Variable-frequency centrifugal rod pipe blanking machine based on hydraulic compensation

A technology of centrifugal rod and material machine, which is applied in the field of frequency conversion centrifugal rod tube material cutting machine, which can solve the problems of uneven sharpness of sawtooth due to feed change, waste of raw materials, broken belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

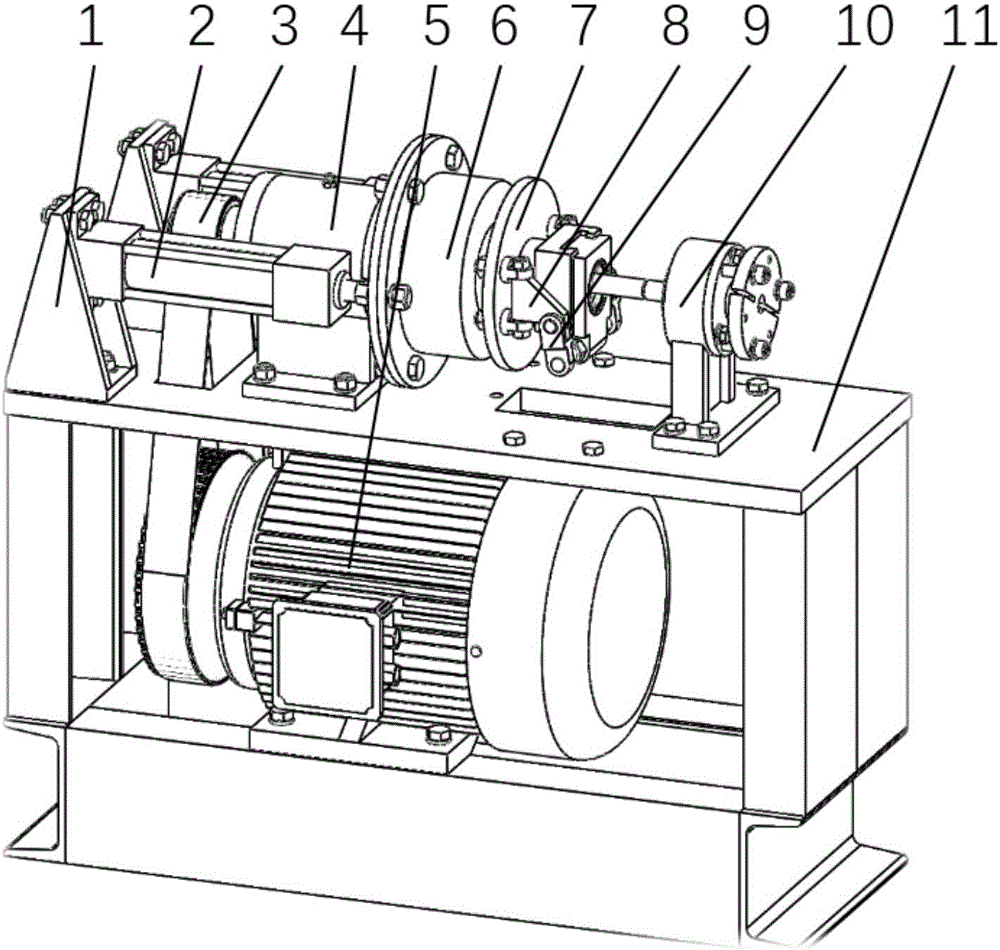

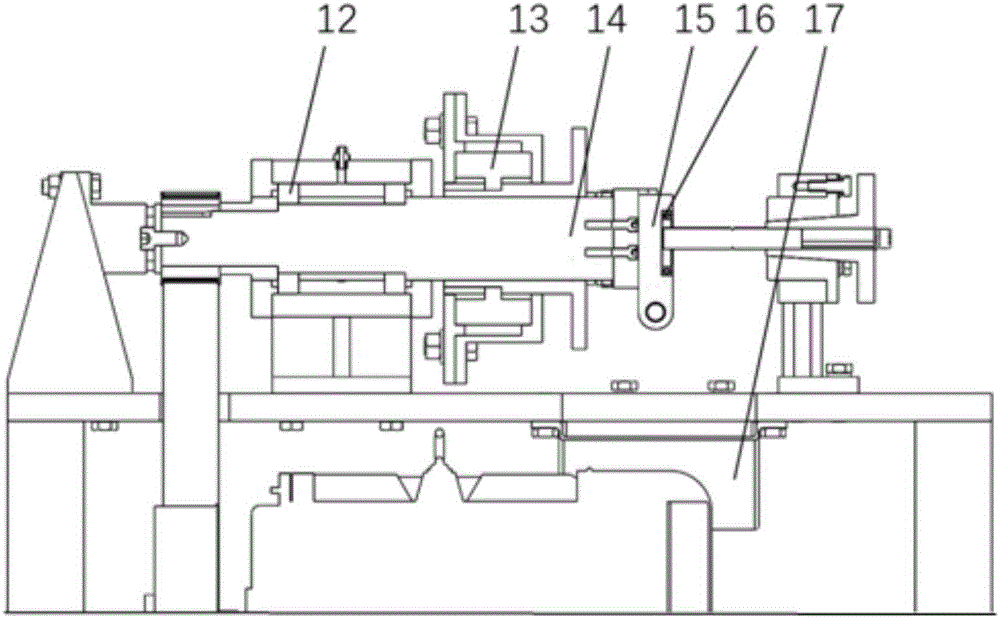

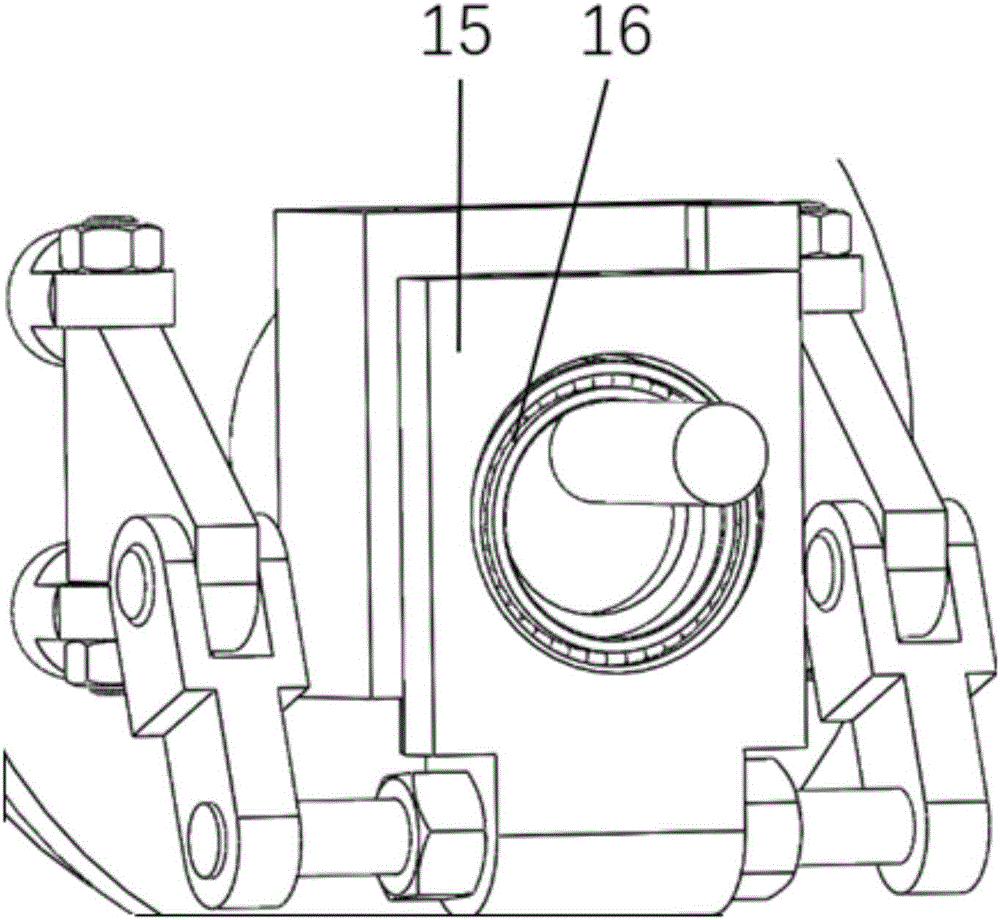

[0017] like figure 1 , figure 2 , image 3 As shown, the hydraulic compensation-based variable frequency centrifugal rod pipe blanking machine in the embodiment of the present invention includes a hydraulic cylinder support 1, a hydraulic cylinder 2, a timing belt 3, a fixed bearing box 4, a three-phase AC motor 5, and a sliding bearing box 6 , Rotating push plate 7, triangular block 8, connecting block 9, bar clamp 10, frame 11, deep groove ball bearing 12, two-way thrust ball bearing 13, main shaft 14, slider 15, inner surface with equal interval groove resistance Grinding bearing 16 and material block guide groove 17, the hydraulic cylinder support 1 is installed on one end of the frame 11, and is fixed on the frame 11 with bolts and nuts; the synchronous belt 3 connects the small pulley and the large pulley, so The small pulley is fixed on the main shaft 14, and the large pulley is fixed on the output shaft of the three-phase AC motor 5; The deep groove ball bearing 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com