Indoor suspended ceiling gusset plate and cladding process thereof

A gusseted and suspended ceiling technology, applied in covering/lining, construction, building construction, etc., can solve the problems of difficult industrial mass production of suspended ceiling gussets, and achieve the effect of clear texture, good environmental performance and full color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

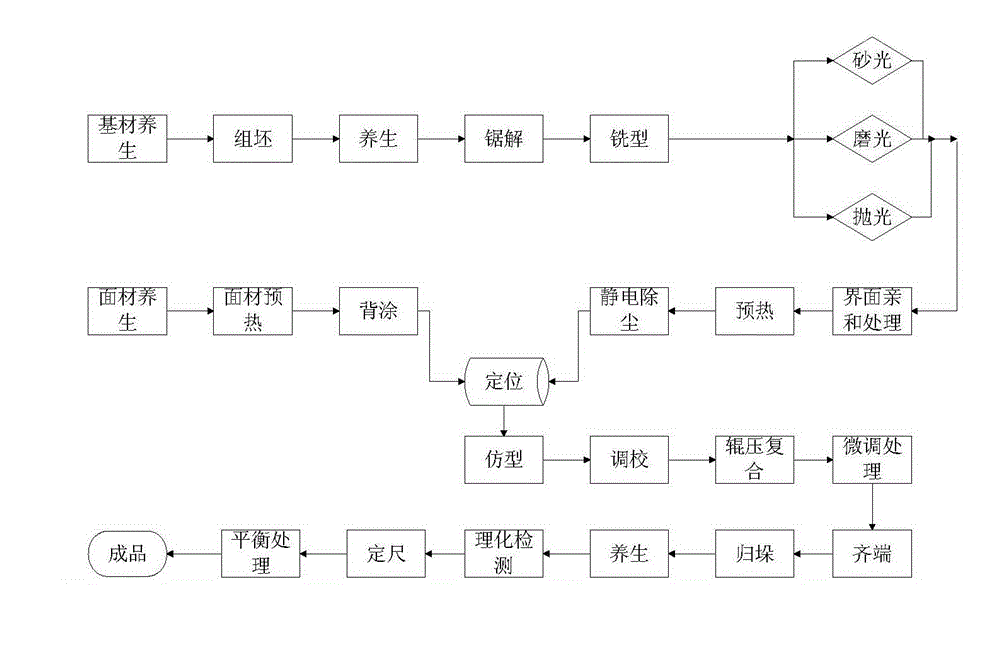

Method used

Image

Examples

Embodiment 1

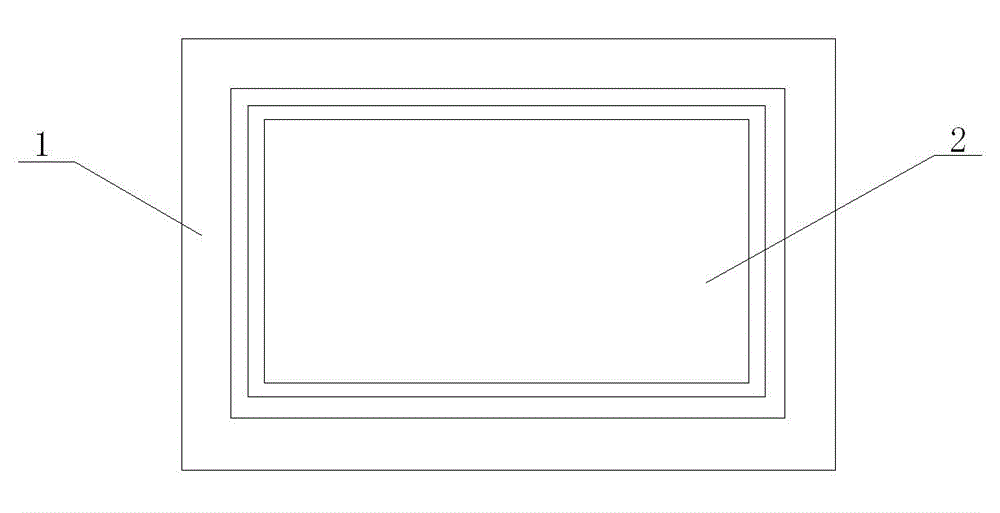

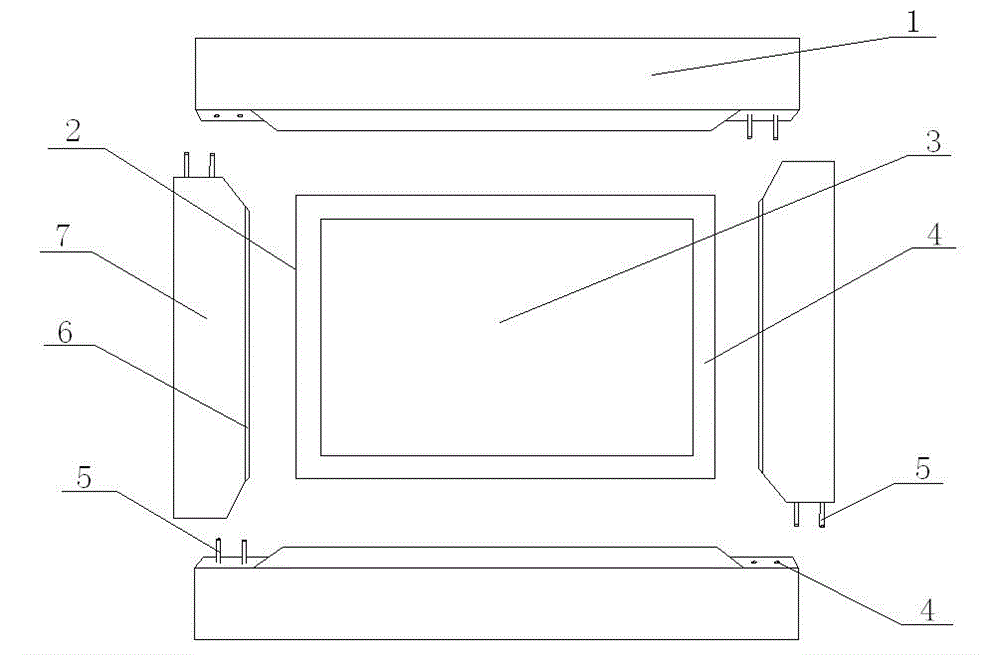

[0035] refer to figure 1 , figure 2 , an indoor ceiling gusset, the ceiling gusset includes a peripheral frame 1 and a core board 2 inside, and the core board 2 is embedded in the frame 1 . The frame 1 is composed of four lines 7 in order to form a rectangular structure, and the adjacent lines are connected by pins. One end of each line is provided with a cylindrical pin 5, and the other end is provided with a cylindrical pin 5. Matching pin holes 4, adjacent lines are spliced into one body through cylindrical pins 5 and pin holes 4; the frame 1 and the core board 2 are clamped.

[0036] The inner side of the frame is provided with a groove 6, and the periphery 4 of the core plate is inserted into the groove 6, and the thickness of the periphery 4 of the core plate is smaller than the thickness of the center 3 of the core plate.

[0037] The surface of the frame is covered with a mask layer with texture and color structure, and the frame and the mask layer are bonded by a...

Embodiment 2

[0045] refer to figure 1 , figure 2 , an indoor ceiling gusset, the ceiling gusset includes a peripheral frame 1 and an inner core board 2, the core board 2 is embedded in the frame 1. The frame 1 is composed of four lines 7 in order to form a rectangular structure, and the adjacent lines are connected by pins. One end of each line is provided with a cylindrical pin 5, and the other end is provided with a cylindrical pin 5. Matching pin holes 4, adjacent lines are spliced into one body through cylindrical pins 5 and pin holes 4; the frame 1 and the core board 2 are clamped.

[0046] The inner side of the frame is provided with a groove 6, and the periphery 4 of the core plate is inserted into the groove 6, and the thickness of the periphery 4 of the core plate is smaller than the thickness of the center 3 of the core plate.

[0047] The surface of the frame is covered with a mask layer with texture and color structure, and the frame and the mask layer are bonded by an adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com