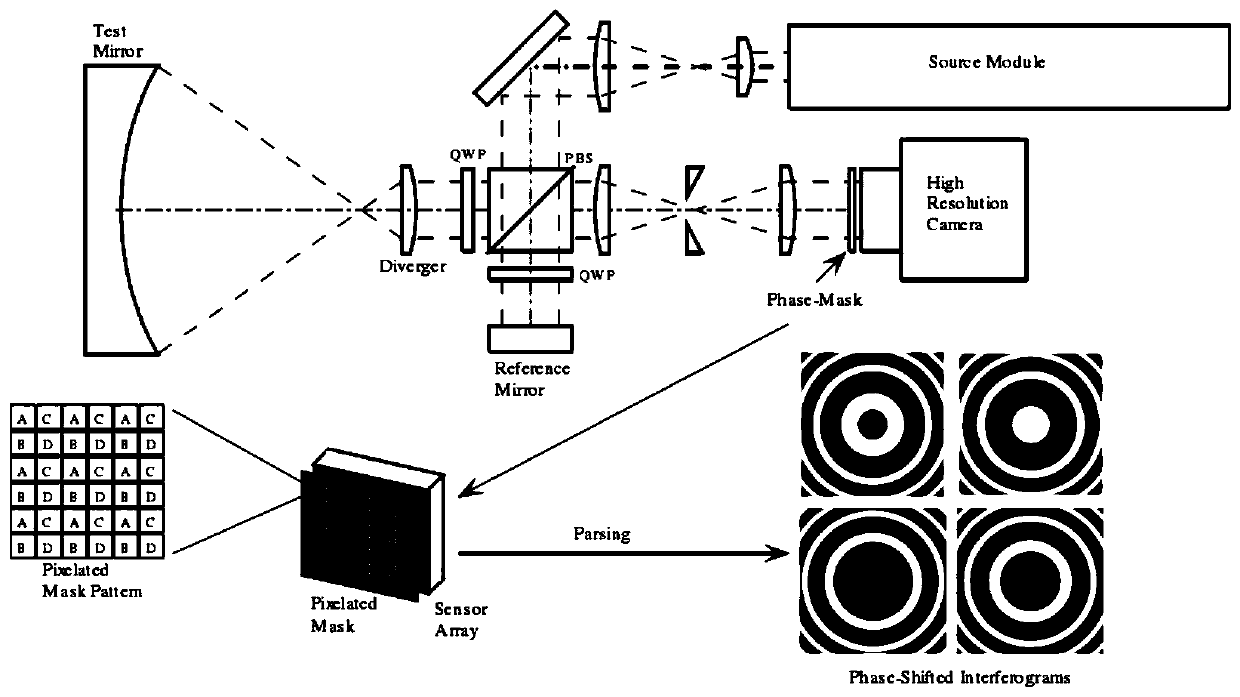

Spatial phase shift dynamic interferometer based on liquid crystal spatial light modulator and application of spatial phase shift dynamic interferometer

A spatial light modulator and dynamic interference technology, applied in the field of optical measurement, can solve problems such as difficult image registration, decreased measurement accuracy, and high processing cost, and achieve the effects of easy high-precision measurement, low energy consumption, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

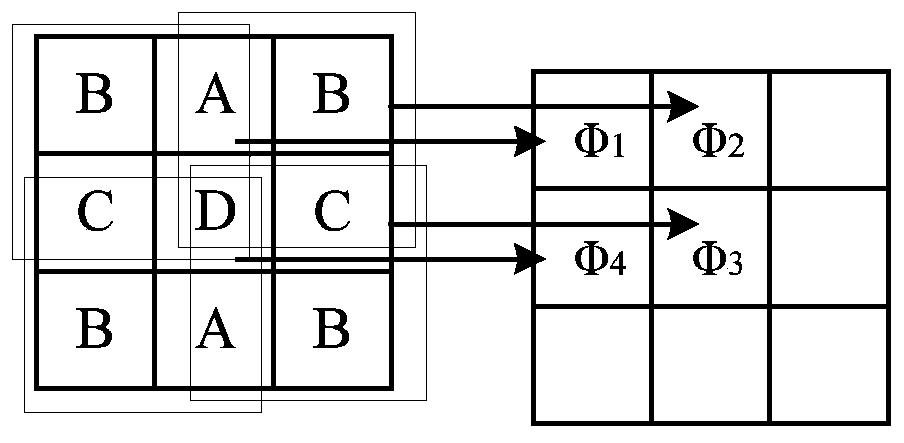

Method used

Image

Examples

Embodiment Construction

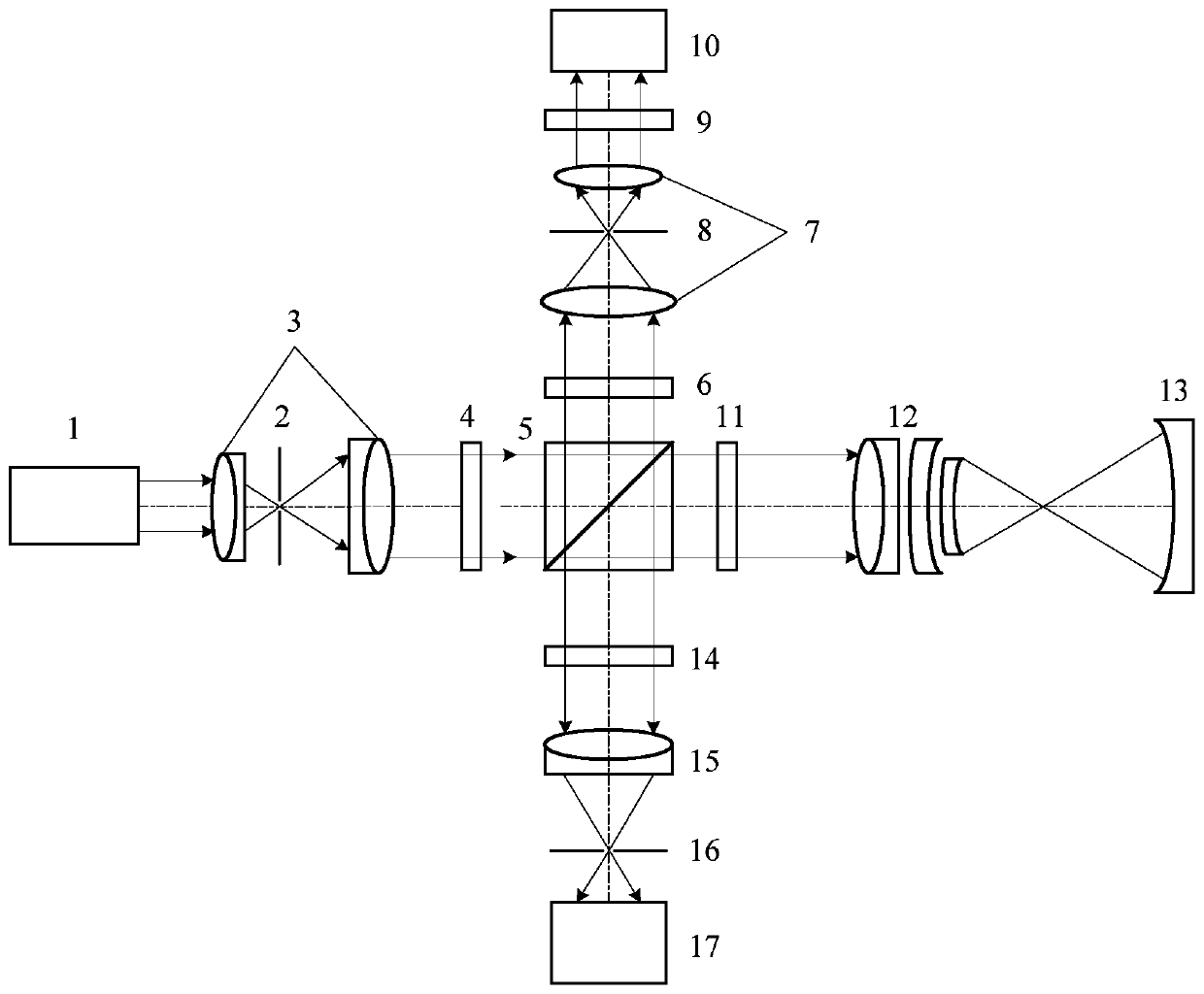

[0030] The spatial phase-shifting dynamic interferometer based on the liquid crystal spatial light modulator provided by the present invention, such as Figure 5 As shown, it includes: He-Ne laser 1, first pinhole filter 2, first collimator beam expander system 3, λ / 2 wave plate 4, polarization beam splitter prism 5, first λ / 4 wave plate 6, second Collimated beam expander system 7, second pinhole filter 8, polarizer 9, liquid crystal spatial light modulator 10, second λ / 4 wave plate 11, standard spherical lens 12, mirror under test 13, analyzer 14, imaging System 15, third pinhole filter 16 and photodetector 17; wherein:

[0031] The Gaussian film beam emitted by the He-Ne laser 1 passes through the microscope objective lens of the first collimator beam expander system 3, the first pinhole filter 2 and the telescopic objective lens of the first collimator beam expander system 3, and becomes uniform linearly polarized light, the azimuth angle of the linearly polarized light ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com