Metal tube laser cutting machine capable of automatic feeding and sorting

A laser cutting machine and metal pipe technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of insufficient continuous production, production accidents, etc., and achieve the effect of high work efficiency and fully automated production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following completes the description of the present invention through specific embodiments. It should be noted that the following orientation words "front", "back", "left", "right", "upper" and "lower" are provided for convenience of description and do not constitute specific limitations. In addition, it should be noted that the drawings provided are schematic diagrams, not engineering drawings with specific dimensions and ratios. For the convenience of explaining the structure, some parts may be enlarged or reduced.

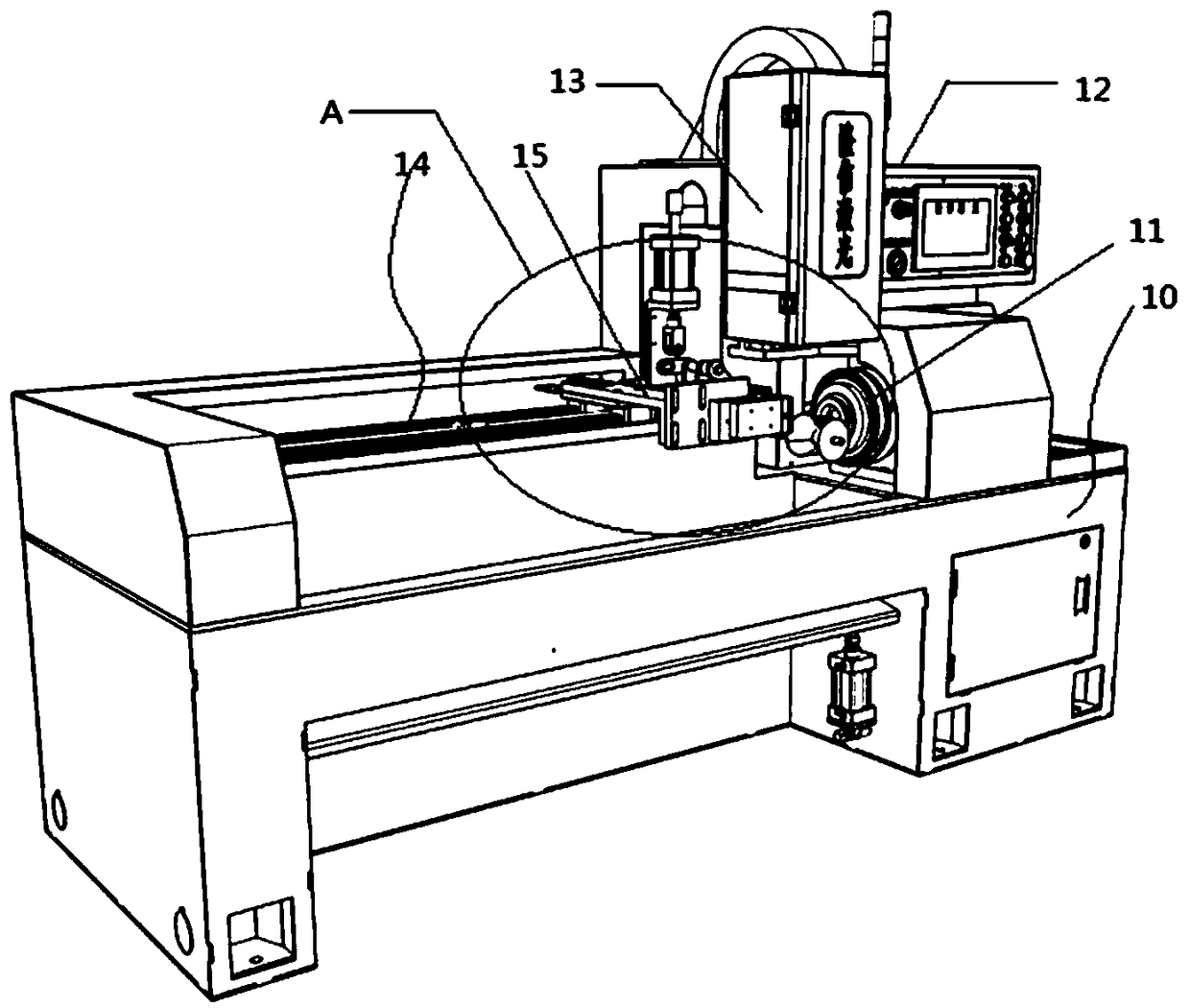

[0035] See attached figure 1 , with figure 1It is a structural schematic diagram of a manual metal pipe laser cutting machine in the prior art. Existing manual laser cutting machine comprises frame 10, pipe fixture 11, electric control system 12, laser cutter 13, guide rail 14 and positioner 15, wherein pipe fixture 11, electric control system 12, laser cutter 13 and guide rail are Installed directly above the frame 10, the pipe clamp 11 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com