Board cutting device

A cutting device and plate technology, applied in the field of machinery, can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, improving cutting quality, and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

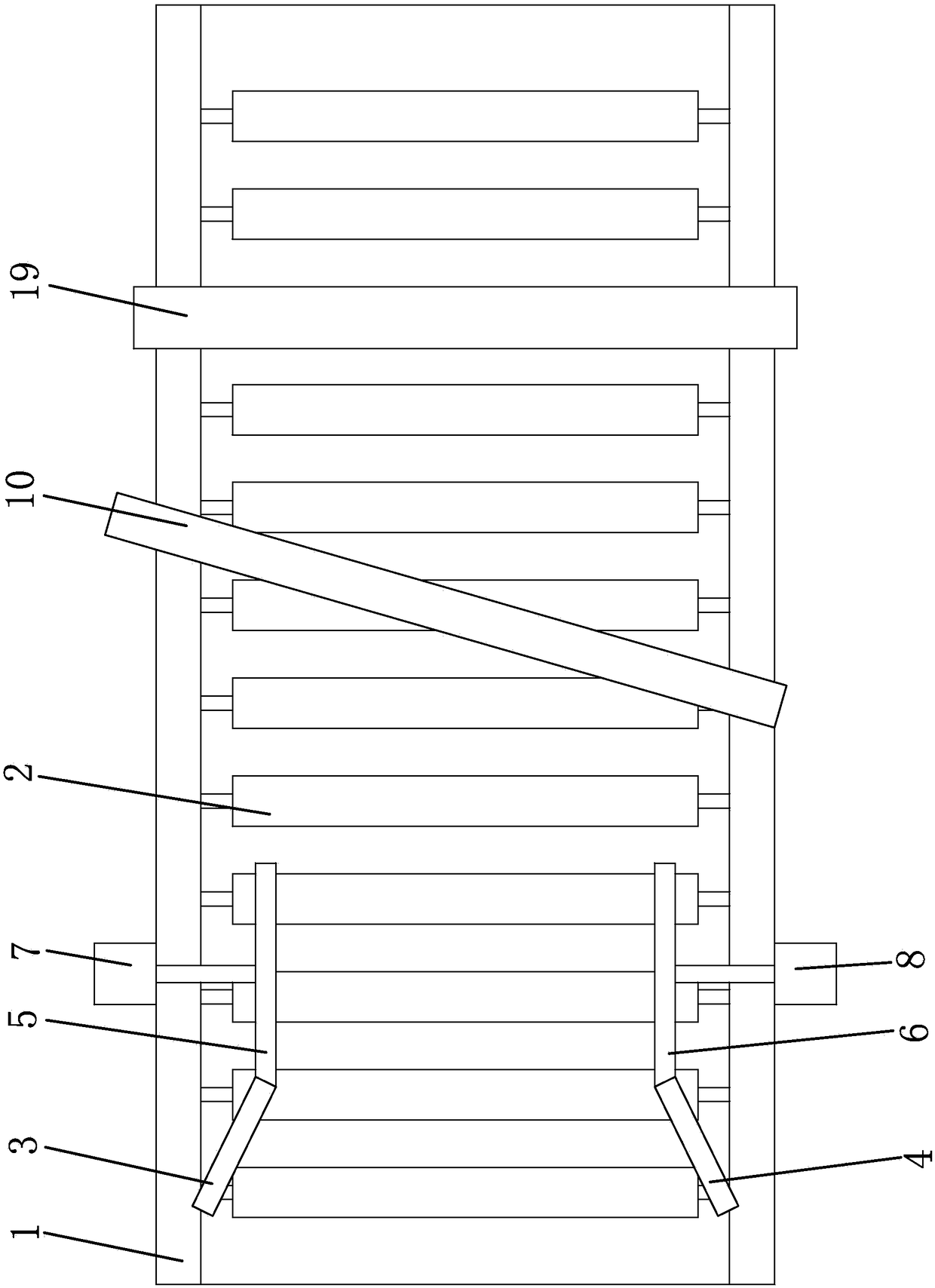

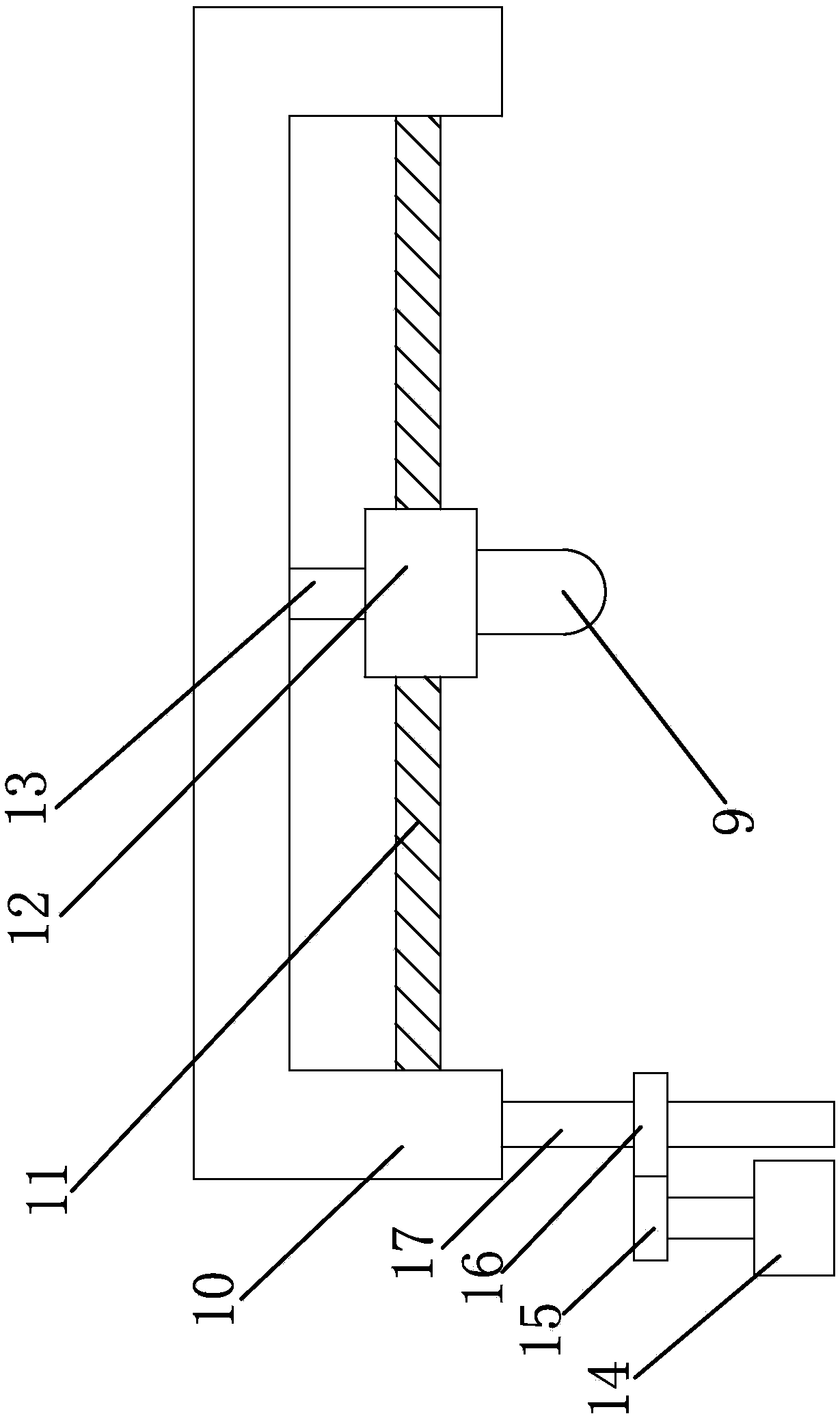

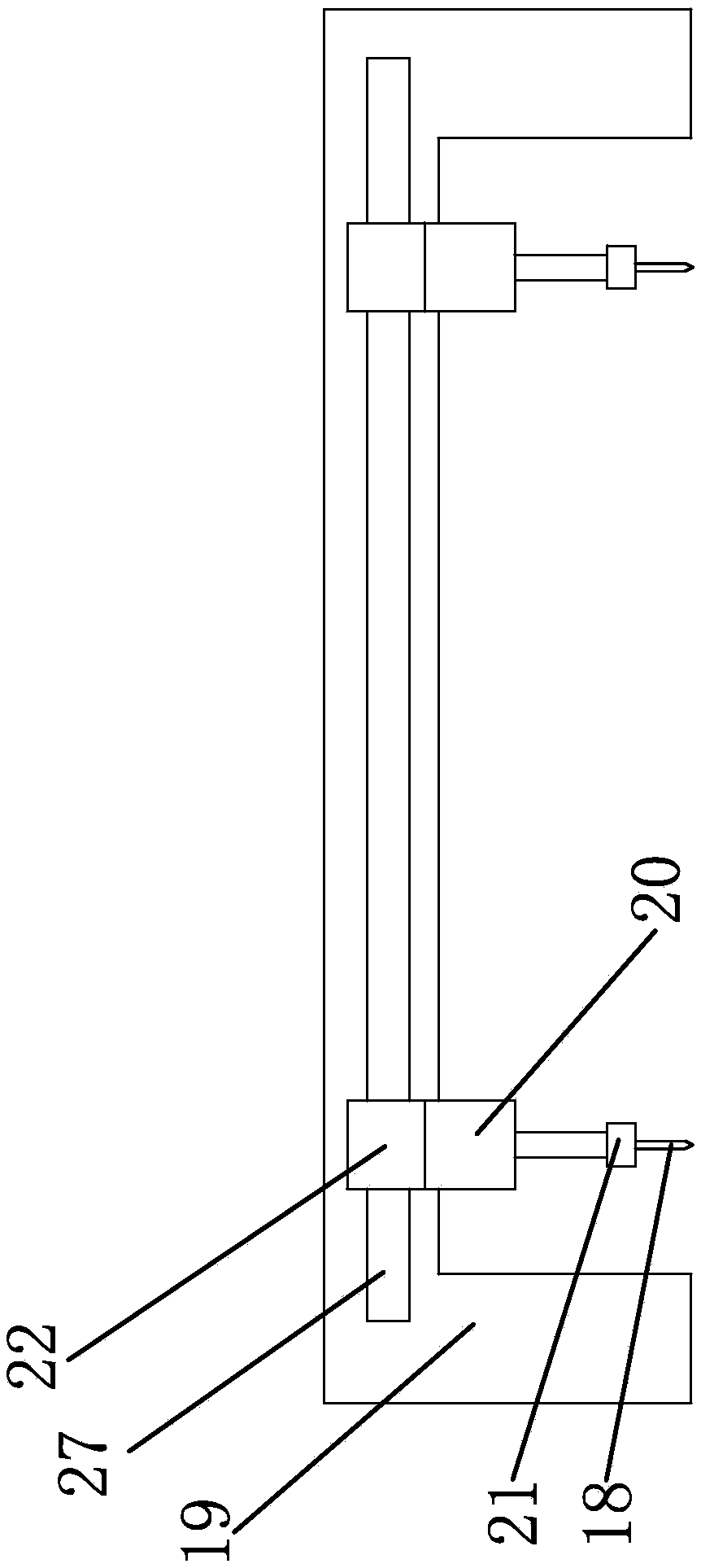

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a plate cutting device includes a strip-shaped workbench 1. The workbench 1 has an input end and an output end. The workbench 1 is provided with a conveying mechanism that can drive the plate forward, and the input end is provided to prevent the plate from The anti-deviation mechanism for offset, the top of the frame is also equipped with a horizontal cutting mechanism for cutting the sheet perpendicular to the sheet conveying direction, and the top of the workbench 1 is provided with a longitudinal cutting mechanism for cutting the sheet along the sheet conveying direction, the output end It is equipped with a blanking mechanism for automatic blanking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com