Automatically length-fixing plate shearing machine

An automatic length-fixing and shearing machine technology, which is applied in the field of forging machinery, can solve problems such as low production efficiency and easy safety accidents, and achieve the effects of improving production efficiency, avoiding coordination contradictions, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

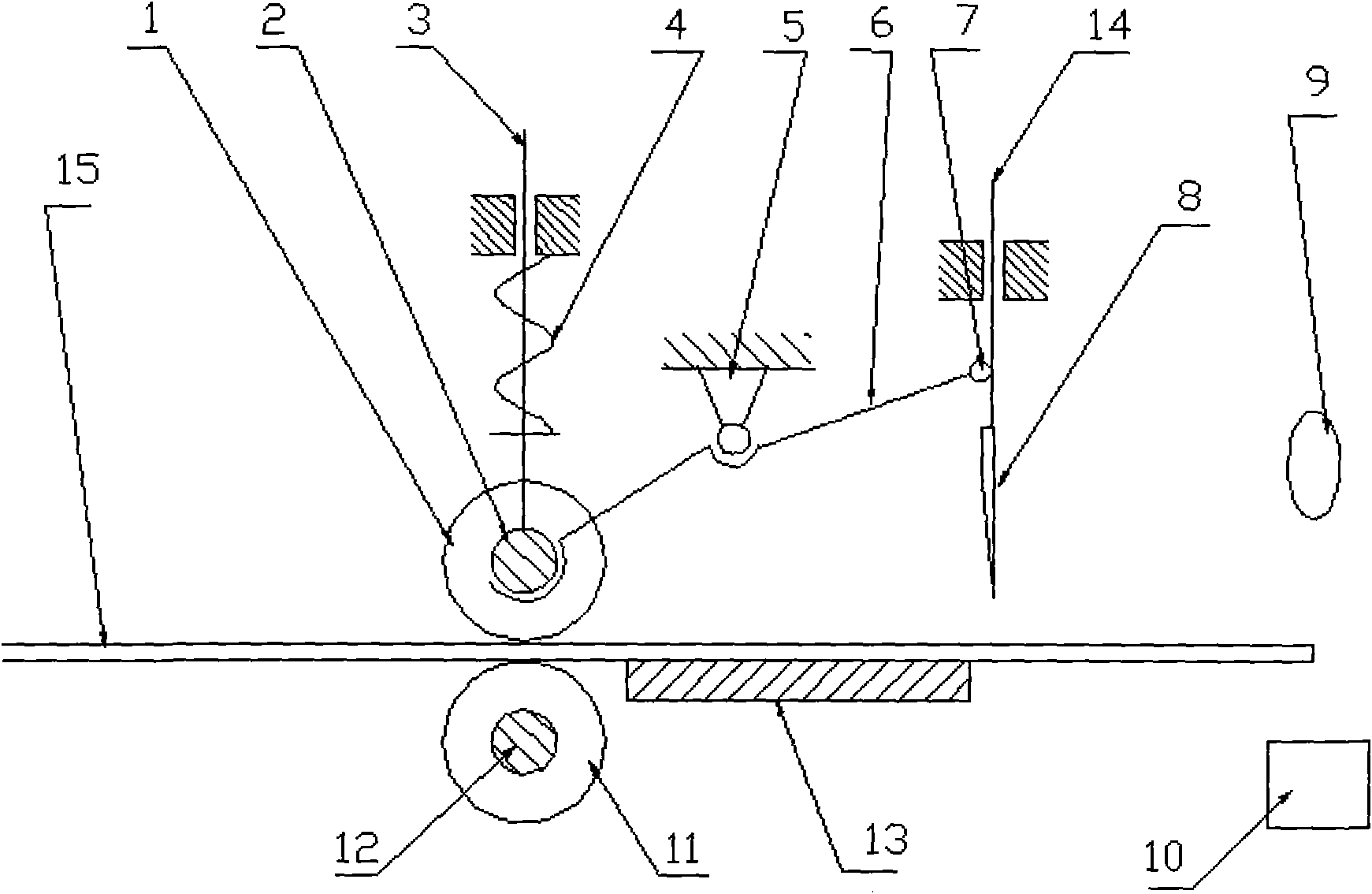

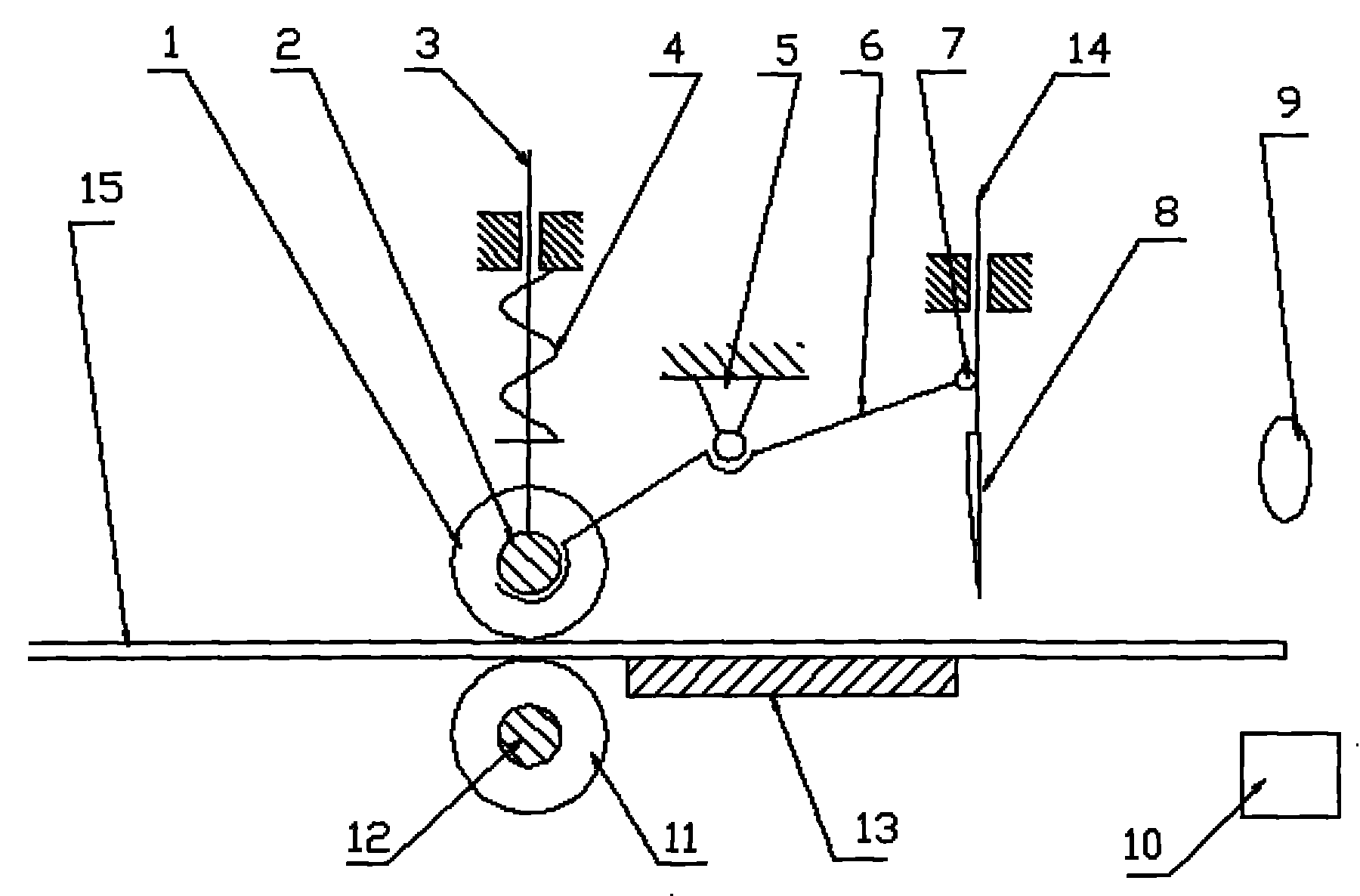

[0009] Install the pressing roller (1) on the upper surface (3) of the pressing bar through the pressing roller shaft (2), install the compression spring (3) on the pressing bar (3), and install it in the middle of the connecting rod (6) at an appropriate position On the support (5), one end of the connecting rod (6) is hinged with the pressing roller shaft (2), and the other end is hinged with the cutter seat (14) through the connecting rod pin (7), and the cutter Installed on the top of the cutter seat (14), the infrared emitting device (9) and the infrared receiving device (10) are symmetrically installed at appropriate positions on both sides of the guide rail (13). At the same time, the infrared emitting device (9) and the infrared receiving device The position of the device (10) in the guiding direction of the guide rail (13) can be adjusted. The guide rail (13) is installed and fixed on the shearing machine, and the direction of its guidance is perpendicular to the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com