Entrained flow gasification stove, and gasification method

A gasifier and entrained bed technology, which is applied in the fields of combustible gas purification, granular/powder fuel gasification, combustible gas purification/reconstruction, etc., can solve the problem of high construction and maintenance costs, poor sealing performance of the furnace body, and inconvenient maintenance. and other problems, to achieve the effect of simple structure, easy maintenance and maintenance, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

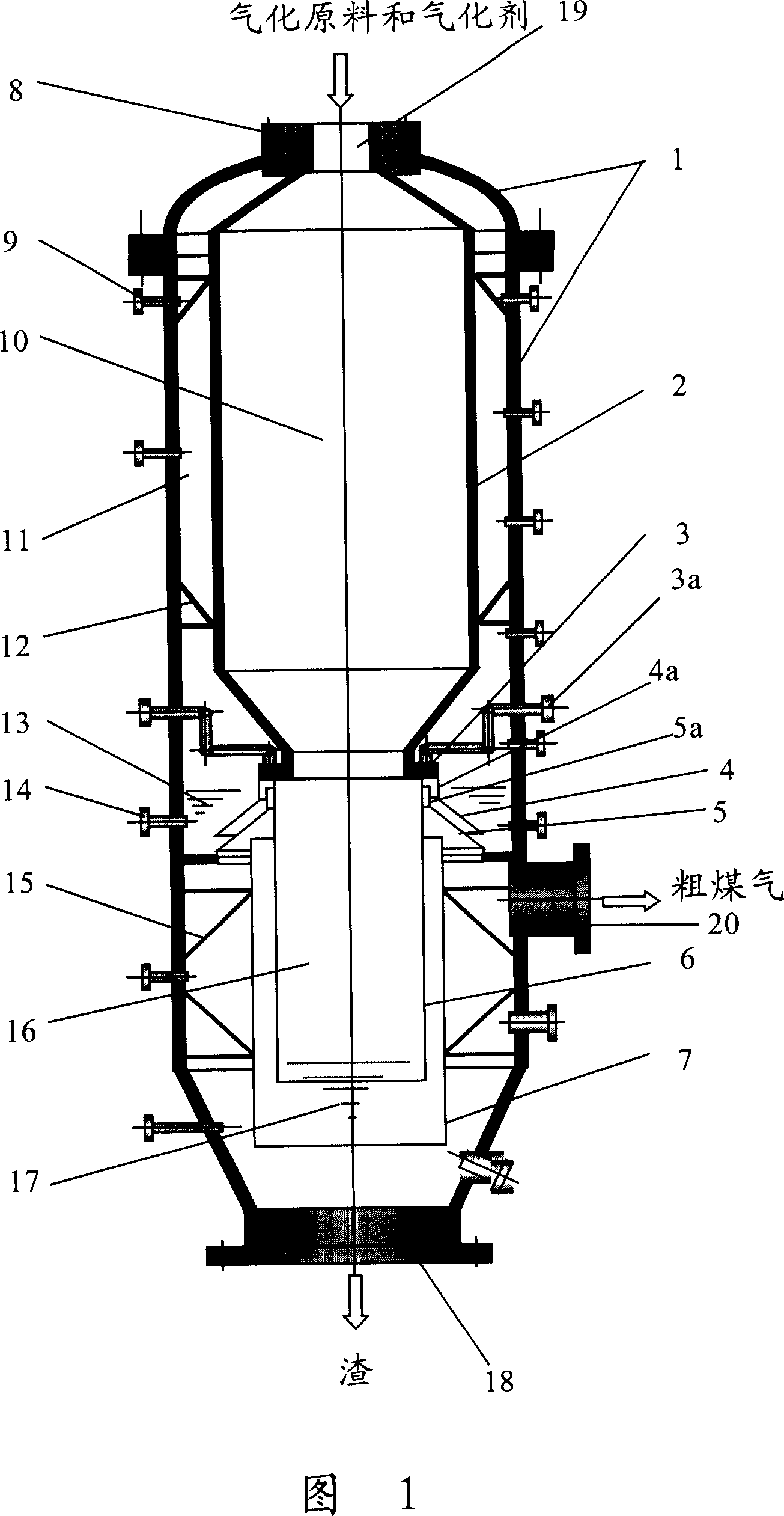

[0048] This example illustrates: the results obtained by using the entrained-flow gasifier of the present invention to carry out the gasification test.

[0049] The structure of the gasifier used in the test is shown in Figure 1, and its processing capacity is 48t / d. The main properties of the gasification raw materials used in the test are as follows:

[0050] Industrial Analysis: Weight %

[0051] Moisture Mar

Ash Aar

Volatile content Var

Total sulfur St.ar

0

16.18

43.15

2.85

[0052] Fusion characteristics of ash: ℃

[0053] Deformation temperature DT

Softening temperature ST

Flow temperature FT

1080

1150

1200

[0054] Main physical characteristics:

[0055] Flash point

℃

Softening Point

℃

Viscosity at 250°C

mpa.s

Viscosity at 300°C

mpa.s

290

140

1600

220

[0056] Th...

Embodiment 2

[0072] This example illustrates: the results obtained by using the entrained-flow gasifier of the present invention to carry out the gasification test.

[0073] The structure of the gasifier used in the test is shown in Figure 1, and its processing capacity is 48t / d. The gasification raw material used in the test is a kind of bituminous dry coal powder, its main properties are as follows:

[0074] Industrial Analysis: Weight %

[0075] Moisture Mad

Ash Aad

Volatile matter Vad

Total sulfur St.ad

5.6

5.36

34.73

0.4

[0076] Fusion characteristics of ash: ℃

[0077] Deformation temperature DT

Softening temperature ST

Flow temperature FT

1070

1150

1220

[0078] Other features:

[0079] high calorific value

Mj / kg

Grindability index

HGI

Reactivity at 1100°C

(α value)%

Coal particle size

%(<0.076mm)

28.2

65 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com