Reinforcement system of cylindrical wood formwork and splice joint fastener

A technology for seam fasteners and wood formwork, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. Reliable guarantee, improve effect, reinforce safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

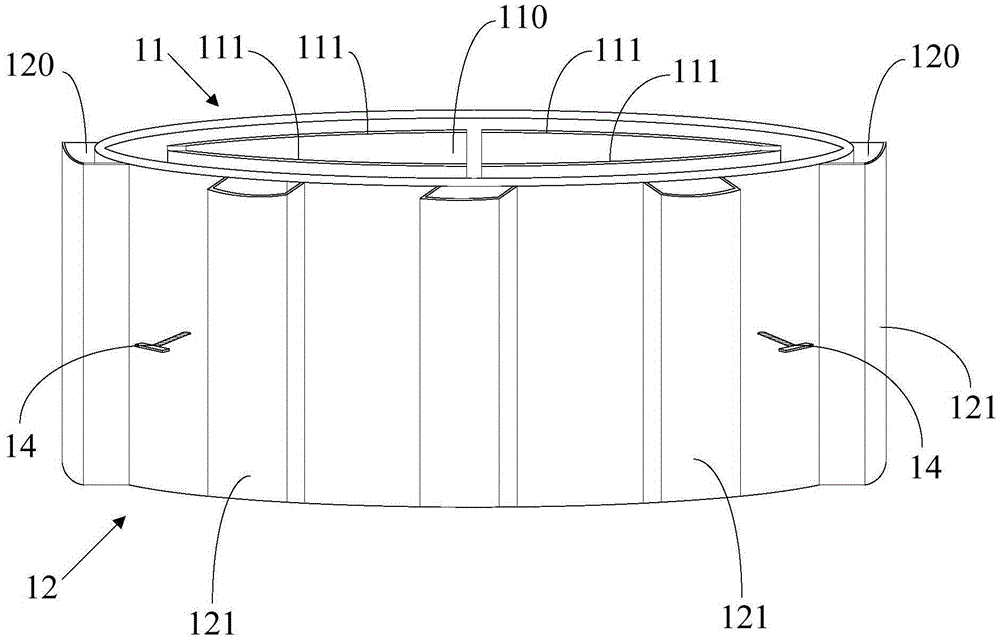

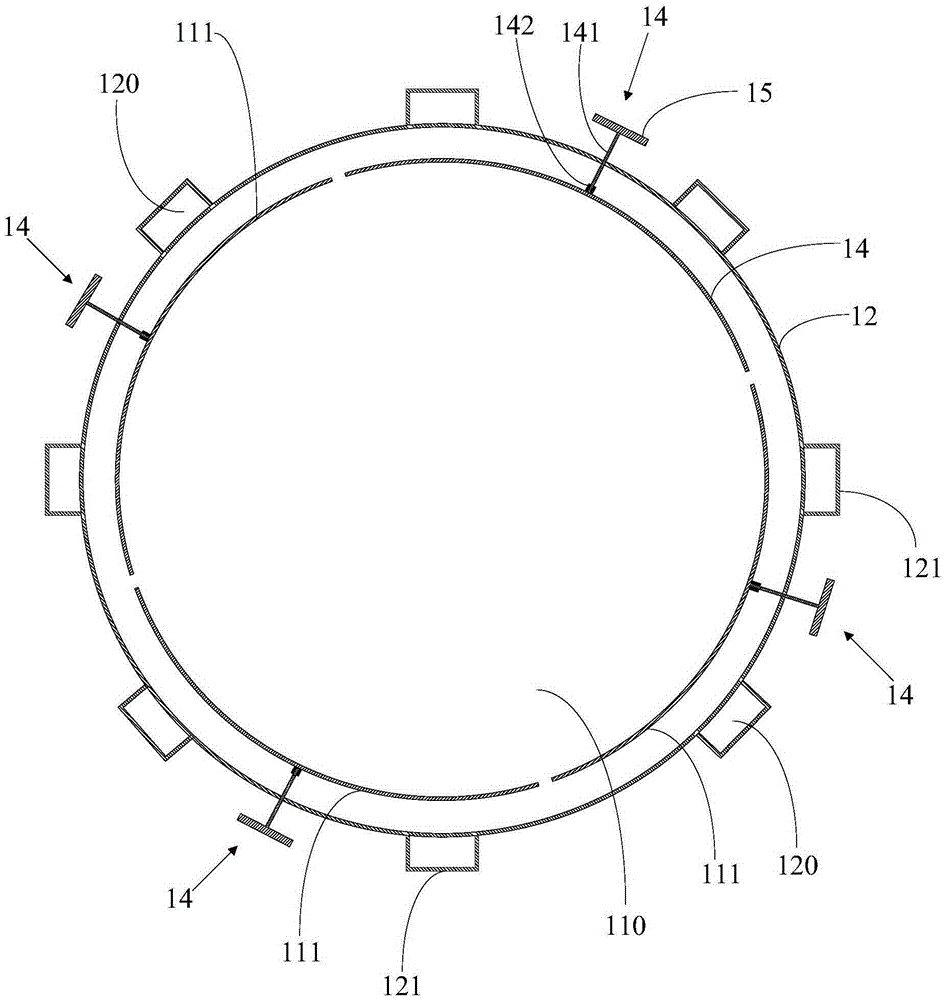

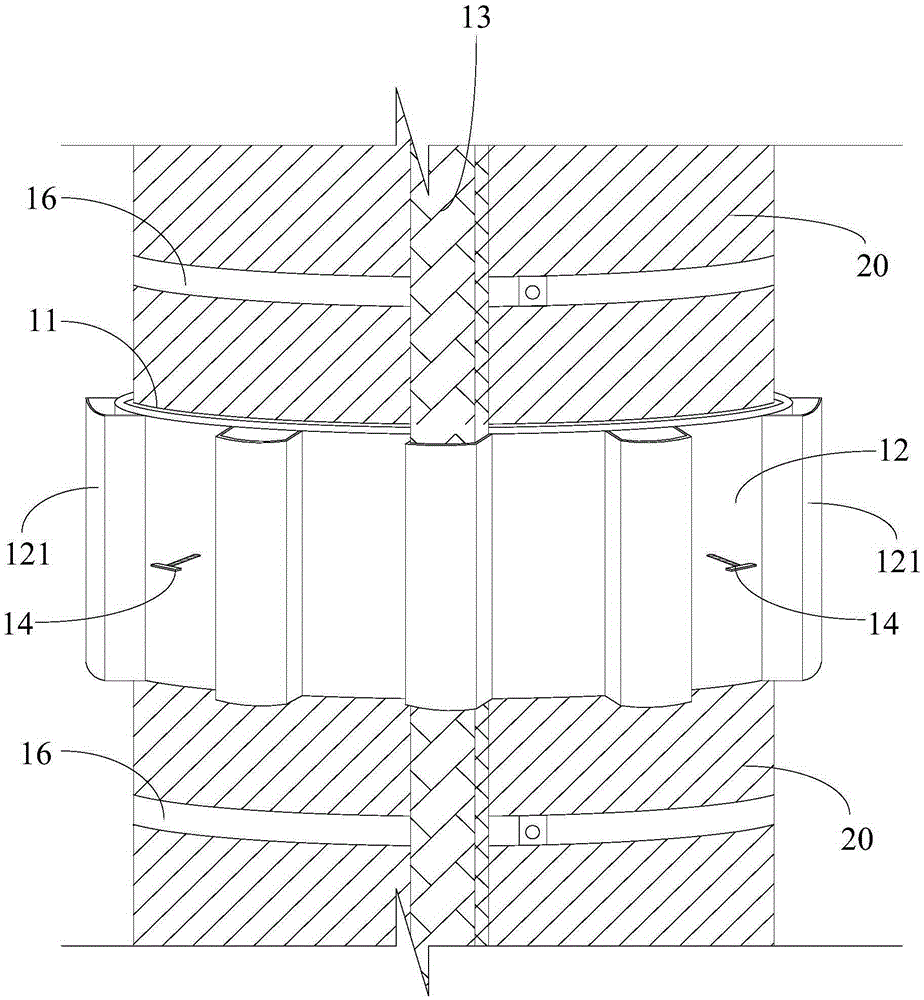

[0024] refer to Figure 1~3 As shown, the joint fastener of the cylindrical wood formwork of the present invention is mainly composed of the inner column hoop 11 and the outer column hoop 12 sleeved on the outside of the inner column hoop 11. Seam position, to solve the problem that the reinforcement and verticality of the joints of the cylindrical wood formwork are not easy to control.

[0025] The inner column hoop 11 is composed of multiple arc-shaped plates 111. The interior of the multiple arc-shaped plates 111 is enclosed to form an accommodating space 110 for the cylindrical wooden formwork 20. The arc-shaped plates 111 are made of 5 mm thick steel plates , with a height of 500 mm. In this embodiment, the inner column hoop 11 is divided into four arc-shaped plates 111 . An adjustment fastening structure 14 for adjusting the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com