Method for making spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood

A technology of fair-faced concrete and structural formwork, which is applied in the fields of formwork/formwork components, building structures, and on-site preparation of building components, and can solve the problems of uneven and beautiful surface of fair-faced concrete structures, difficulty in manufacturing and installation, and the use of supporting steel pipes Large volume and other problems, to achieve the effect of smooth surface of fair-faced concrete structure, convenient construction, and small usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

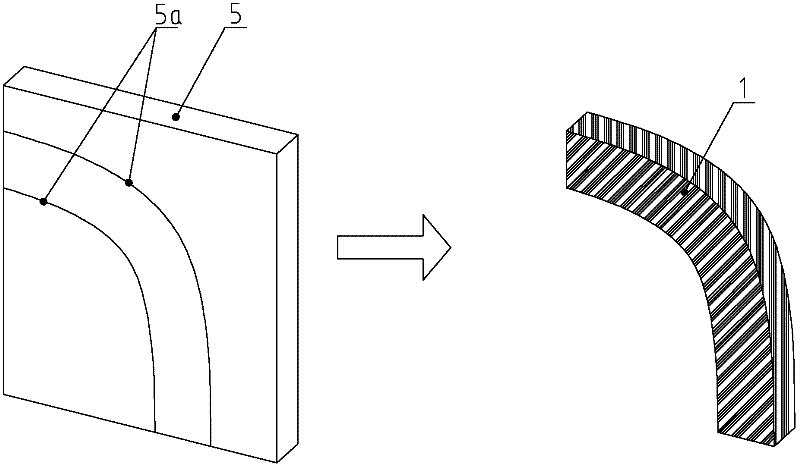

[0027] Taking the diving platform as an example below, the present invention will be described in detail. The method for making space multi-curved surface fair-faced concrete structure formwork with wooden splint of the present invention, it carries out according to the following steps:

[0028] 1. Create a 3D model

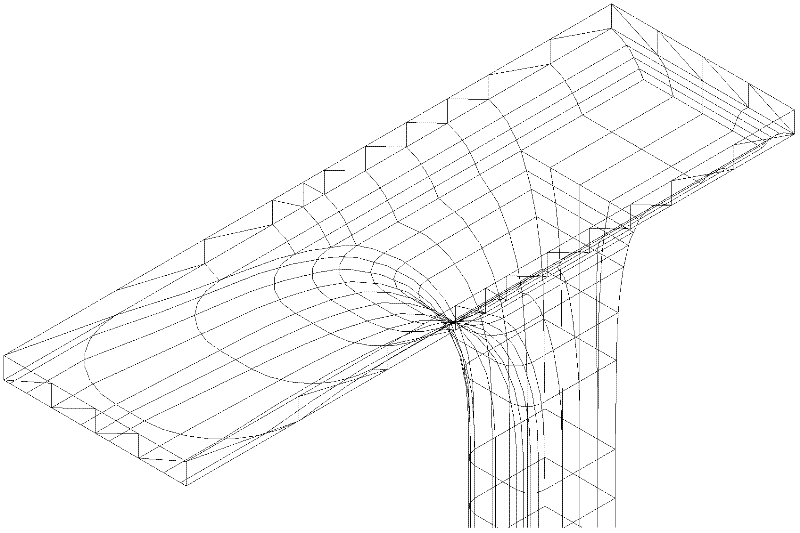

[0029] According to the known arc radii of different heights in the construction drawings, the three-dimensional model of the space multi-curved fair-faced concrete structure (that is, the diving platform) is established in the CAD software according to the actual size.

[0030] 2. Formwork stress analysis

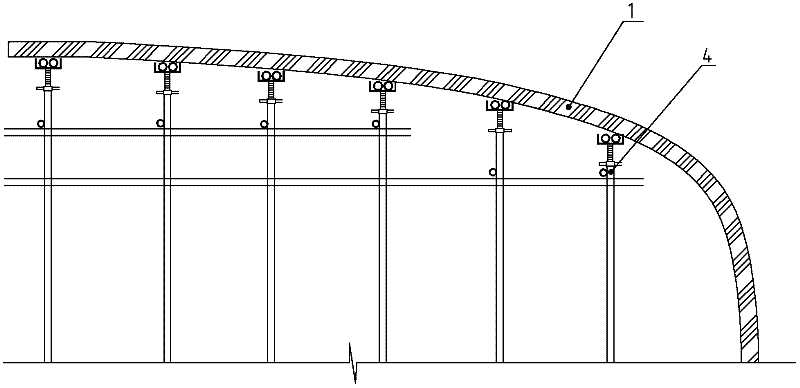

[0031] According to the above three-dimensional model, the stress analysis of concrete is simulated in the computer, and the backing keel is arranged according to the analysis results. The greater the stress on the bottom formwork, the smaller the backing keel spacing, and vice versa, so that the stress on the backing keel and the bottom formwork is greater....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com