Test tube labeling machine with capabilities of automatic feeding and blanking

A technology for automatic loading and unloading and labeling machines, which is applied to labeling machines, labeling, labels, etc., can solve the problems of low efficiency of labeling devices, and achieve the effects of simple structure, convenient debugging, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention is described in detail below in conjunction with accompanying drawing:

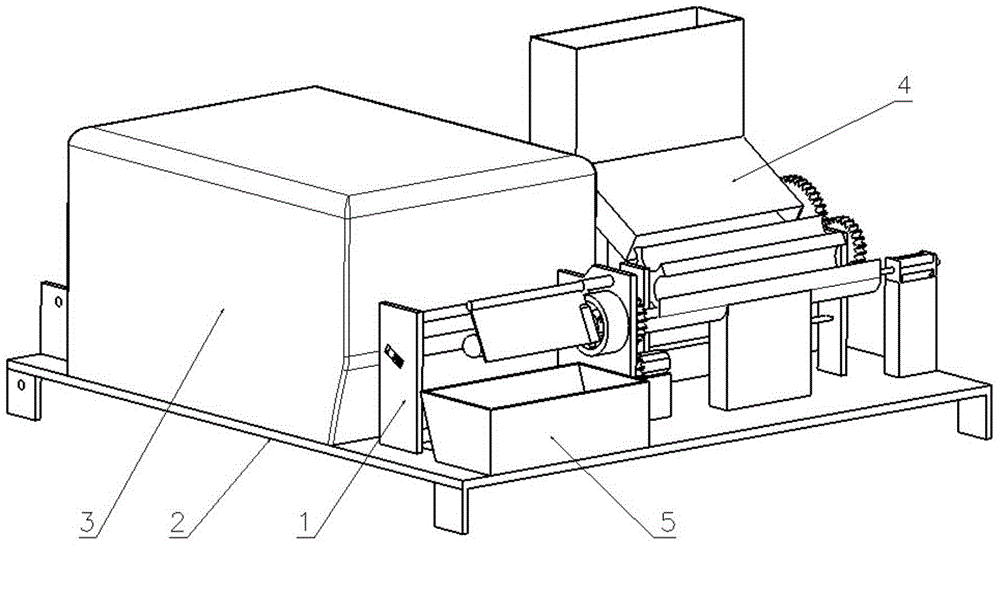

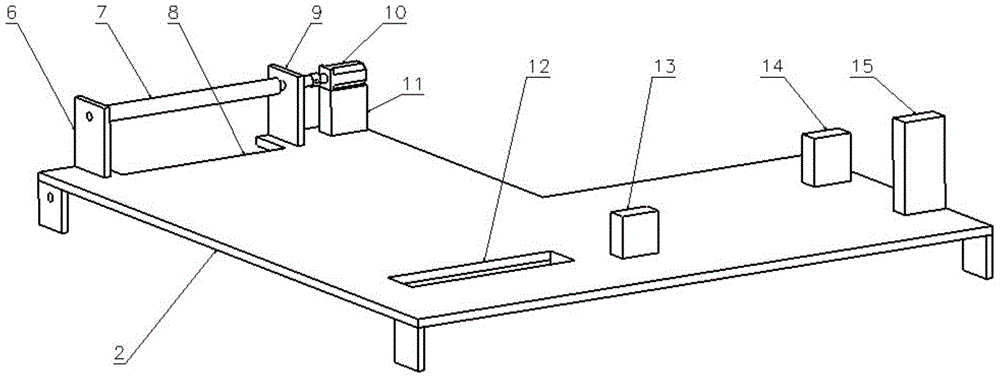

[0085] refer to figure 1 , an automatic loading and unloading test tube labeling machine, mainly composed of a labeling mechanism 1, a bottom plate 2, a feeding mechanism 4 and a feeding cabin 5;

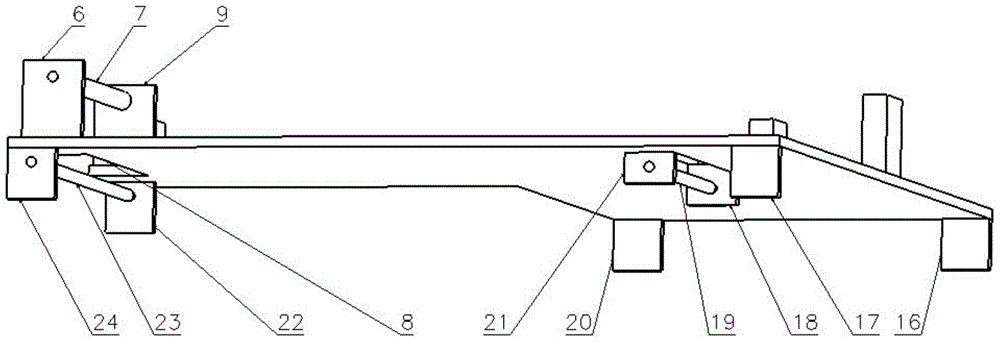

[0086] The labeling mechanism 1 is composed of a turntable mechanism, a label pressing mechanism, a rotary mechanism and a frame assembly.

[0087] refer to Figure 4 , the turntable mechanism is composed of a turntable 34, an intermeshing ring gear 30, a turntable drive gear 32, a turntable drive motor 31 and a drive motor support 13; wherein the turntable 34 is composed of a turntable base body 38 and three identical turntable pressure plates 39 . Cooperate Figure 7 , the turntable base 38 is hollow, and the outside of the turntable base is in the shape of a stepped shaft. There are four outer diameters in total. Bearings are installed at the second largest outer diameter, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com