Steel plate feed roller for pressing ship body forming plates of large hydraulic machine

A technology of hydraulic press and feeding roller, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc. It can solve the problems of long feeding table and large format of forming boards, and achieve the effect of smooth and accurate lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

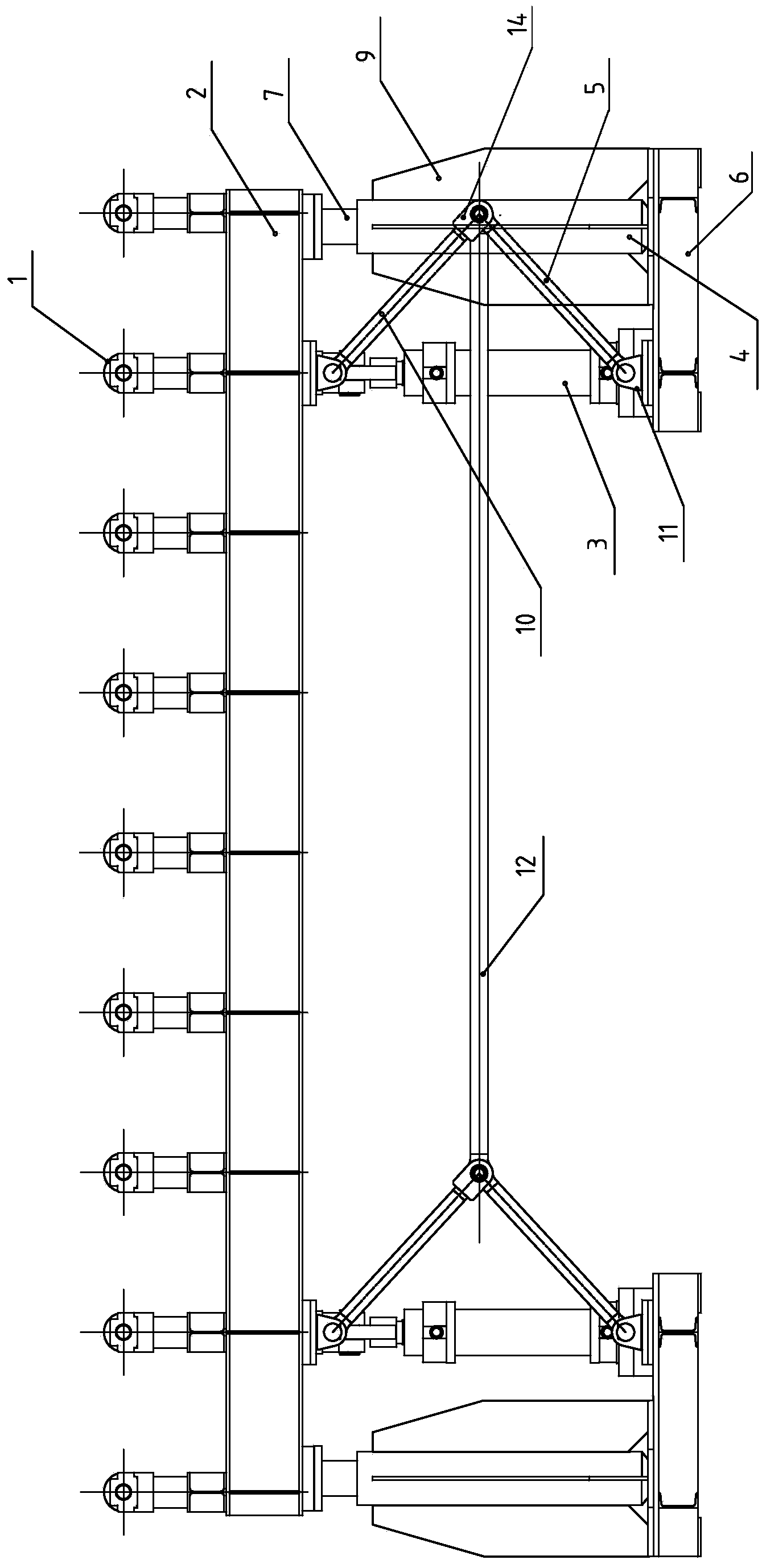

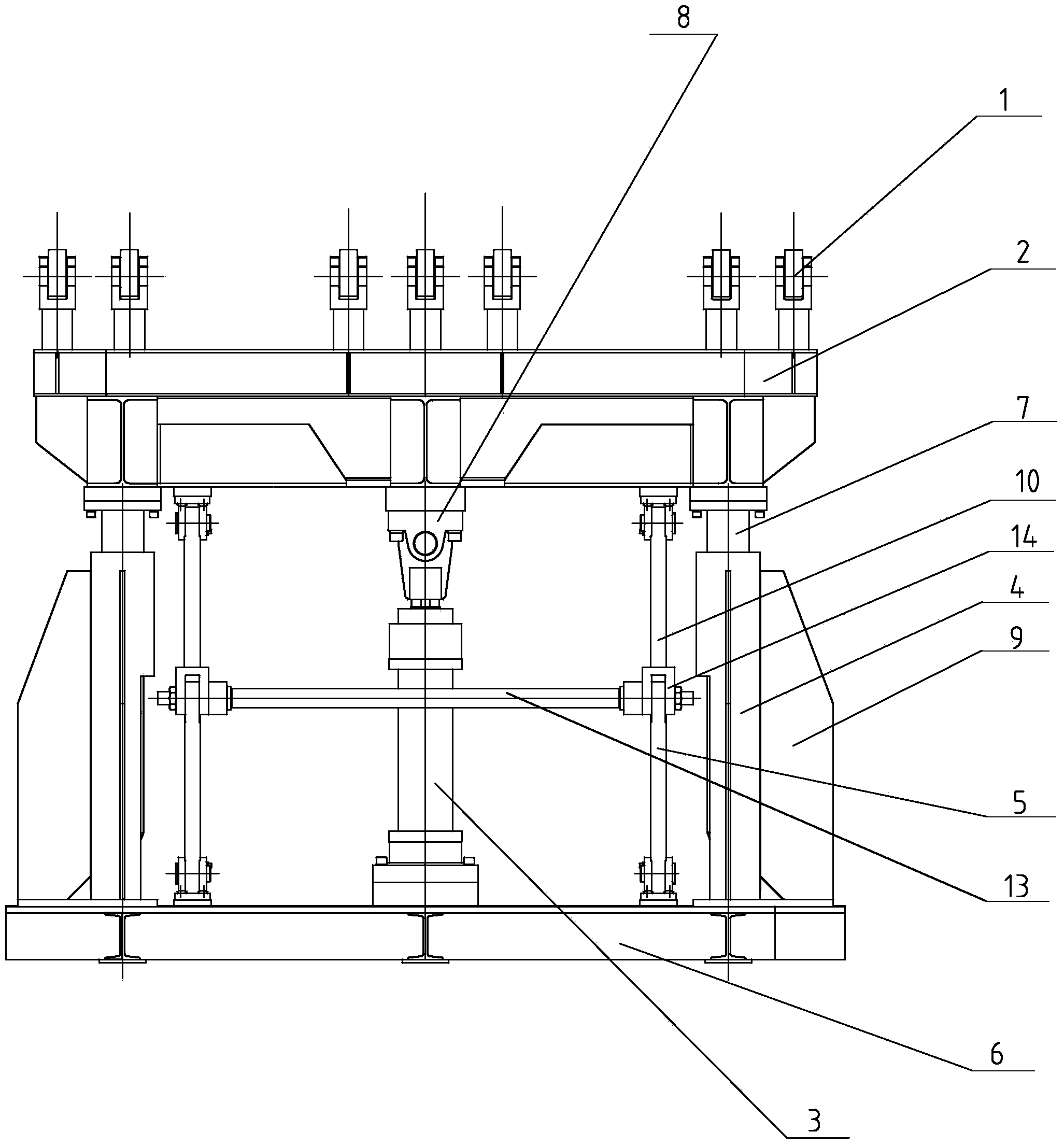

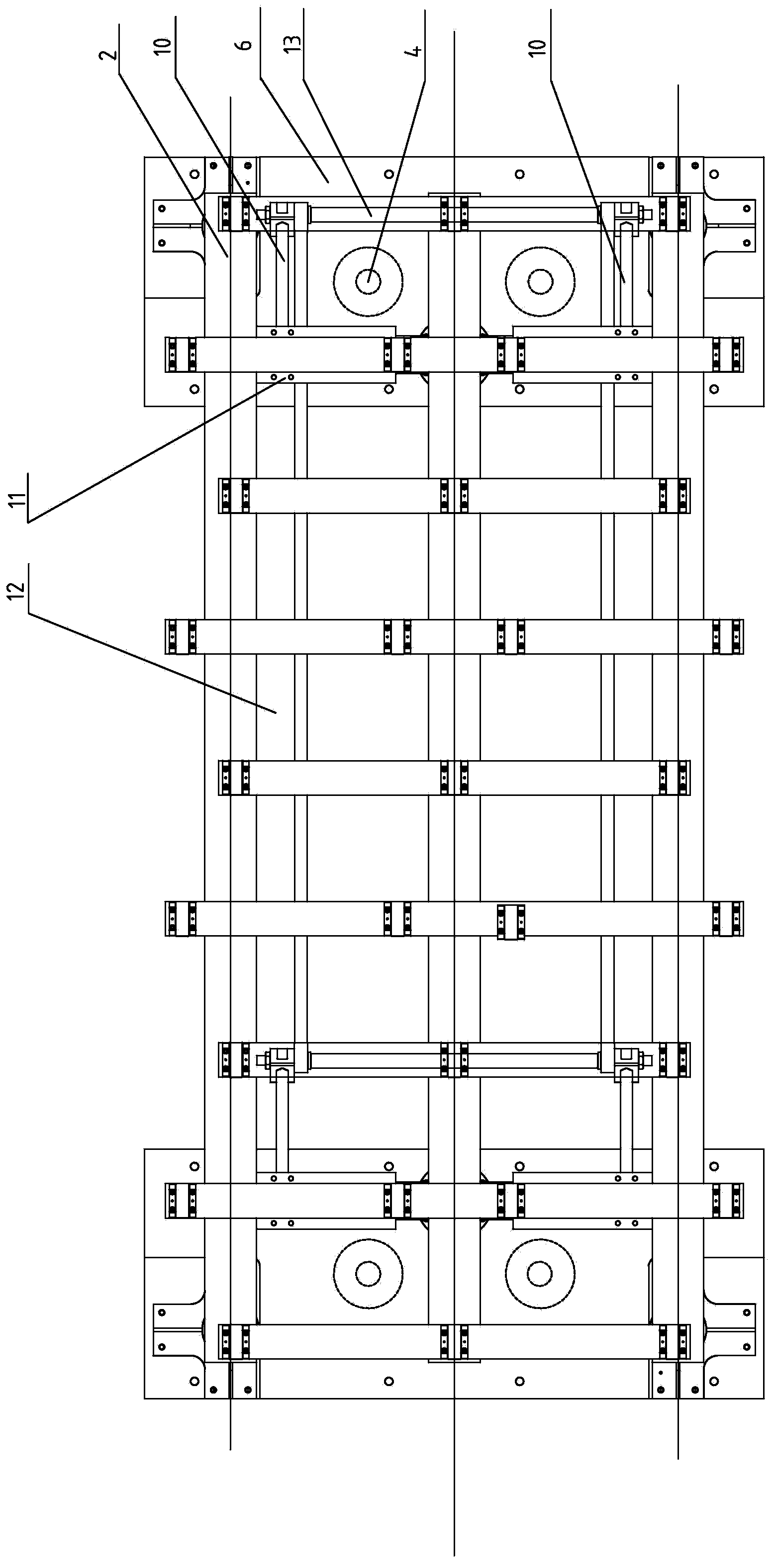

[0013] figure 1 , 2 Shown in , 3 is the concrete embodiment of the present invention, and it is the steel plate feeding roller table that the large-scale hydraulic press that presses the hull forming plate that manufactures 10,000-ton hull shell is used, it is characterized in that: steel plate feeding roller is installed on the site corresponding to the position of the hydraulic press Road; the steel plate feeding roller table is composed of a base, a guiding device, a support 2, a hydraulic cylinder 3 and an idler assembly, and a base composed of two horizontal bottom members 6 is installed in accordance with the shape and size of the pressed and formed plate 4 guide devices are installed symmetrically on the top surface of the horizontal bottom member 6 on both sides of the longitudinal centerline of the base, and each of the guide devices is equipped with a guide post 7 that slides up and down in the guide sleeve 4; The top of each guide post 7 described above is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com