Assembly line for gas valves

An assembly line and valve technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to control quality stability, low work efficiency, and high product repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

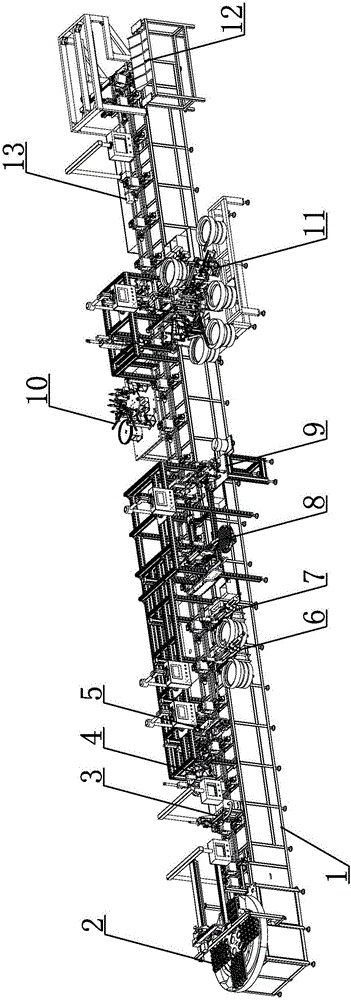

[0032] Such as figure 1As shown, the gas valve assembly line of the present invention includes a frame 1, on which an assembly main line 13 is installed, and the following stations are sequentially arranged on the assembly main line 13: the valve body front feeding station 2, the body dust suction station 3. Closed sub-direction identification and oiling station 4. Cork identification and assembly station 5. Small screw locking station, large screw locking station, short copper joint locking station 6, long copper joint locking post Position 7. Solenoid valve assembly and locking station 8. Fine-tuning spool assembly and locking station 9. Valve core assembly assembly station 10. Switch shaft assembly assembly station 11. Cover plate assembly and locking station and finished product unloading Bit 12.

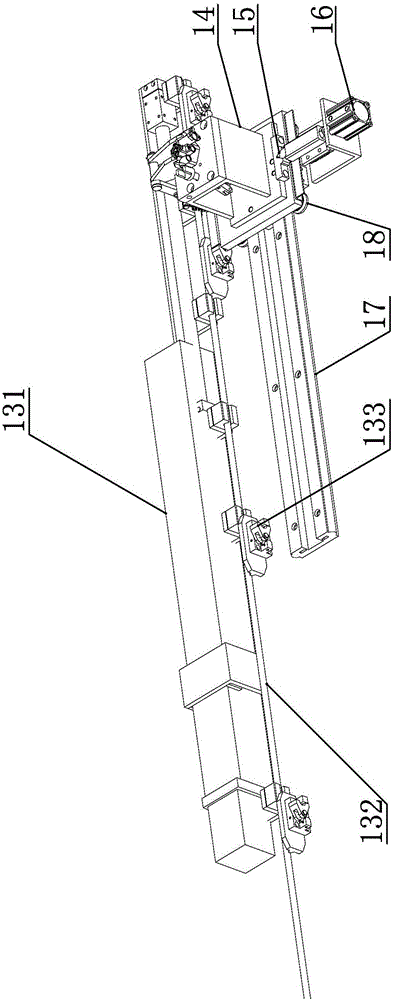

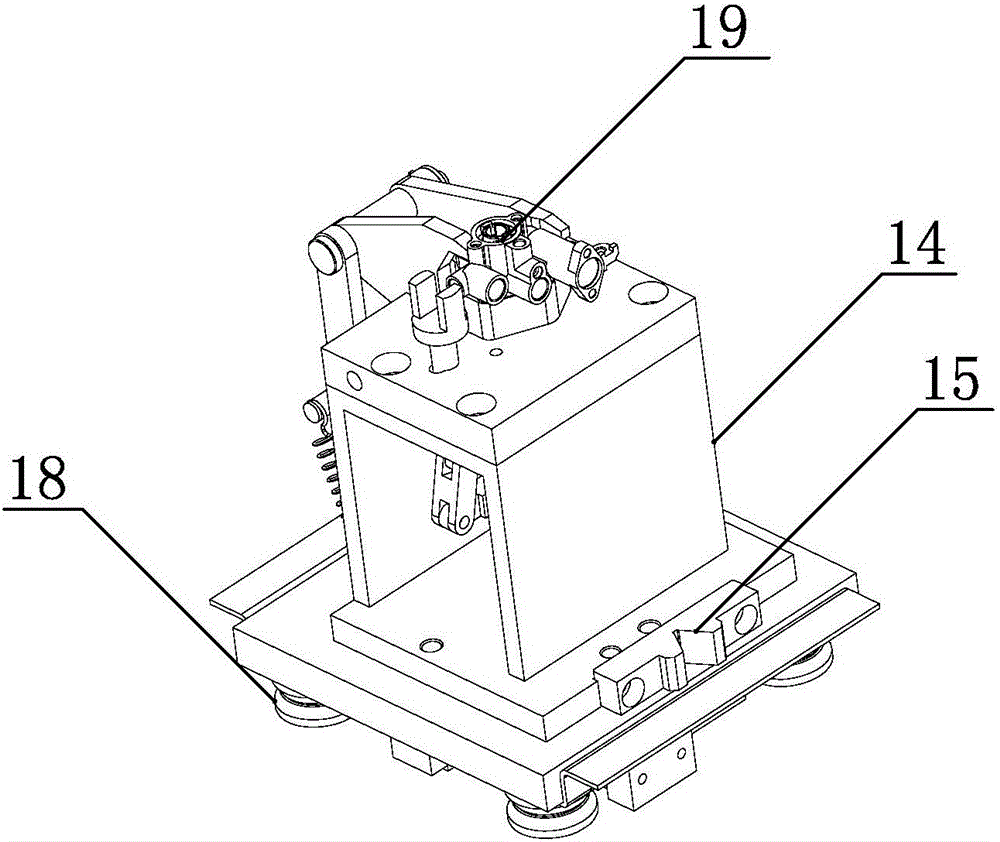

[0033] Such as figure 2 As shown, the main assembly line 13 includes a servo motor, a linear module 131 , an accompanying fixture 14 , a secondary positioning mechanism and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com