Low-temperature hot-melt pressure-sensitive adhesive for disposable hygienic product and preparation method thereof

A hygienic product, low-temperature heating technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems such as equipment failure, difficulty in removal, and reduced production efficiency, so as to save machine maintenance costs , good initial tack and stickiness performance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

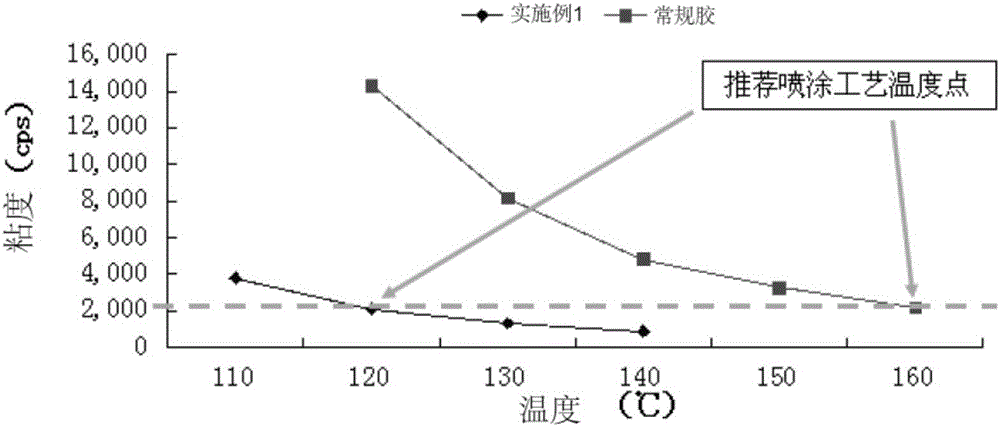

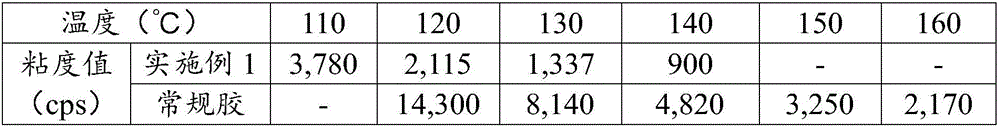

Embodiment 1

[0039] The low-temperature hot-melt pressure-sensitive adhesive for disposable hygiene products contains the following components in mass percentage: SBS rubber 13.7%; modified rosin resin 55.5%; naphthenic oil 29.3%; polyethylene wax 1%; antioxidant 0.5% .

[0040] The special low-temperature hot-melt pressure-sensitive adhesive for disposable sanitary products described in this embodiment is prepared by the following method:

[0041] (1) 10.0% SBS rubber (the model is Taiwan Rubber SBS4265), 3.7% SBS rubber (the model is Yuehua 188), 15% naphthenic oil (the model is 4010 produced by Karamay), 0.5% antioxidant (the model is 1010, 168) Mix evenly, heat to 140-150°C, continuously stir and vacuumize to -0.08mpa until the material is completely melted;

[0042] (2) In the above-mentioned melted material, add 55.5% modified rosin resin (the model is KOMO-KF399S), 14.3% naphthenic oil (the model is 4010 produced by Karamay), 1% polyethylene wax (the model is H-110 ), keep the hea...

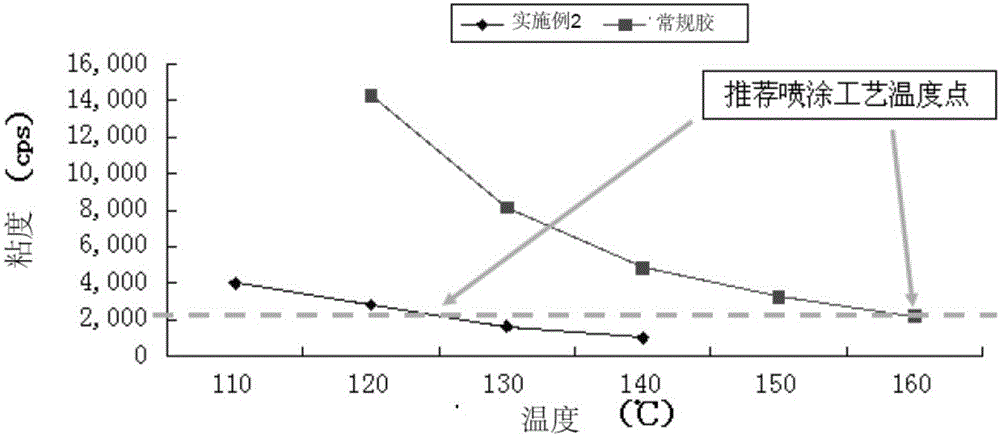

Embodiment 2

[0048] The low-temperature hot-melt pressure-sensitive adhesive for disposable hygiene products contains the following components in mass percentage: SBS rubber 13.7%; modified rosin resin 55.5%; naphthenic oil 29.3%; polyethylene wax 1%; antioxidant 0.5% .

[0049] (1) Mix 15% naphthenic oil (type 4010 produced by Karamay), 6% SBS (4270 rubber), 7.2% SBS (188 rubber), 0.3% antioxidant (type 1010, 168), and heat To 140 ~ 150 ℃, continuous stirring and vacuuming to -0.1mpa, until the material is completely melted;

[0050] (2) In the above-mentioned melted material, add 16% naphthenic oil (4010 produced by Karamay), 34% hydrogenated petroleum resin (Lanhua C5 2#), 20.5% hydrogenated petroleum resin (5600), 1% Fischer-Tropsch wax (H1), keep the heating temperature at 120-130°C, stir evenly, wait until it is completely melted, vacuumize until there are no bubbles, and the resulting mixture is a low-temperature adhesive for petroleum-based disposable sanitary products.

[0051] ...

Embodiment 3

[0056] The low-temperature hot-melt pressure-sensitive adhesive for disposable hygiene products contains the following components in mass percentage: SIS 10%; SBS 20%; modified rosin resin 40%; naphthenic oil 24.5%; 56# semi-refined wax 5%; Oxygen 0.5%.

[0057] Example 3 The low-temperature hot-melt pressure-sensitive adhesive for disposable sanitary products is prepared by the following method:

[0058](1) Mix 10% SIS, 20% SBS, 12% naphthenic oil, and 0.5% antioxidant evenly, heat to 140-150°C, continuously stir and evacuate to -0.06mpa until the material is completely melted;

[0059] (2) Add 40% modified rosin resin, 12.5% naphthenic oil, and 5% polyethylene wax to the above-mentioned melted materials, keep the heating temperature at 130-140°C, stir evenly, and wait until all materials are completely melted, pump Vacuum until there are no air bubbles to obtain the special low-temperature hot-melt pressure-sensitive adhesive for disposable sanitary products.

[0060] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com