Intelligent graphene conductive paste RFID electronic tag production line

A technology of conductive paste and electronic label, which is applied in the field of RFID electronic label production line, can solve the problems of bottom film top tightening effect, poor heat dissipation effect, and lack of automatic detection of glue capacity, etc., to increase cooling effect, facilitate circulation, and realize The effect of the water cooling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

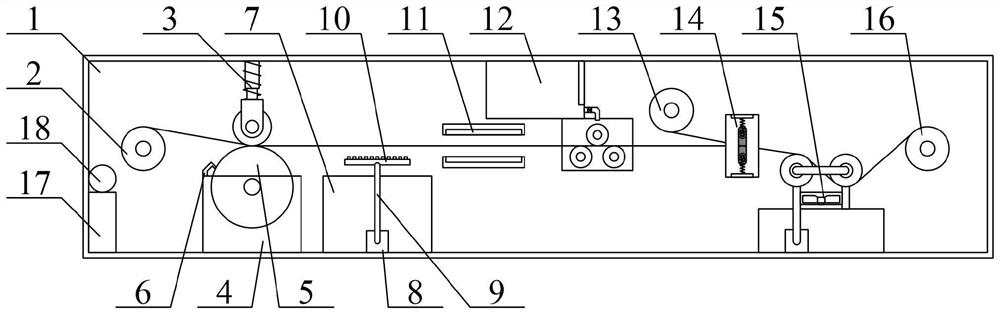

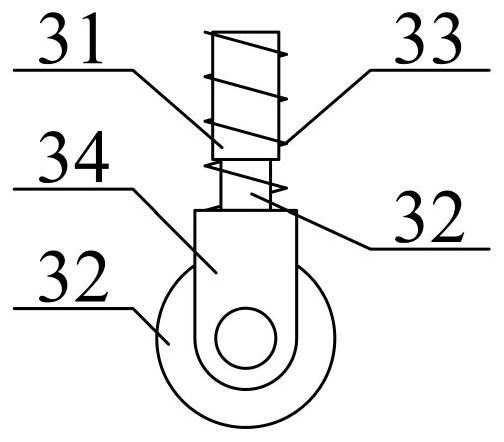

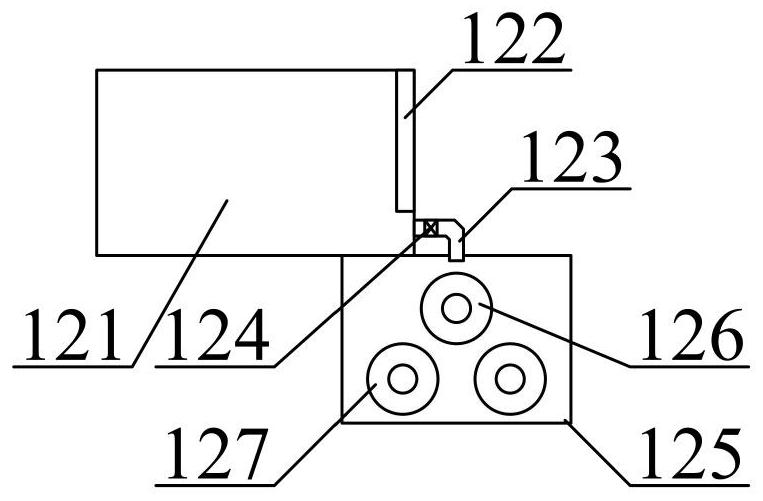

[0040] as attached figure 1 and attached Figure 4As shown, the present invention provides an intelligent RFID electronic label production line of graphene conductive paste, including an installation frame 1, a first film roller 2, a buffering and clamping frame structure 3, a graphene conductive paste storage bucket 4, and a printing roller 5 , auxiliary scraper 6, antioxidant storage bucket 7, antioxidant supply pump 8, antioxidant supply pipe 9, antioxidant nozzle 10, ultraviolet lamp 11, glue adding frame structure 12, second film roller 13, double film Incorporating the auxiliary clamping frame structure 14, strengthening the cooling frame structure 15, the winding roller 16, the controller 17 and the alarm 18, the first film roller 2 is installed on the left side of the installation frame 1; the buffer top The tightening frame structure 3 is installed at the top left position of the installation outer frame 1; the described graphene conductive slurry storage hopper 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com