High-molecular flame-retardant foam material and preparation method thereof

A technology of foaming materials and polymers, which is applied in the field of preparation of polymer flame-retardant foaming materials, can solve the problems of poor flame-retardant effect, poor thermal insulation effect, and good thermal insulation effect, and achieve good thermal insulation effect and flame-retardant performance. Good, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

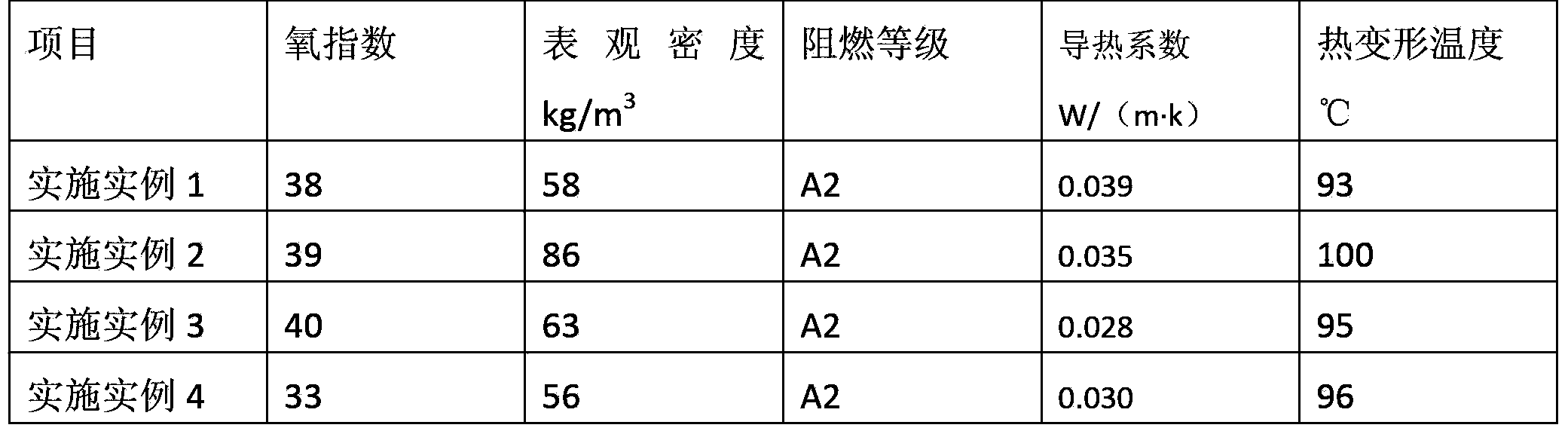

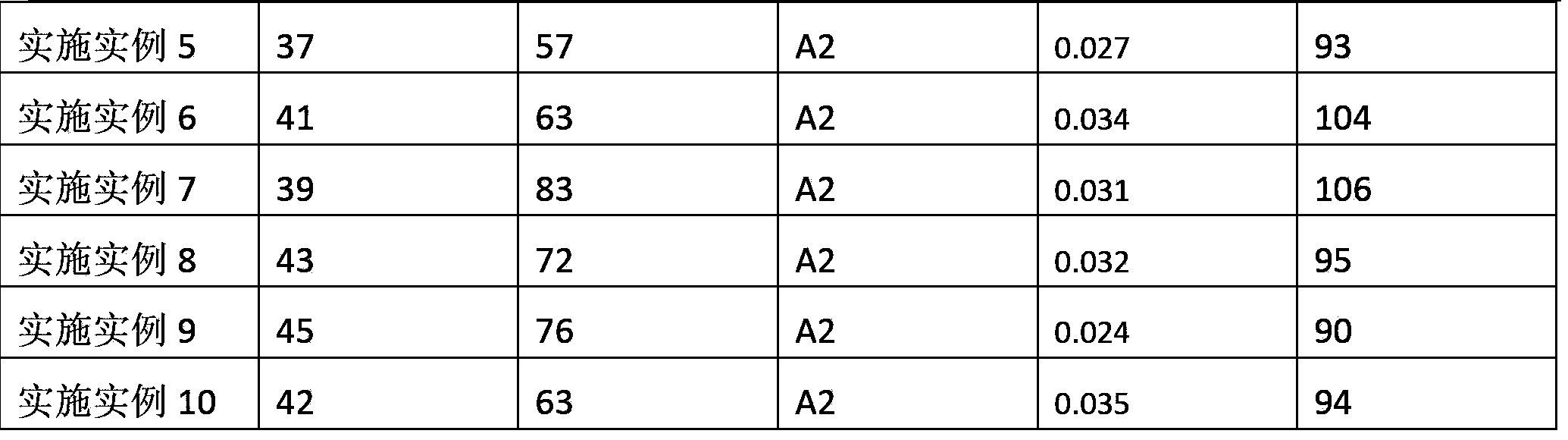

Embodiment 1

[0026] The urea-formaldehyde resin, magnesium oxide, and sorbitan monostearate in a weight ratio of 100:4:1 were mixed for 25 minutes at a stirring rate of 300 rpm at 40°C to prepare an organic flame-retardant adhesive. The organic flame-retardant adhesive and hydrochloric acid are stirred and mixed at 1000 rpm for 5 minutes and then added to the polystyrene foam particles with a particle size of 5 mm, and the polymer flame-retardant foam material is prepared by rapid hot pressing at 80°C. Polystyrene foam particles can be replaced by polypropylene foam particles.

Embodiment 2

[0028] Under the conditions of 80°C and 300 revolutions per minute, the epoxy resin, ammonium polyphosphate and sorbitan monostearate in a weight ratio of 80:2:1 were mixed for 20 minutes to prepare an organic flame-retardant adhesive . The organic flame-retardant adhesive and ethylenediamine were stirred and mixed at 500 rpm for 5 minutes, then added to the 0.5mm polystyrene foam particles, and the polymer flame-retardant hair was prepared by rapid hot pressing at 140°C. Bubble material.

Embodiment 3

[0030] The urea-formaldehyde resin, melamine and sorbitan monooleate in a weight ratio of 120:3:1 were mixed for 25 minutes under the condition of a stirring rate of 1200 rpm at 40°C to prepare an organic flame-retardant adhesive. The organic flame-retardant adhesive and hydrochloric acid are stirred and mixed at 1500 rpm for 5 minutes and then added to the polystyrene foam particles with a particle size of 1 mm, and the polymer flame-retardant foam material is prepared by rapid hot pressing at 180°C. Polystyrene foam particles can be replaced by polypropylene foam particles.

[0031] The preferred solution is that the flame retardant is two or more selected from the group consisting of aluminum oxide, magnesium oxide, zinc borate, melamine, ammonium polyphosphate, trimethyl phosphite and trimethyl phosphate A mixture of substances. Alumina, magnesia and ammonium polyphosphate are also mixed with good effects, especially when alumina or magnesia is mixed with trimethyl phosphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com