Adjusting type light movable formwork support and steel formwork capable of guaranteeing tightness of joint of new concrete and old concrete of lock chamber

A steel formwork and adjustable technology, applied in ship locks, ship lifting devices, climate change adaptation, etc., can solve the problems of slurry leakage, rotten roots, etc., and achieve the effect of tight joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

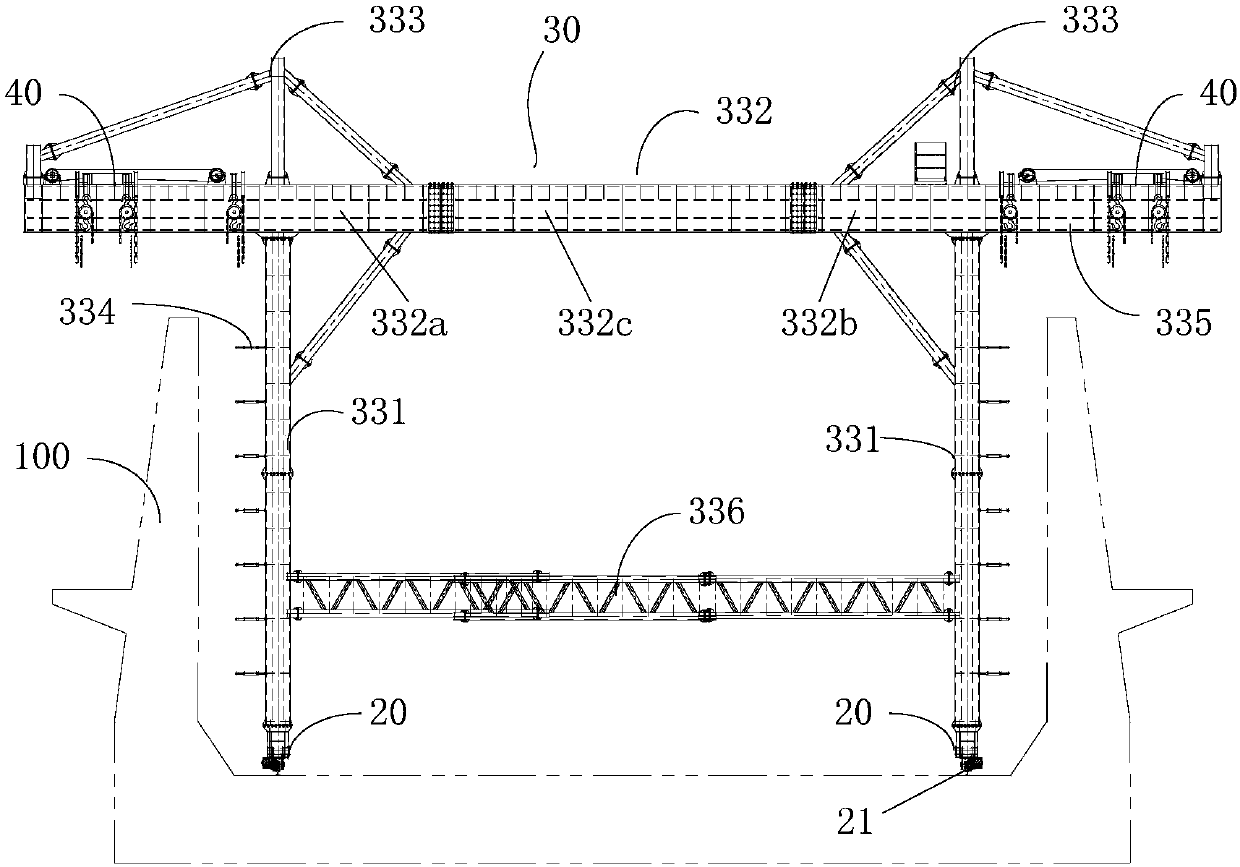

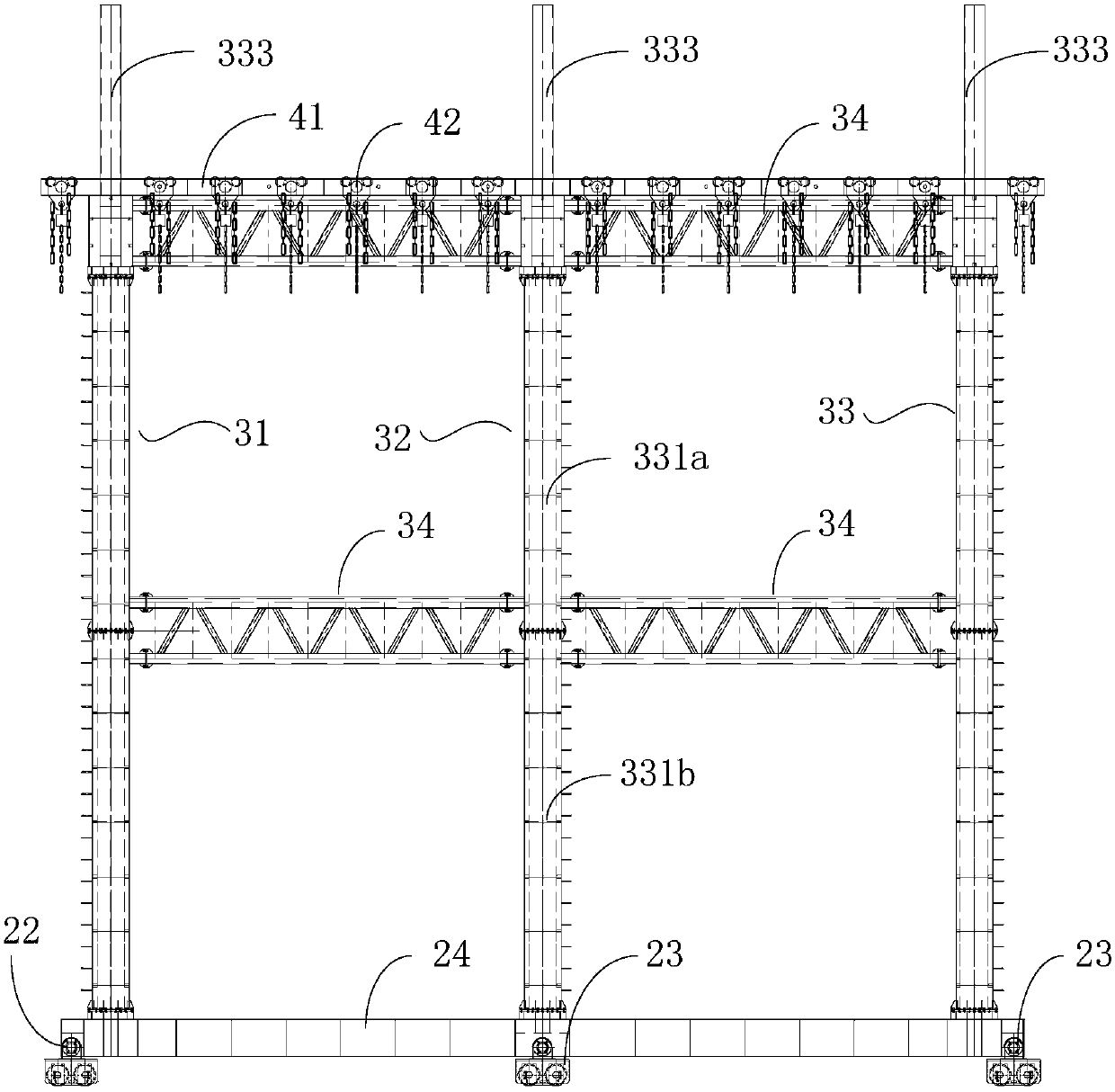

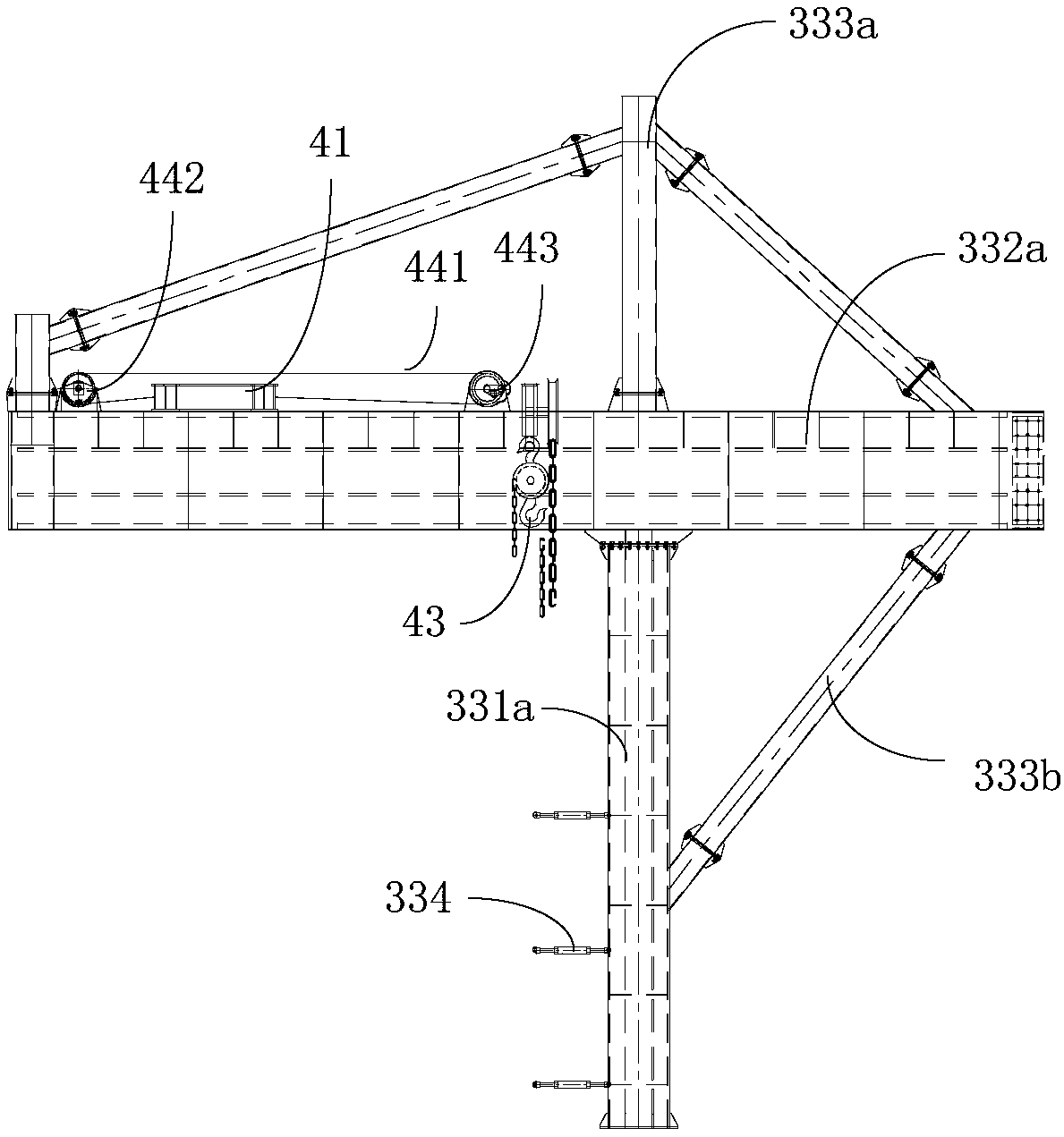

[0031] figure 1 and Figure 13 Some embodiments according to the invention are shown.

[0032] combined reference figure 1 and figure 2 , The lightweight mobile formwork of the present invention is mainly composed of a steel formwork system, a trolley system 20, a box-shaped support system 30, and a suspension system 40.

[0033] Wherein, the above-mentioned steel formwork system includes an inner formwork and an outer formwork, and its structure is: a formwork panel, a laminated panel transverse rib, a vertical back rib, and a stiffening beam along the direction of the gate wall.

[0034] In one embodiment, formwork panel: 6mm thick steel plate; veneer panel transverse rib: 10# channel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com