Automatic assembling device for coupler diaphragm

A technology of automatic assembly device and coupling, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, affecting assembly accuracy and quality, and pressing position offset, so as to reduce man-hours and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

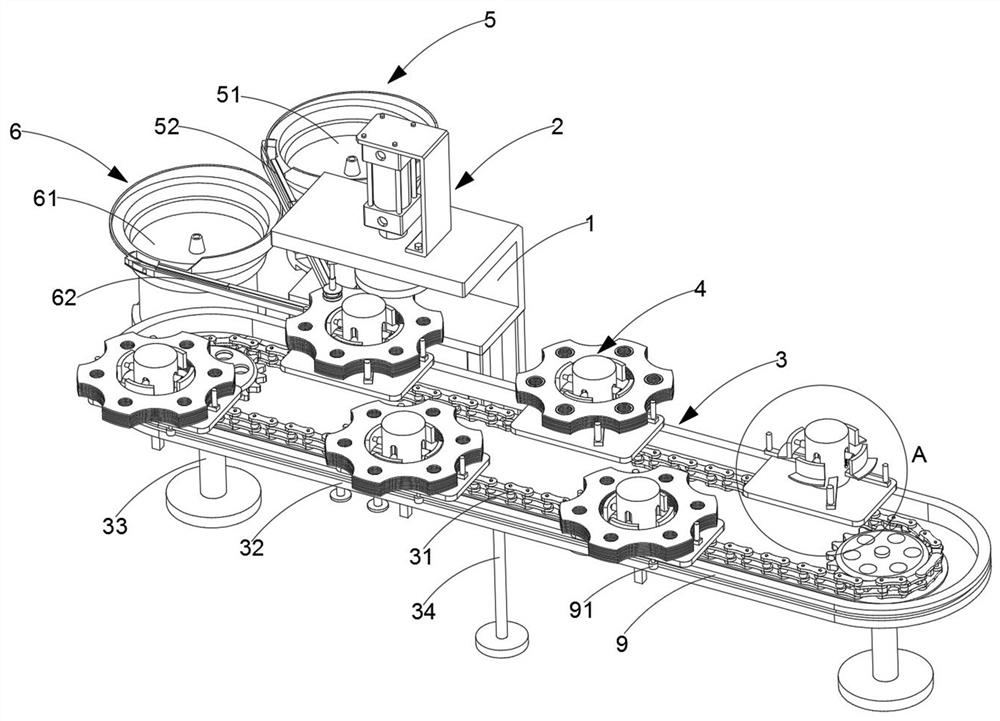

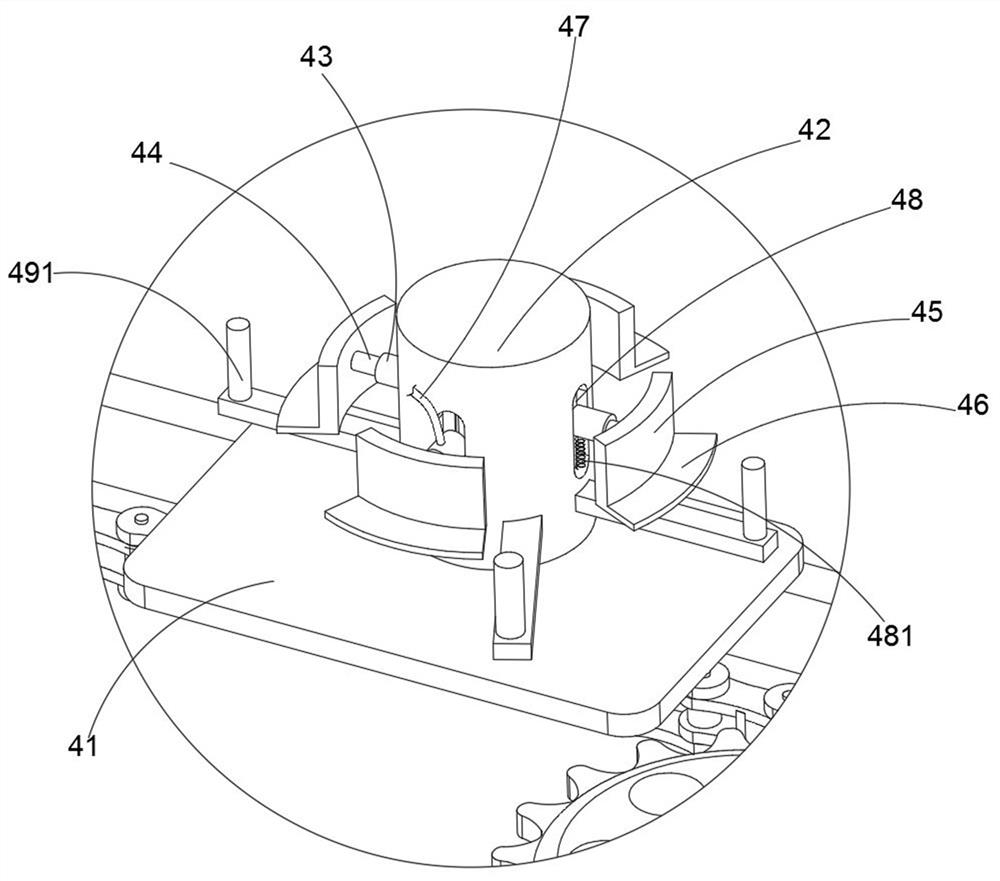

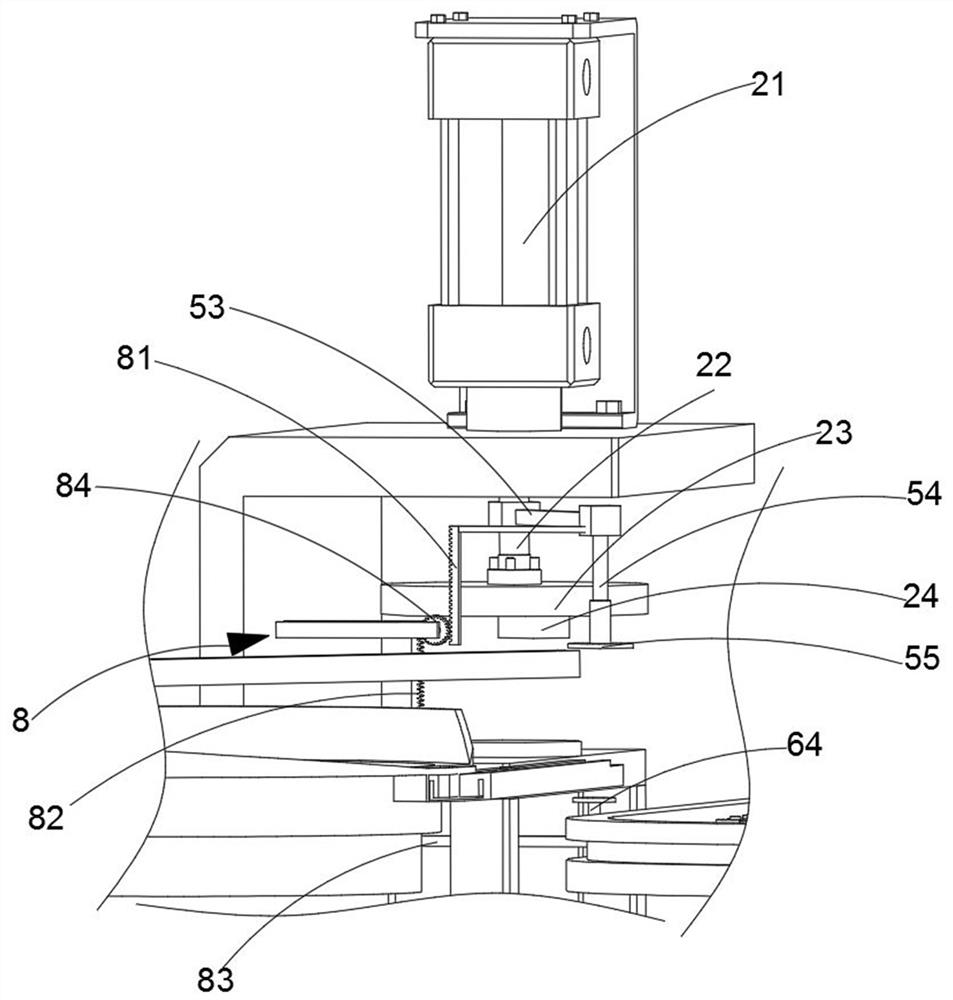

[0032] like Figure 1 to Figure 7 As shown in the figure, a coupling diaphragm automatic assembly device includes a frame 1, a pressing component 2 is arranged on the frame 1, a rotary component 3 is arranged below the frame 1, and a plurality of stable Assembly 4, the rear of the rotary assembly 3 is also provided with a feeding assembly a5 and a feeding assembly b6, a rotating assembly 7 is also provided below the rotary assembly 3, and a linkage assembly 8 is also provided between the...

Embodiment 2

[0043] like Figure 4 As shown in the figure, the same or corresponding parts as in the first embodiment are marked with the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment The point is that both the negative pressure suction cup 55 and the lifting plate 65 are provided with buffer protection pads.

[0044] Here, in this embodiment, buffer protection pads are provided on both the negative pressure suction cup 55 and the lifting plate 65, so that when the negative pressure suction cup 55 moves downward to cooperate with the screw ring 13, it plays a buffering role, and the lifting plate 65 moves upward. When moving together with the screw 14, it acts as a buffer, reduces the possibility of wear of the screw ring 13 and the screw 14, and increases the service life of the negative pressure suction cup 55, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com