Gear wheel with changed tooth height

A technology of changing tooth height and gears, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., to achieve the effect of improving bending bearing capacity, reducing noise, and protecting machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

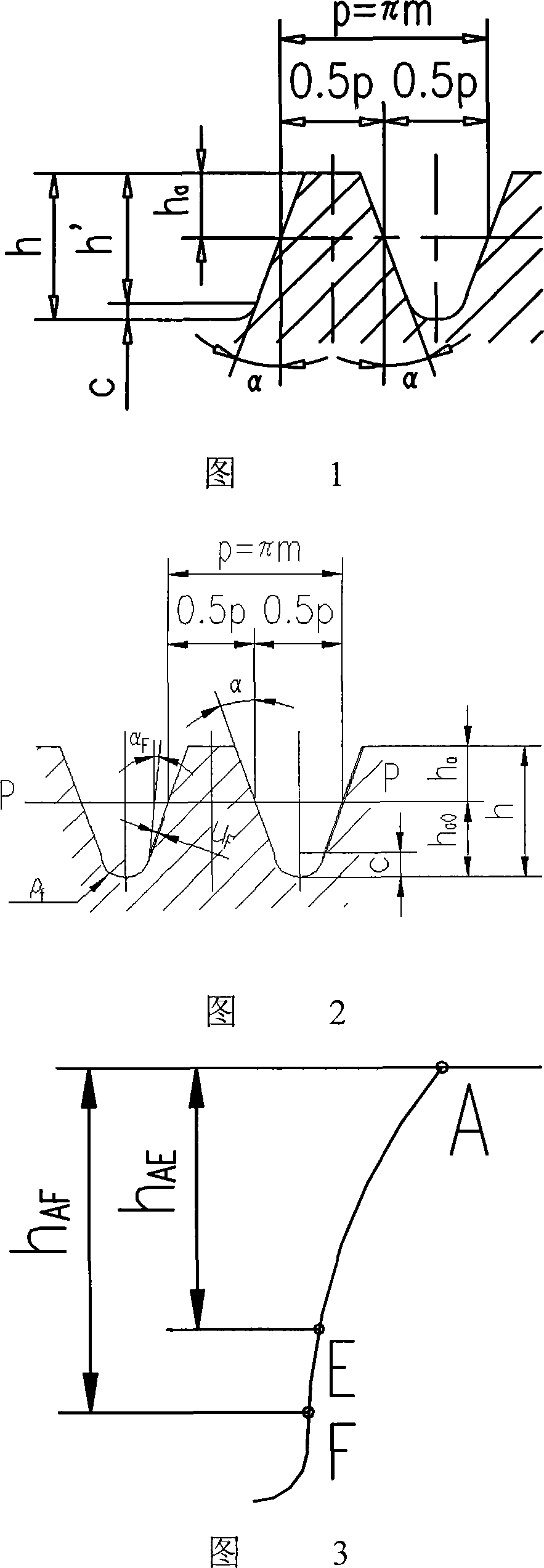

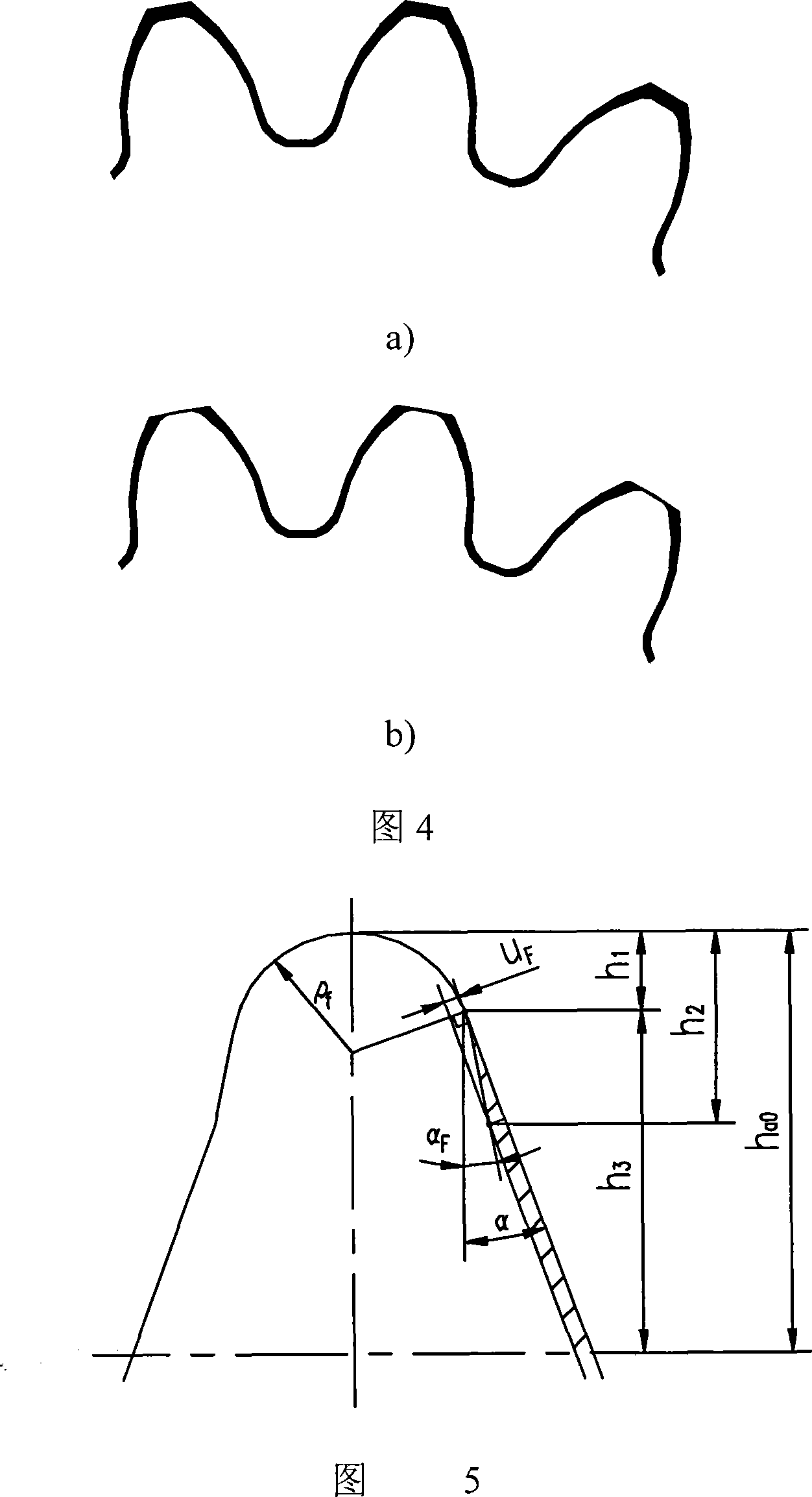

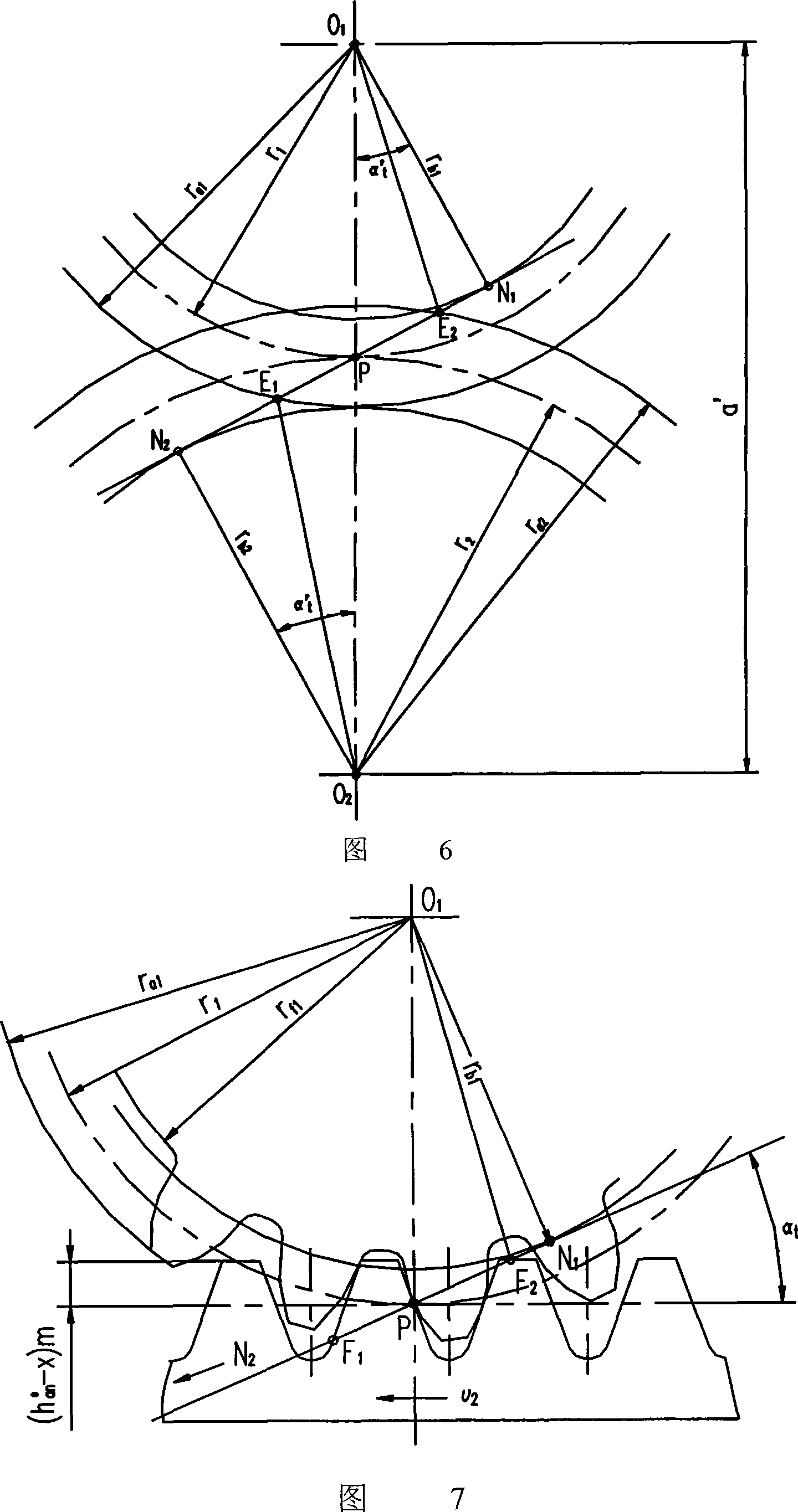

Method used

Image

Examples

Embodiment 1

[0111] This embodiment is a pair of carburized and quenched ground gears. The parameters are: modulus m=5mm, number of teeth z1=29, z2=89, center distance a’=325mm, helix angle β=22.5°, addendum height coefficient han * =1, headspace coefficient C n * = 0.4, the displacement coefficient x1 of the pinion = 0.572, the displacement coefficient of the large gear x2 = 0.6289, the tooth width b = 125mm, the following steps can be followed to design a variable tooth height gear:

[0112] (1) Calculate the gear parameters and related values of the original standard size. Get:

[0113] The pitch circle diameters of small and large gears d1=156.947mm, d2=481.665mm;

[0114] Addendum circle diameter of small and large gears da1=172.046mm, da2=497.333mm;

[0115] The dedendum circle diameters of small and large gears df1=148.667mm, df2=473.954mm;

[0116] The usable involute height h of the pinion produced by processing the rack tool with the addendum height coefficient of 1 F1 =9.4...

Embodiment 2

[0145] This embodiment is a pair of quenched and tempered hobbing gears, the parameters are: modulus m=9mm, number of teeth z1=18, z2=70, center distance a’=415mm, helix angle β=10°, addendum height coefficient han * =1, headspace coefficient C n * = 0.25, the displacement coefficient x1 of the pinion = 0.722, the displacement coefficient of the large gear x2 = 0.8627, the tooth width b = 190mm, the following steps can be followed to design a variable tooth height gear:

[0146] (1) Calculate the gear parameters and related values of the original standard size. Get:

[0147] The pitch circle diameters of small and large gears d1=164.499mm, d2=639.719mm;

[0148] Addendum circle diameter of small and large gears da1=192.754mm, da2=670.505mm;

[0149] The dedendum circle diameters of small and large gears df1=154.995mm, df2=632.747mm;

[0150] The usable involute height h of the pinion produced by processing the rack tool with the addendum height coefficient of 1 F1 =16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com