Method for constructing mining impact-resisting sealed wall

A construction method and airtight wall technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve problems affecting daily ventilation work, mine safety production, and thin airtight thickness, so as to achieve low labor intensity for workers and save manpower , Strong impact resistance and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

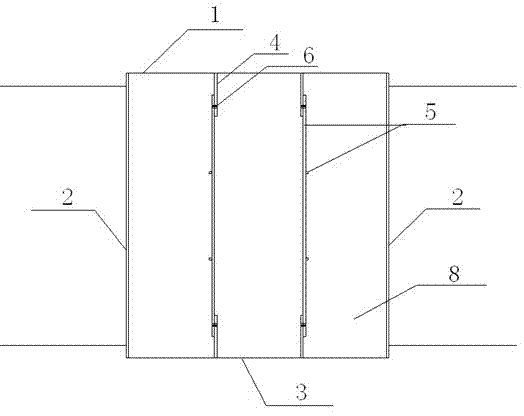

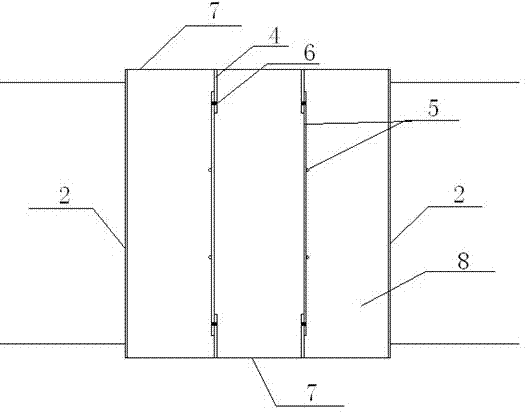

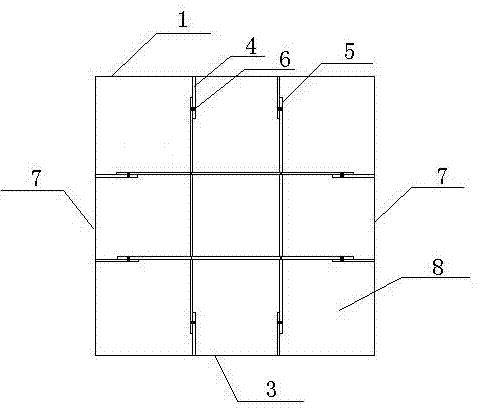

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Combine now figure 1 , figure 2 , image 3 , Figure 4 As an example: first, at the place where a closed wall needs to be built, the top plate 1, the bottom plate 3 and the two roadway walls 7 are cut, and then the wooden wall 2 is built behind the construction roadway, covered with plastic film, and the roadway is closed to prevent slurry leakage. The construction site is selected in a roadway with a certain inclination angle and an inclination; the depth of the cut is 300-500cm, and the plank wall 2 is 20-30cm wide and 2-3cm thick red pine nails.

[0024] Four anchor rods 4 are placed at the top plate 1, the bottom plate 3, and the two roadway walls 7 in the middle of the construction airtight wall, which are square, such as Figure 4 As shown, do bolt hole 9 on the bolt, the bolt 4 of top plate 1 and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com