Replacement and repair process of pile top flange of single pile foundation

A single-pile foundation and flange technology, which is applied in the repair of infrastructure, infrastructure engineering, construction, etc., can solve the problems of poor welding quality, difficulty in replacement and repair work, and affect the welding accuracy of flanges, so as to ensure the firmness of the connection. , Avoid air convection and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

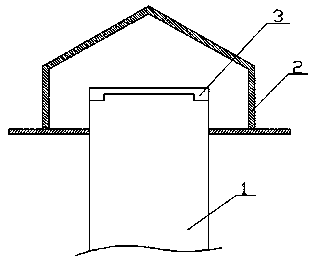

[0071] like figure 1 It shows a single pile foundation pile top flange replacement and repair process, the specific steps are as follows:

[0072] A. Remove the original flange:

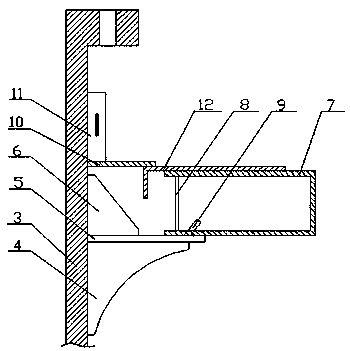

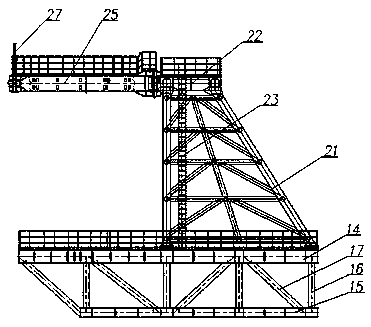

[0073] a. First lift the cage of the single pile foundation, use the pile driving and stabilizing platform device to tighten the pile body, adjust the pile driving and stabilizing platform device, so that the height of the pile driving and stabilizing platform device is 1200mm-1500mm below the top flange of the pile, and then drive the pile The gap between the pile stabilization platform device and the single pile foundation pile body is filled by erecting scaffolding;

[0074] b. Set up a yurt 2 above the pile driving and stabilizing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com