Pallet box transferring device

A transfer device, pallet box technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of small carrying load, large labor consumption, poor flexibility, etc., to improve load-bearing capacity and overcome labor-intensive problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

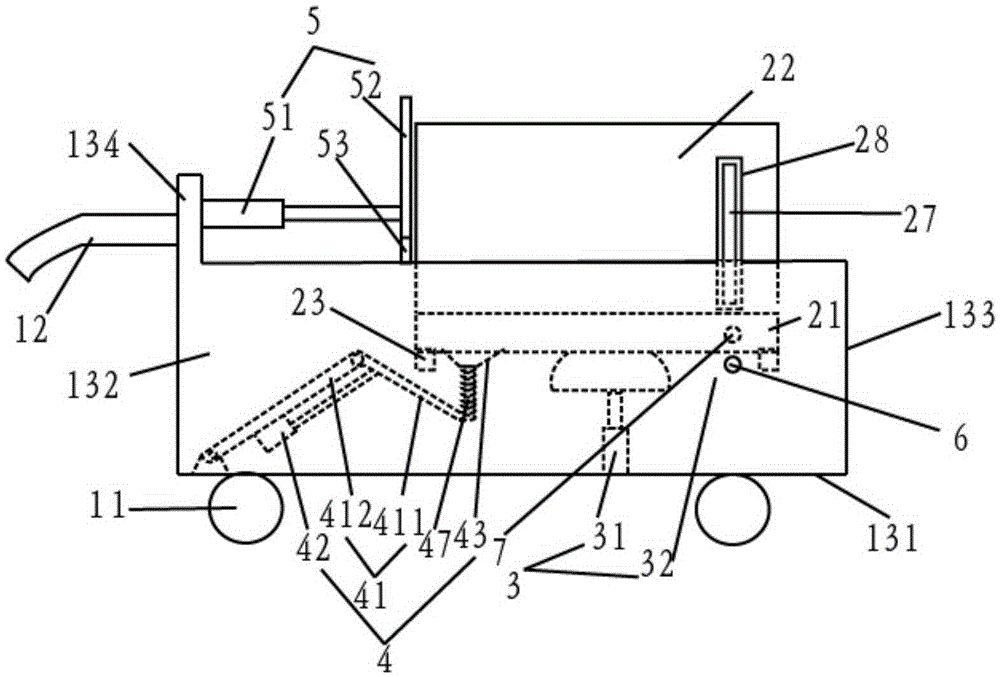

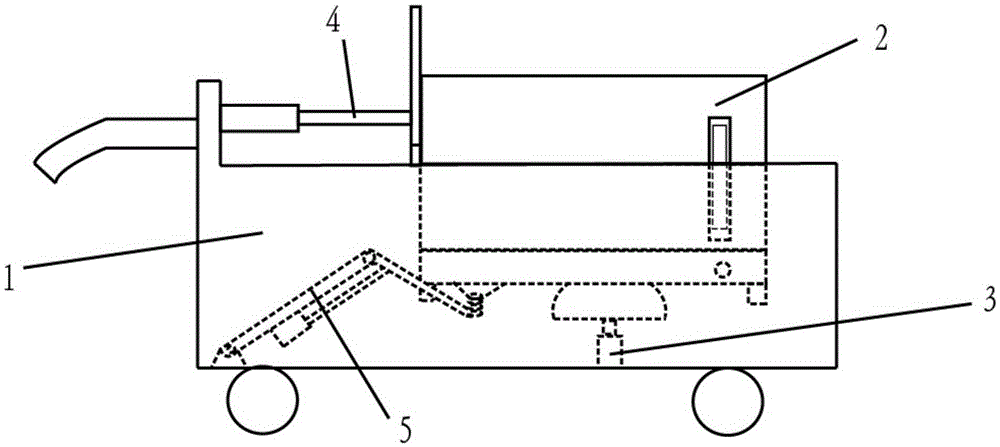

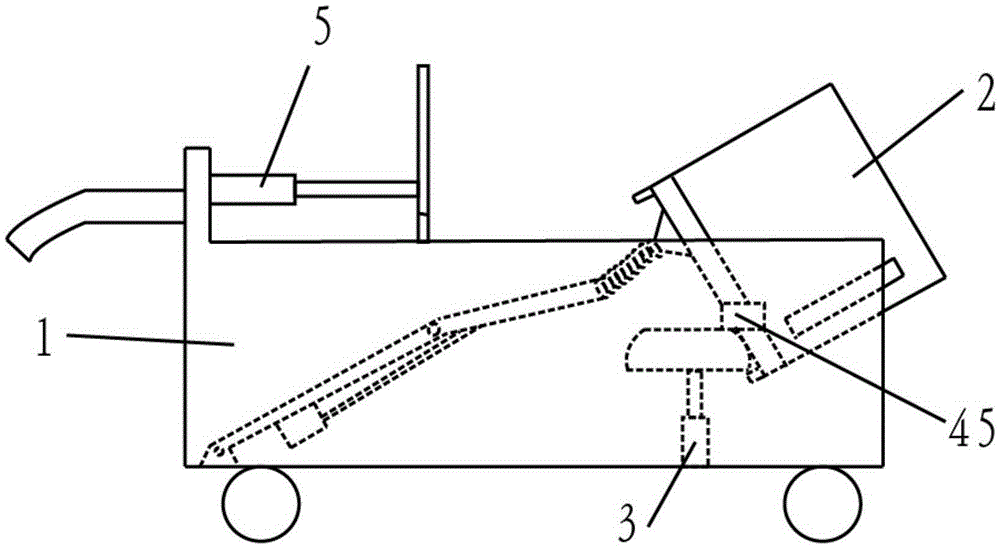

[0047] Such as Figure 1-3 As shown, this embodiment includes a transfer trolley 1 , a pallet box 2 , a lifting mechanism 3 , an overturning mechanism 4 and a pushing mechanism 5 .

[0048] The transfer trolley 1 includes several universal wheels 11, two handrails 12 and a top opening welded by a bottom plate 131, two side baffles 132, a front baffle 133, and a rear baffle 134, and the four sides and the bottom are closed. 1. A hollow cart body; the height of the front baffle 133 is lower than the height of the back baffle 134; the two armrests 12 are symmetrically arranged on the left and right ends of the outside of the back baffle 134; the The universal wheel 11 is arranged on the bottom of the bottom plate 131 .

[0049] Such as figure 1 , 5 , 6, 7, and 8, the pallet box 2 includes a pallet frame 21 and a side plate assembly 22, and several support plates 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com