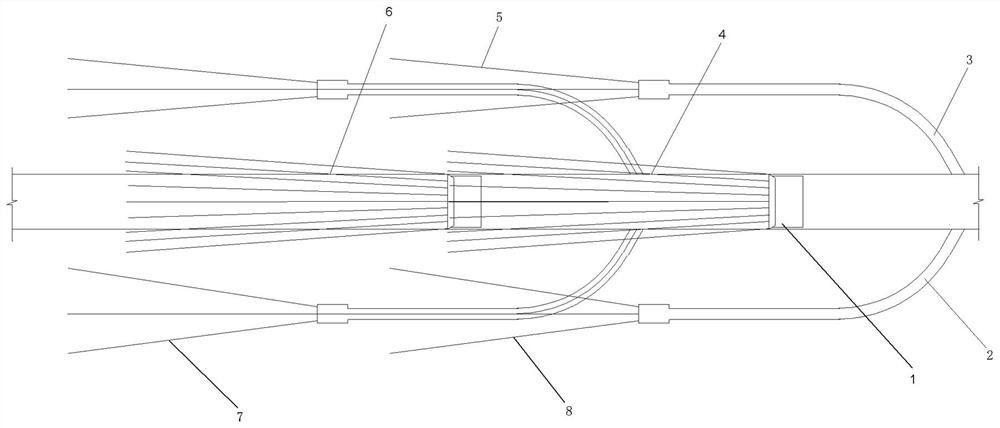

Method for open type TBM to pass through fault fracture zone

A broken zone, open technology, applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problem of easy jamming of fault broken zone, prevent further deterioration of surrounding rock, improve the working environment, avoid damage to tools and The effect of the cutter head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

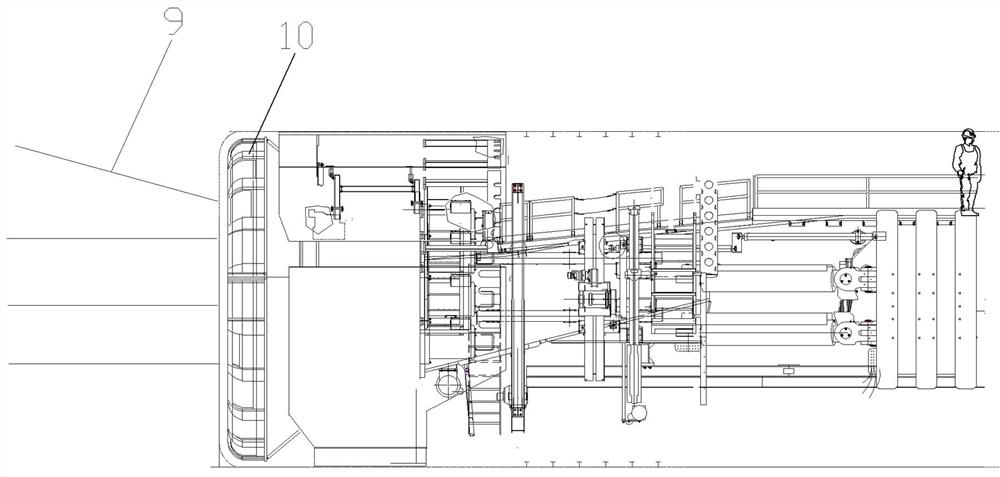

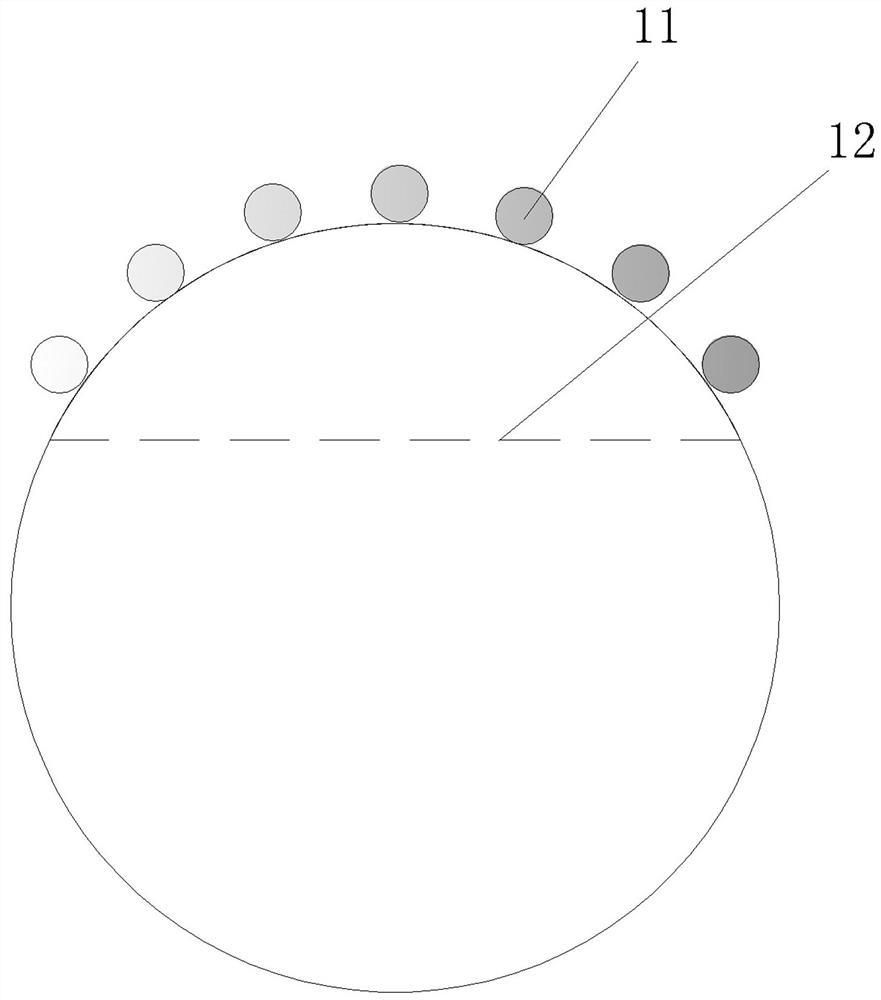

Method used

Image

Examples

Embodiment 1

[0037] On October 21, 2019, when the TBM at the exit of the Gaoligongshan Tunnel reached the mileage D1K221+544.913, the tail of the shield revealed that the rock mass on the left side of the arch waist was strongly weathered and the integrity was poor. The rock mass was broken into blocks and breccias. Water gushed out from the face and tail of the shield, with a maximum water inflow of 150m³ / h. The loose surrounding rock was washed away by the flowing water, and a large amount of slag was entrained and accumulated to the bottom of the tunnel. At the same time, the face of the face and the tail of the shield continued to collapse, and the TBM was forced to shut down.

[0038] After the TBM excavation was blocked, multiple scupper holes were set up on site to reduce the impact of running water on soaking and scouring of the surrounding rock. However, the scupper holes are easily blocked during the drainage process and cannot guarantee long-term effective drainage. In order to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com