Full-automatic punching machine

A punching machine, fully automatic technology, applied in metal processing and other directions, can solve the problems of large punching machine, unable to achieve automatic and precise positioning, unable to achieve automatic feeding and automatic material receiving, etc., to save rack volume and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

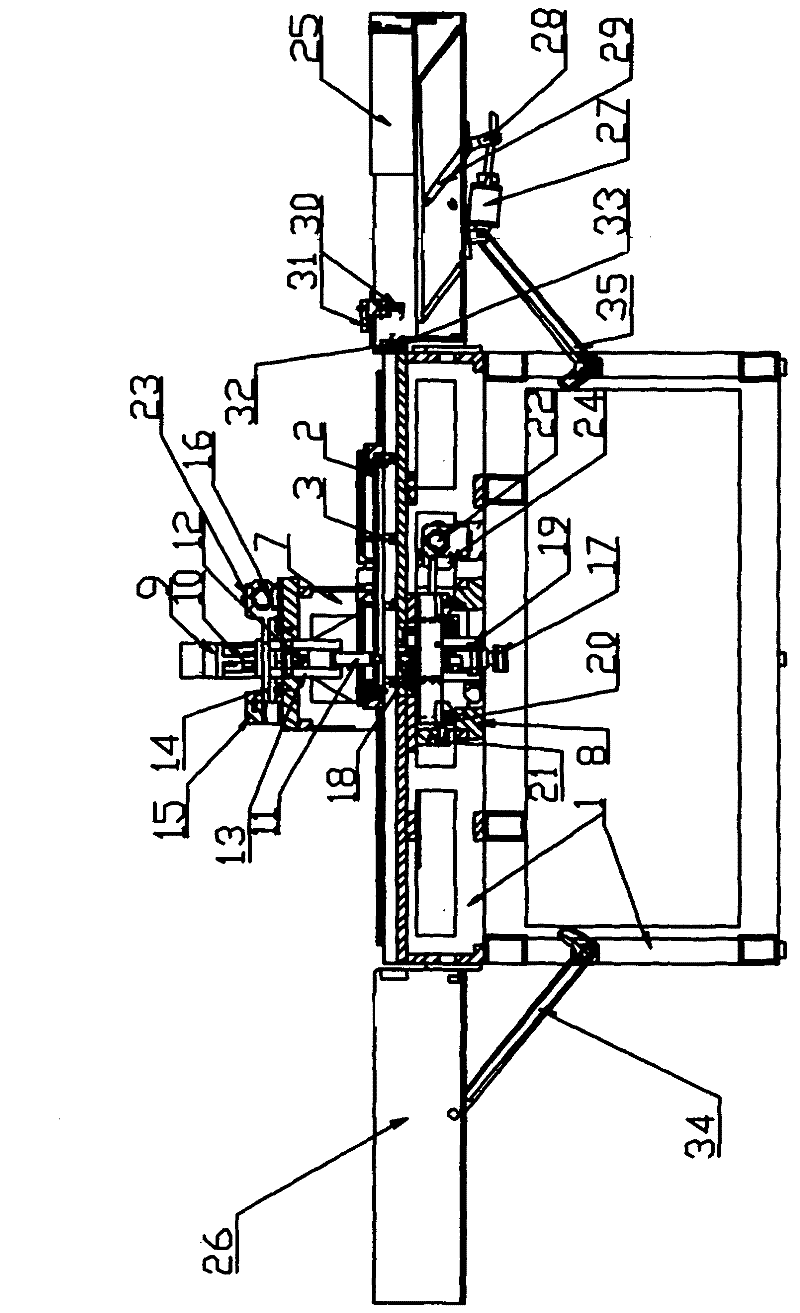

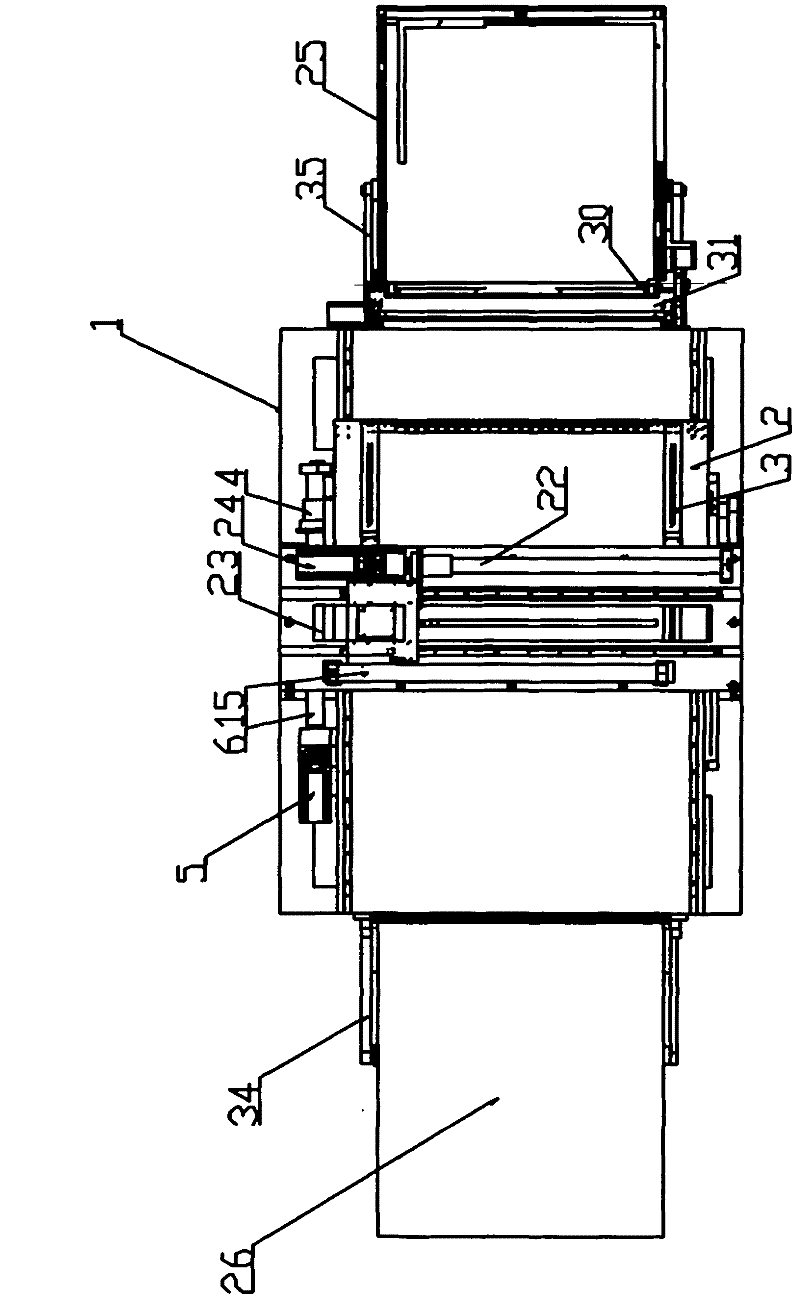

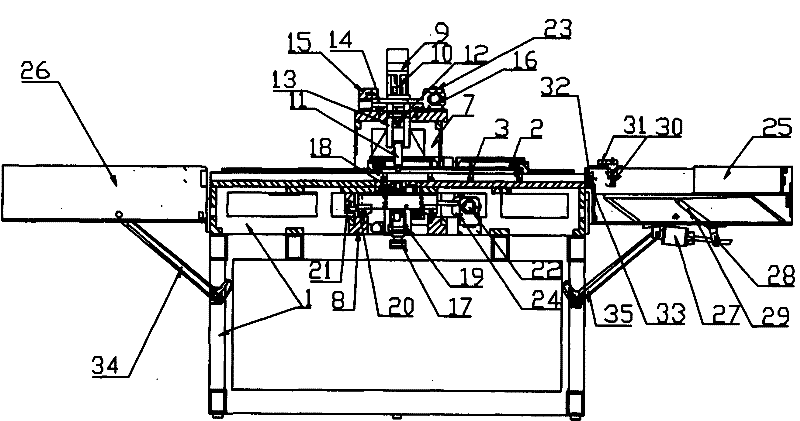

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , 2 , a fully automatic punching machine, including a frame 1, a slidable feeding frame 2 is provided on the frame 1, a vacuum suction cup 3 is provided on the feeding frame 2, and the position of the vacuum suction cup 3 on the feeding frame 2 can be adjusted according to the processing The width of the piece is properly adjusted. One side of the feeding frame 2 is provided with a sliding sleeve 4, which is matched with the screw 6 on the motor 5. An upper punching frame 7 and The lower punch frame 8 and the upper punch frame 7 are provided with a cylinder 9, the cylinder connecting rod 10 is provided with an upper punch 11, one side of the upper punch 11 is provided with a camera 12, and one side of the shell 13 of the upper punch 11 A positioning rod 14 is provided, and the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com