Oil-pressure type steel pipe draw-bench

A drawing machine and hydraulic technology, applied in the field of steel pipe processing equipment, can solve the problems of cumbersome process and unfavorable production automation, and achieve the effect of high degree of automation, stable drawing, and guaranteed drawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

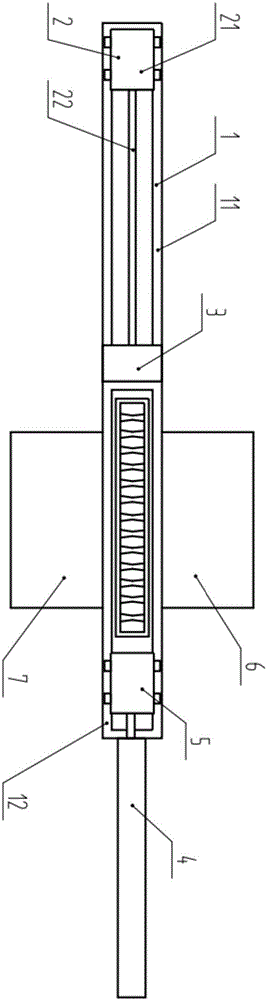

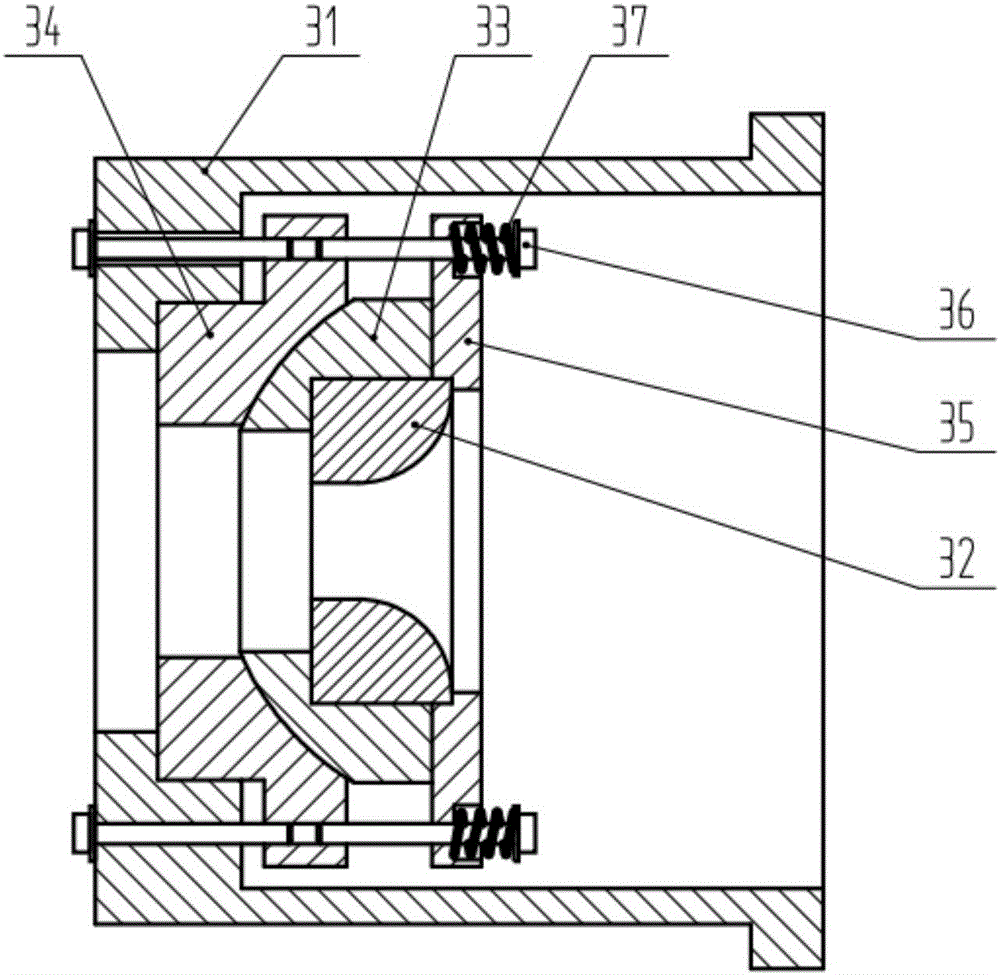

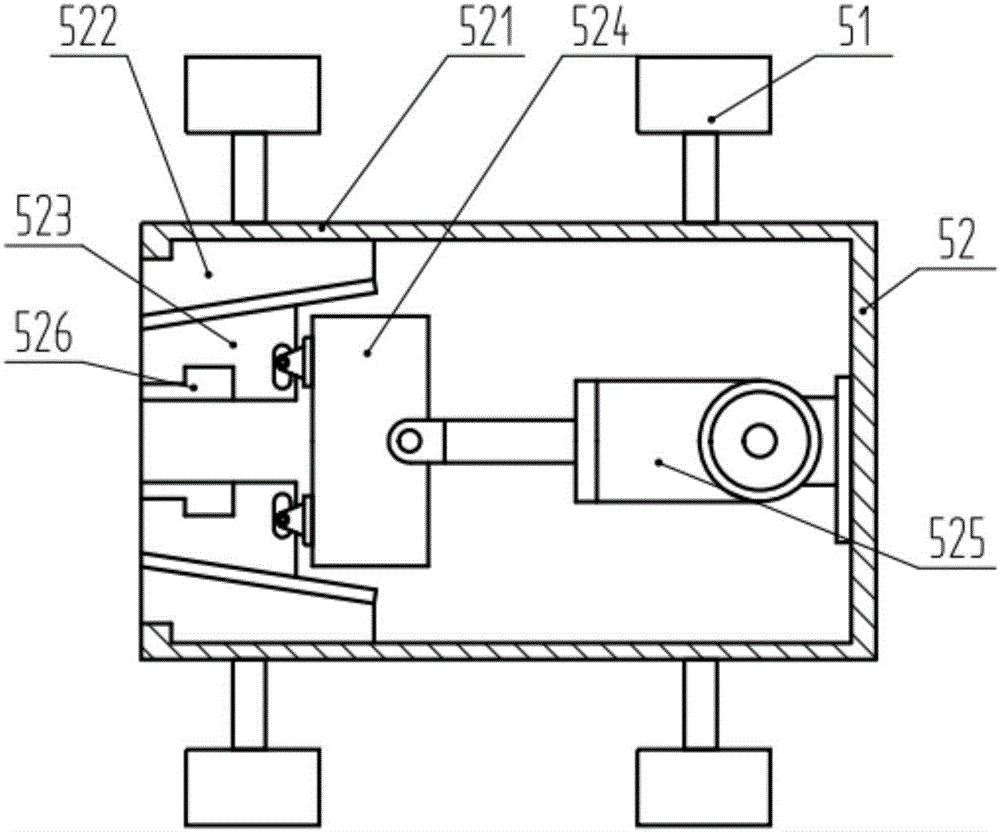

[0019] as attached Figure 1-4 The hydraulic steel pipe drawing machine includes a frame 1, the frame 1 includes an auxiliary frame 11 and a main frame 12, and the core rod assembly 2 is installed on the auxiliary frame 11, and the core rod assembly 2 includes a mandrel trolley 21 and a mandrel 22 installed on the mandrel trolley 21, the mandrel trolley 21 can move back and forth on the auxiliary frame 11; one of the main frame 12 close to the auxiliary frame 11 The drawing die assembly 3 is installed on the side, and the drawing die assembly can be lifted up and down relative to the main frame; the side of the main frame 12 away from the auxiliary frame 11 is equipped with a hydraulic cylinder 4, and the main The drawing trolley 5 that can move back and forth on it, the movement of the drawing trolley 5 relative to the main frame 12 is driven by the hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com