High-temperature-resistant neutron and Upsilon-ray shielding composite and preparation method thereof

A composite material, high temperature resistant technology, used in shielding, nuclear engineering, reactors, etc., can solve the problems of limiting the scope of use of shielding composite materials, no comprehensive consideration, etc., achieve good neutron and gamma ray shielding performance, and ensure stability. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

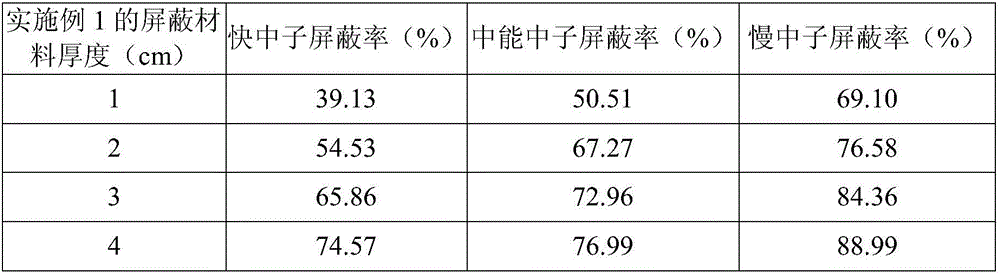

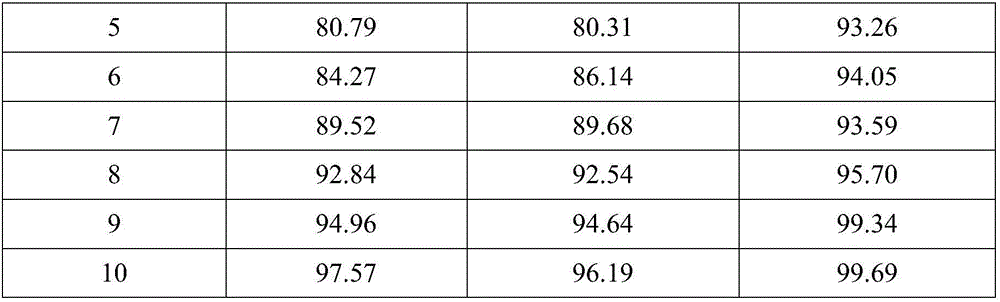

Embodiment 1

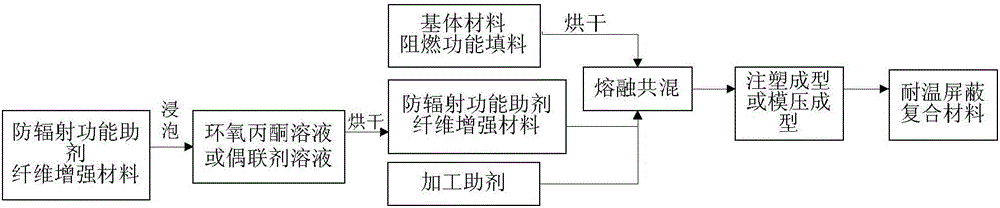

[0057] This embodiment provides a method for preparing a high temperature resistant neutron and gamma ray shielding composite material, the process flow chart is as follows figure 1 shown, from figure 1 It can be seen that the preparation method comprises the following specific steps;

[0058] (1) The high temperature resistant neutron and gamma ray shielding composite material is prepared by weight parts from the following components (as shown in Table 1):

[0059] Table 1

[0060] raw material name parts by mass Manufacturer Polyphenylene sulfide 100 copies Japan TOSOH company boron carbide 30 copies Ning'an Bohai Boron Carbide Co., Ltd. lead powder 300 copies Beijing Youxinglian Nonferrous Metals Co., Ltd. chopped glass fiber 40 copies Xuanyue Technology New Material Co., Ltd. magnesium hydroxide 80 copies Weifang Haililong Magnesium Industry Co., Ltd. epoxy resin 5 copies Bluestar New Materials Wuxi Resin...

Embodiment 2

[0068] This embodiment provides a method for preparing a high temperature resistant neutron and gamma ray shielding composite material, the process flow chart is as follows figure 1 shown, from figure 1 It can be seen that the preparation method comprises the following specific steps;

[0069] (1) The high-temperature-resistant neutron and gamma-ray shielding composite material is prepared by parts by weight from the following components (as shown in Table 2):

[0070] Table 2

[0071] raw material name parts by mass Manufacturer Polyphenylene sulfide 30 copies Sichuan Deyang Technology Co., Ltd. Polyetheretherketone 100 copies Jida Advanced Materials Co., Ltd. boron nitride 40 copies Liaoning Boda Technology Co., Ltd. Tungsten powder 200 copies Beijing Youxinglian Nonferrous Metals Co., Ltd. chopped carbon fiber 40 copies Carbon Composites Ltd. magnesium hydroxide 100 copies Weifang Haililong Magnesium Indus...

Embodiment 3

[0079] This embodiment provides a method for preparing a high temperature resistant neutron and gamma ray shielding composite material, the process flow chart is as follows figure 1 shown, from figure 1 It can be seen that the preparation method comprises the following specific steps;

[0080] (1) The high-temperature-resistant neutron and gamma-ray shielding composite material is prepared by parts by weight from the following components (as shown in Table 3):

[0081] table 3

[0082] raw material name parts by mass Manufacturer Polyethersulfone 40 copies Jida Advanced Materials Co., Ltd. Polyphenylene sulfide 60 copies Sichuan Deyang Technology Co., Ltd.; boron carbide 30 copies Ning'an Bohai Boron Carbide Co., Ltd. lead powder 300 copies Beijing Youxinglian Nonferrous Metals Co., Ltd. chopped glass fiber 40 copies Xuanyue Technology New Material Co., Ltd. magnesium hydroxide 80 copies Weifang Haililong Mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com