Fixed-length intermittent propelling machining technology for construction steel pipe

A processing technology and intermittent technology, applied in the field of mechanical processing, can solve the problems of reducing the efficiency of cutting processing and increasing the labor intensity of operators, and achieve the effects of ingenious structure, convenient length and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

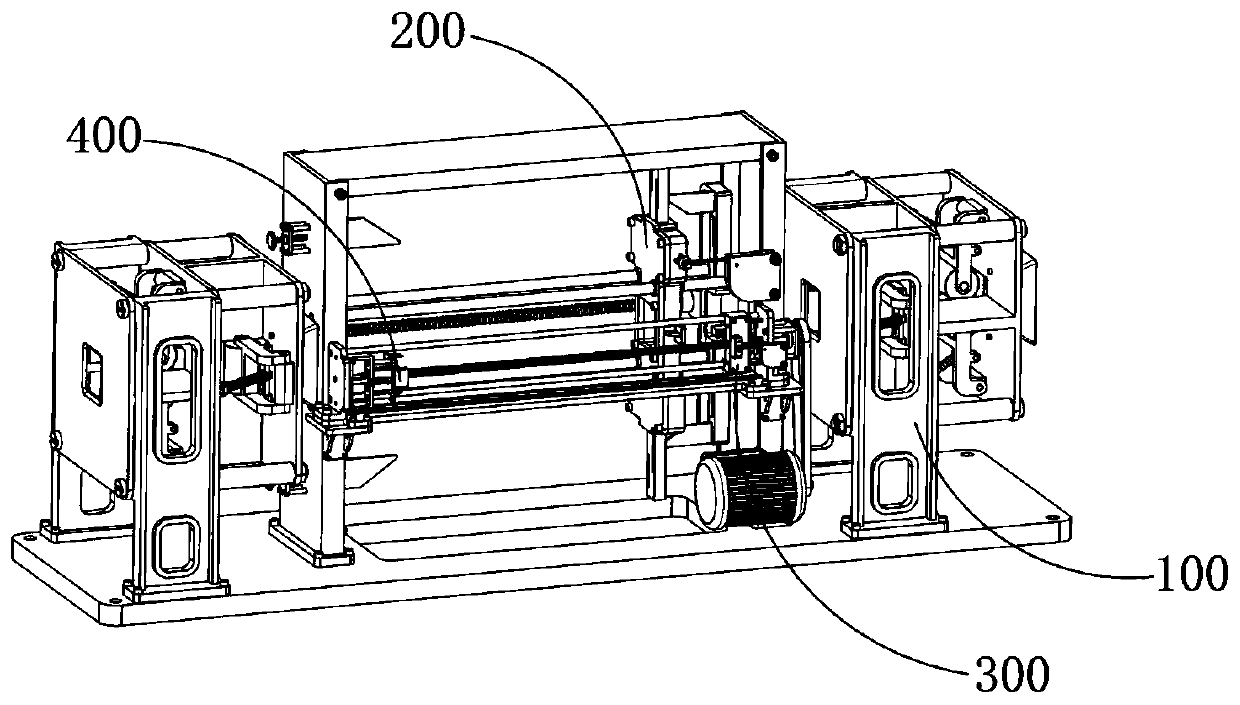

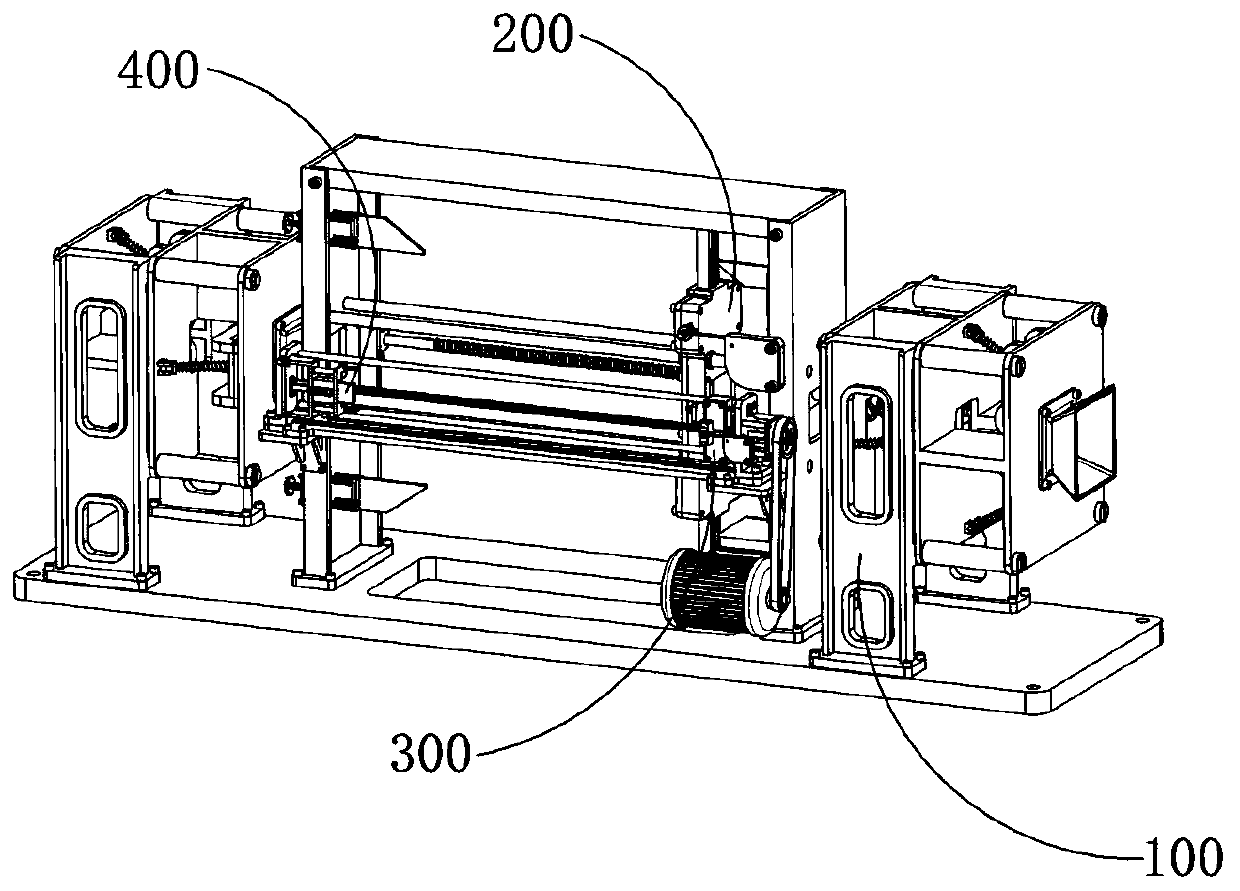

[0057] The fixed-length intermittent advancing processing technology of construction steel pipes, the steps are as follows:

[0058] (1) Docking preparation stage;

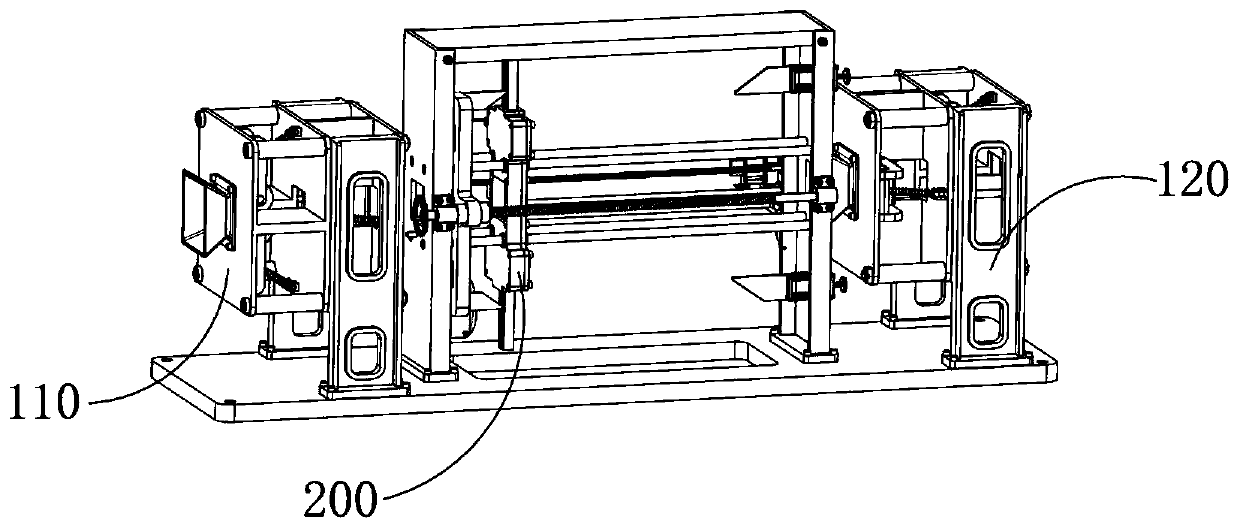

[0059] S1: dock the output end of the output guide mechanism 120 with the feed place of the machining equipment, and then insert the bar from the input end of the input guide mechanism 110 and extend it to the output of the output guide mechanism 120 through the intermittent propulsion device 200 end;

[0060] During the working process of the input guiding mechanism 110 and the output guiding mechanism 120, the operator at first docks the output end of the output guiding mechanism 120 with the feeding place of the machining equipment, and then, the bar is fed from the feeding hopper of the input guiding mechanism 110 132 is inserted, the bar 132 squeezes the limit roller 135 and forces the two limit rollers 135 to overcome the elastic force of the compression spring 138 to separate from each other, and the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com