Building block material unit and butt joint structure thereof

A technology of building blocks and masonry, which is applied to building components, building structures, buildings, etc., and can solve problems such as the inability to guarantee the quality of core column concrete pouring, the inability to ensure the tightness of joints between corner core columns and straight wall core columns, etc. , to ensure the pouring quality, increase the scope of application, and eliminate safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

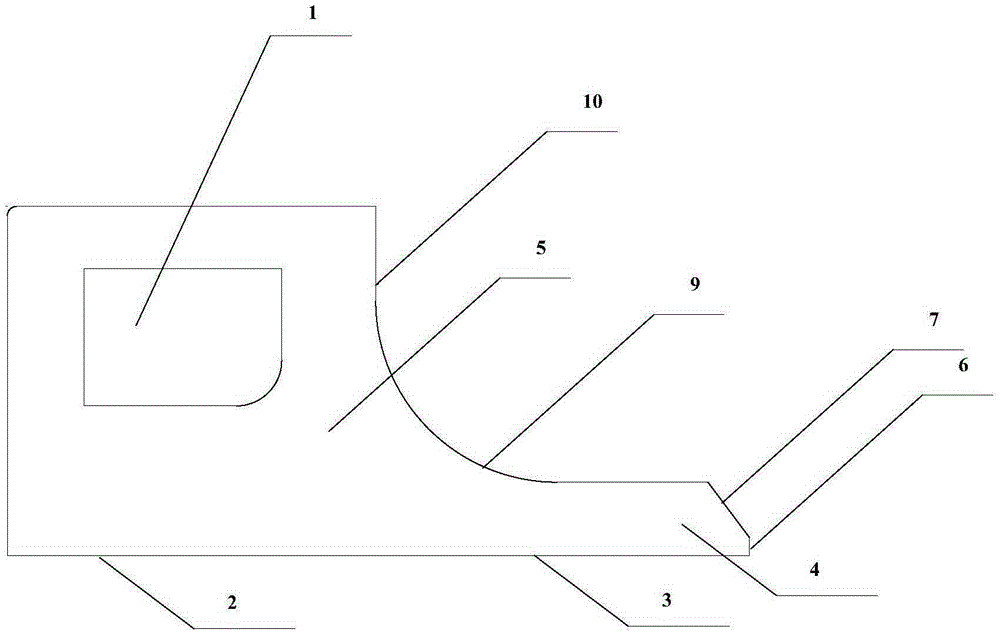

[0039] Such as Figure 1-3 As shown, the building block material unit of the present invention includes two adjacent hollow masonry 1 formed by connecting side plates, and extends outward along the side plate 2 of the hollow masonry to form a concrete side plate formwork 3 .

[0040] The concrete side panel form 3 has an outer end 4 and an inner root 5, and the outer end has a first side panel 6 of the concrete side panel form and a second side panel 7 of the concrete side panel form, the first side panel of the concrete side panel form The included angle α between 6 and the horizontal line is 90 degrees, and the included angle β between the second side plate 7 of the concrete side panel form and the horizontal line is 45 degrees.

[0041] The inner root 5 of the concrete side plate form extends to the hollow masonry 1 and is thickened so that the inner arc range of the adjacent hollow masonry 1 is R20-R100mm.

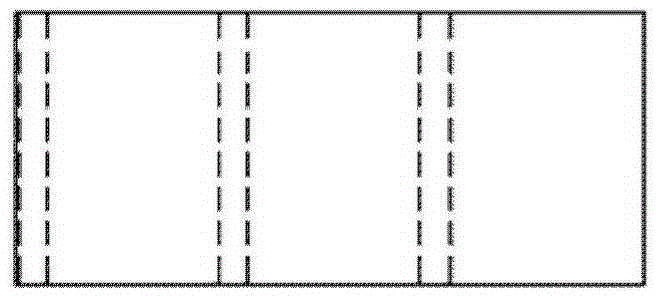

[0042] There are 1-2 through holes inside the hollow masonry, wh...

Embodiment 2

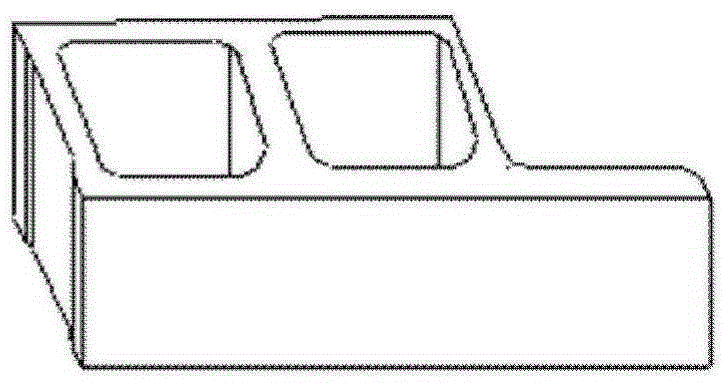

[0045] Such as Figure 4As shown, in the right-angle butt joint structure of building blocks of the present invention, when docking, two building blocks are relatively placed, and the second side plate 7 of the concrete side plate form and the third side of the concrete side plate form of one of the building blocks are The board 9 and the third side board 10 of the hollow masonry are sequentially combined with the second side board 7 of the concrete side board form of another building block, the third side board 9 of the concrete side board form and the third side board 10 of the hollow masonry docking.

[0046] The space formed by the right-angle butt joint structure of the building blocks is used to contain the space for the steel and concrete of the core column.

[0047] There are two through holes inside the hollow masonry for the installation of reserved pipes for water and electricity.

Embodiment 3

[0049] Such as Figure 4 As shown, in the right-angle butt joint structure of building blocks of the present invention, when docking, two building blocks are relatively placed, and the second side plate 7 of the concrete side plate form and the third side of the concrete side plate form of one of the building blocks are The board 9 and the third side board 10 of the hollow masonry are sequentially combined with the second side board 7 of the concrete side board form of another building block, the third side board 9 of the concrete side board form and the third side board 10 of the hollow masonry docking.

[0050] The space formed by the right-angle butt joint structure of building blocks is used to hold the core column steel and concrete.

[0051] There are two through holes inside the hollow masonry for the installation of reserved pipes for water and electricity. When arranging water pipes, such as Figure 5 As shown, the pavement can be completed by using the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com