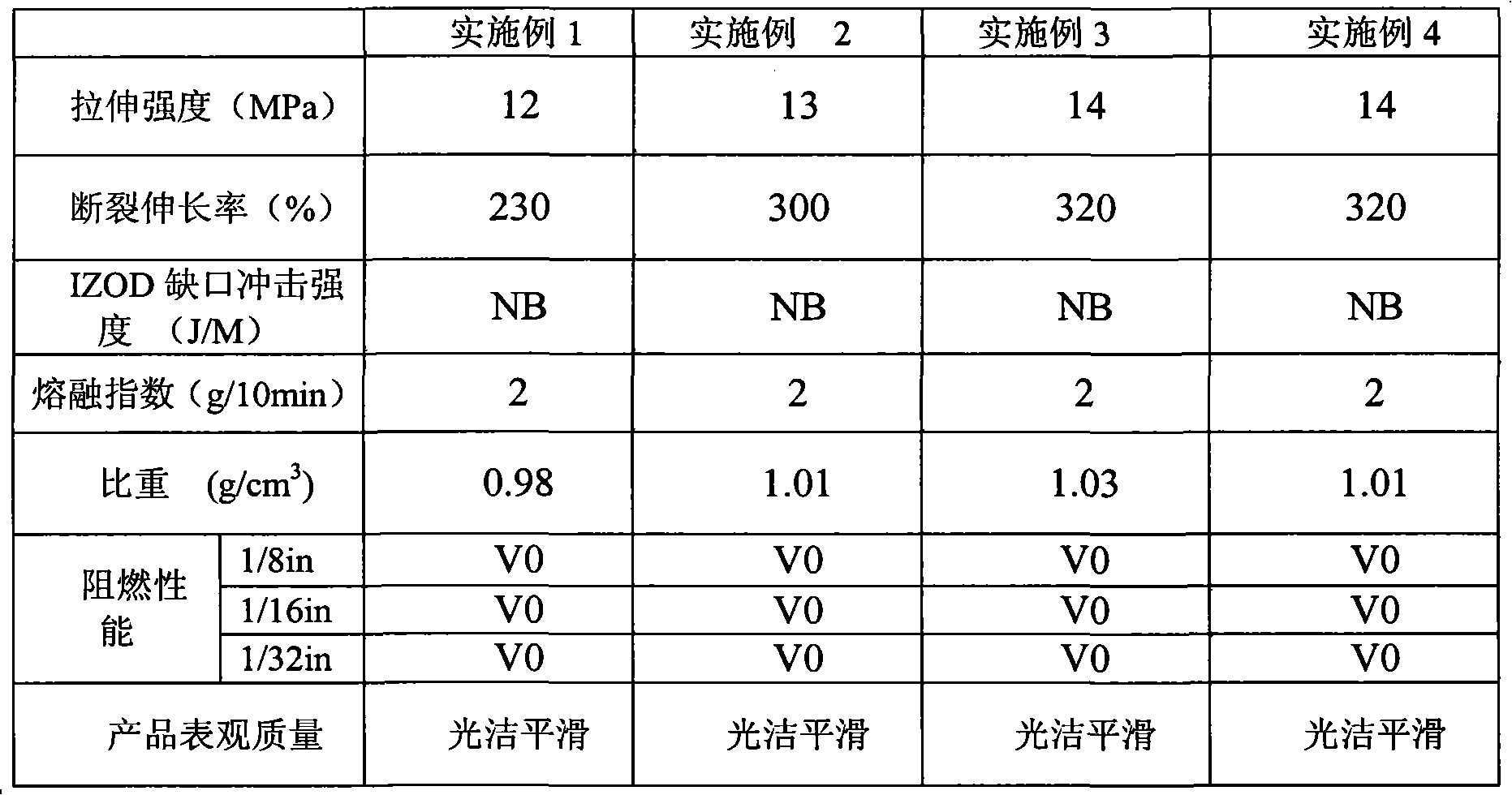

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a halogen-free low-smoke flame-retardant polypropylene / polyamide composite material, which is prepared by the following raw materials in parts by weight: 100 parts of polypropylene, 30-50 parts of polyamide, 20-50 parts of thermoplastic elastomer, 30-50 parts of halogen-free low-smoke flame-retardant agent, 10-20 parts of high molecular compatilizer, 1-5 parts of dispersing agent and 1-5 parts of antioxidant. After the raw materials are weighed according to the weight parts, the raw materials are evenly mixed and are fused and extruded through a double-screw extruder and are granulated. The method has the advantages that the process is simple, the cost is low, the weight of the obtained composite material is light, no halogen is contained and the smoke is low, the flame-retardant performance is good, the aging resistance is high and the surface is bright and smooth.

Description

technical field The invention belongs to the technical field of polymer materials, and more specifically relates to a halogen-free low-smoke flame-retardant polypropylene / polyamide composite material and a preparation method thereof. Background technique Plastic has many advantages such as easy processing, light weight, and corrosion resistance. It has been used in many fields instead of wood, stone, and steel, which greatly facilitates people's daily life. With the emergence and development of polymer materials, fire accidents are also increasing, and the flame-retardant technology of polymer materials has emerged as the times require. Polymer flame-retardant materials are mostly used for insulation and sheathing of wires and cables. Due to the lessons of cable fires, in the late 1980s, flame-retardant cables have become an inevitable trend in the development of cables, thus actively promoting the flame-retardant of polyvinyl chloride (PVC) materials and the development o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/14C08L77/02C08L23/00C08L83/04C08L51/06C08K5/523C08K3/32B29C47/92B29B9/06B29C48/405B29C48/92

CPCB29C48/92B29C2948/92704B29C48/04B29C2948/9259B29C2948/92885B29C2948/92895B29C48/405

Inventor 杨书涛

Owner ANHUI KEJU NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com