Water-based rust inhibitor for steel protection, and preparation method and application thereof

A water-based rust inhibitor and rust inhibitor technology, applied in the field of iron and steel rust prevention, can solve the problems of unenvironmental protection and poor rust prevention effect of rust inhibitor, and achieve the effect of ensuring rust prevention effect and safety guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

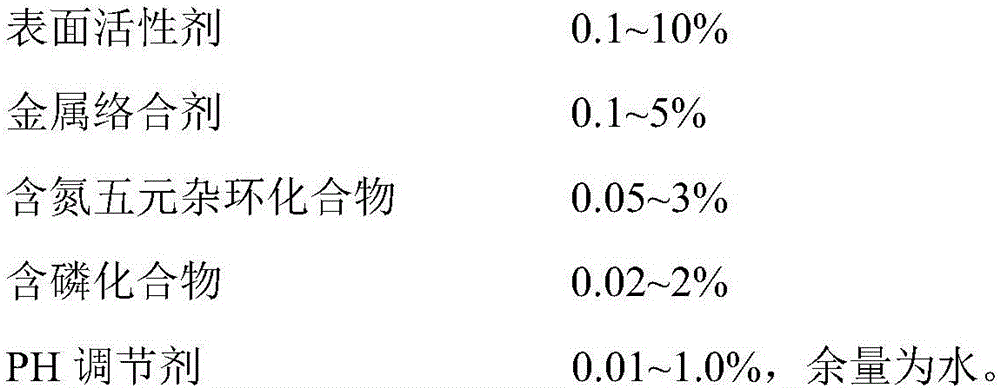

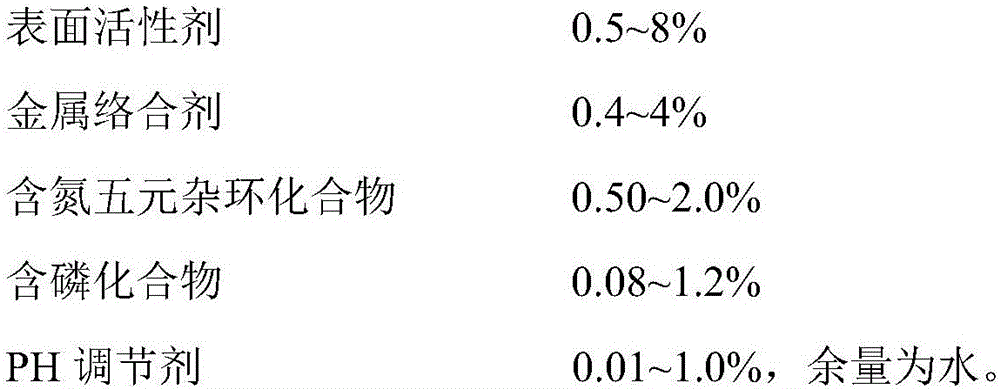

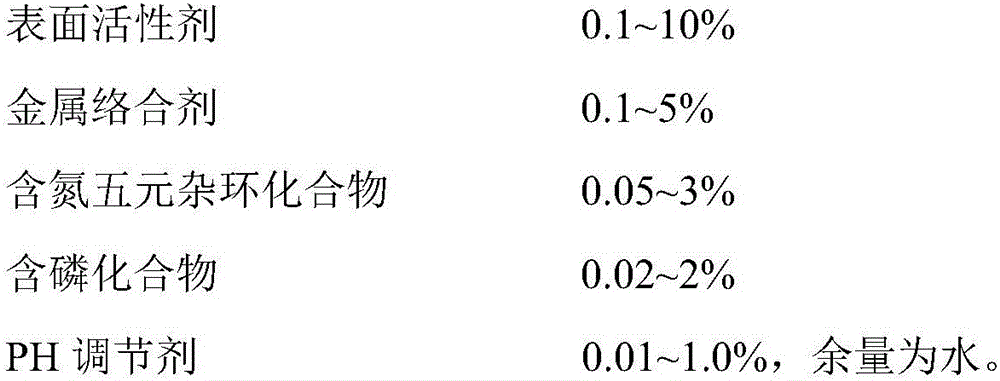

Method used

Image

Examples

Embodiment 1

[0042] Add the following substances to 600 mL of ionized water: 2 g of ethanolamine surfactant, 5 g of trihydroxypropyl hydroxyethyl ethylenediamine, 1.0 g of 2-methylimidazole, 0.5 g of sodium dihydrogen phosphate, stir after mixing, and then add water to 1L, and add appropriate amount of phosphoric acid and ammonia water to adjust the pH value to 8.0±0.5.

Embodiment 2

[0044] Add the following substances to 600 mL of ionized water: 10 g of ethanolamine and diethanolamine mixture, 8 g of citric acid and polyethylene glycol mixture, 5.0 g of toluenetriazole, 0.5 g of sodium dihydrogen phosphate, mix and stir, and then add water to 1 L , and add appropriate amount of dilute sulfuric acid and diethylamine to adjust the pH value to 6.5±0.5.

Embodiment 3

[0046] Add the following substances to 1L of deionized water: 80 g of a mixture of ethanolamine and triethanolamine, 50 g of a mixture of citric acid and polyethylene glycol, 20.0 g of 1-(2-hydroxy)ethyl-1H-5-mercapto-tetrazolium, ethylene glycol Amine tetramethylene phosphonic acid (EDTMP) 10.0g, stir after mixing, and add benzoic acid and ethanolamine to adjust the pH value to 7.5±0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com