Deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method

A technology for steel pipe concrete piles and deep mixing piles, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., and can solve the problems of damage, bending resistance, shear resistance, overturning resistance and slip resistance, which affect the safety of foundation pit buildings and other issues, to achieve short construction period, improve anti-overturning and anti-sliding ability, and favorable effects of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

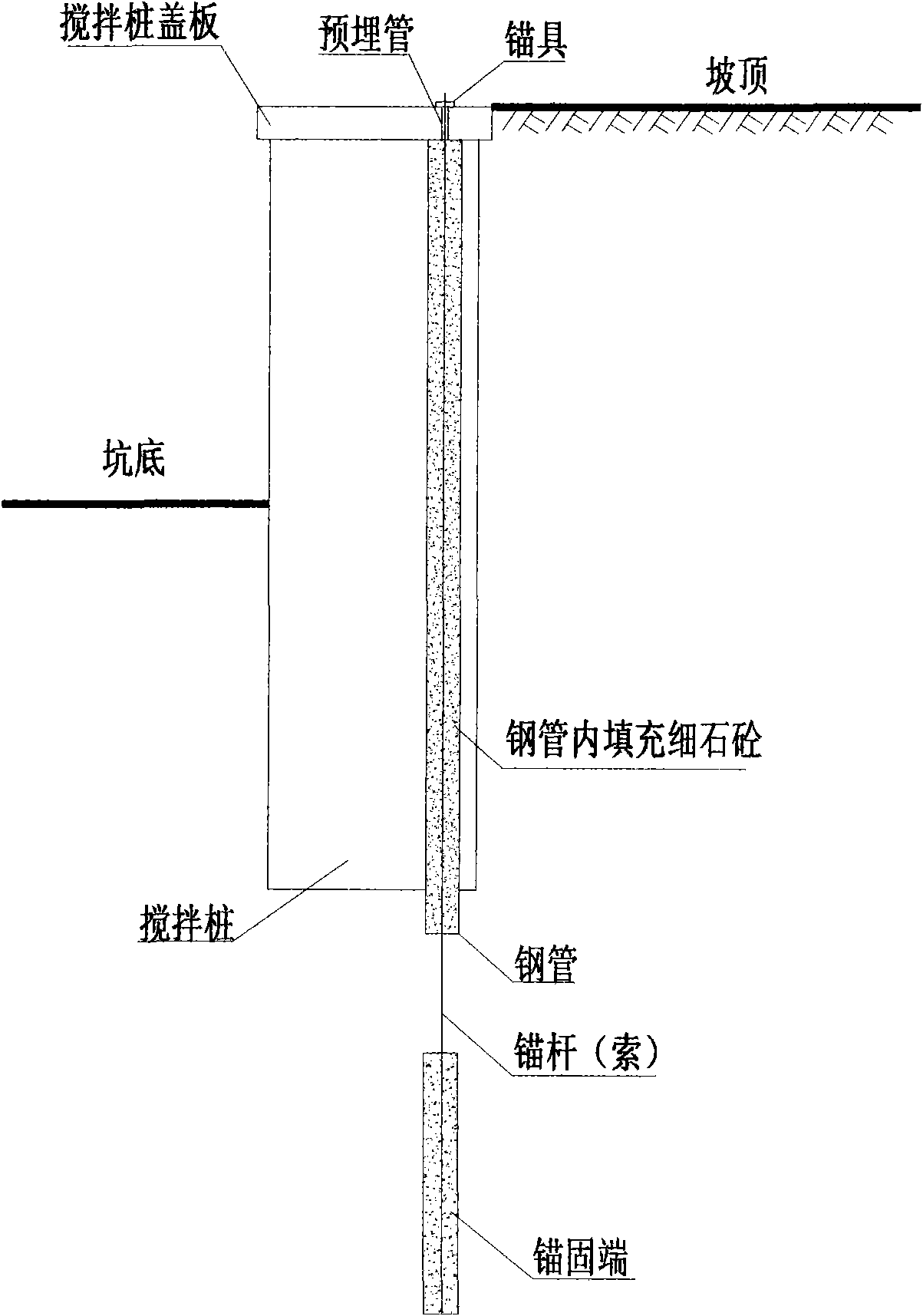

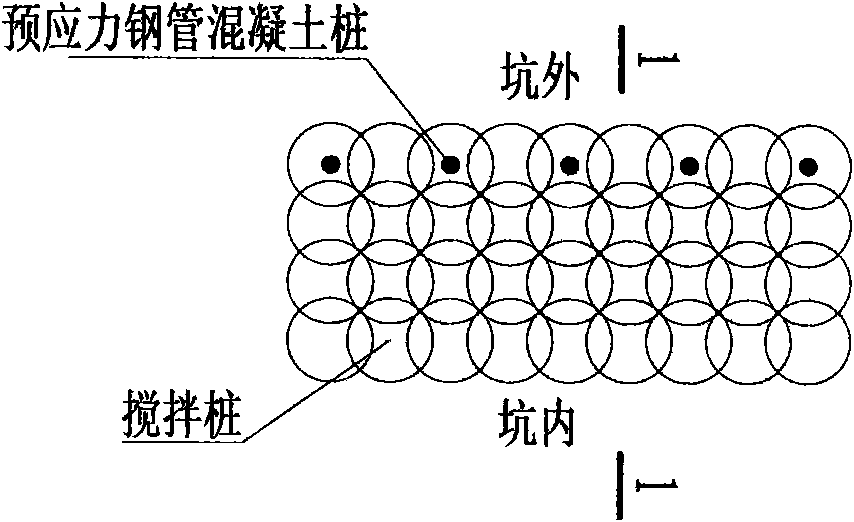

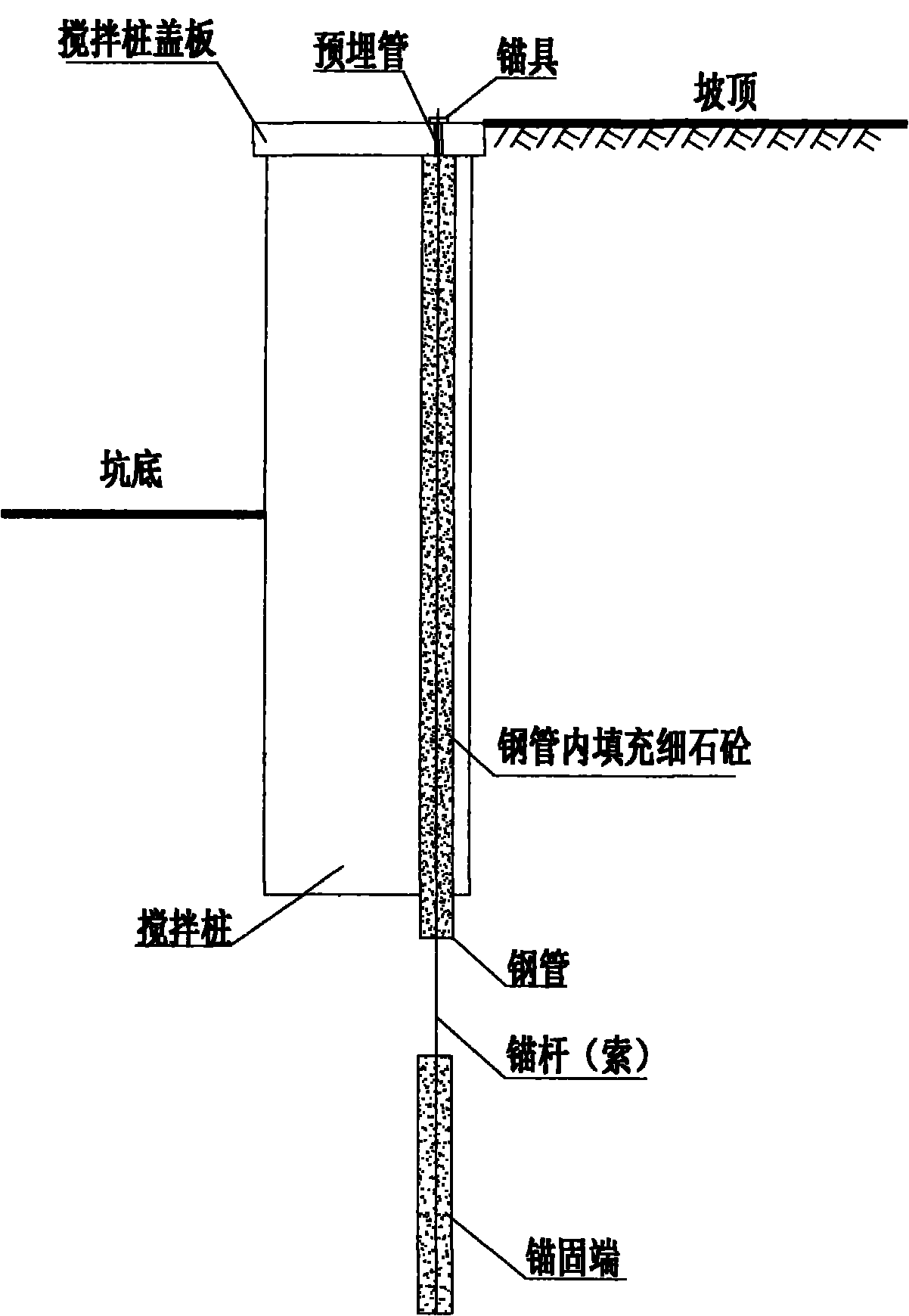

[0015] according to figure 1 , figure 2 As shown, a deep mixing pile + micro prestressed steel pipe concrete pile + vertical anchor bolt composite foundation pit support method, the steps are as follows:

[0016] 1. Construction of deep mixing piles;

[0017] 2. Within 12 hours after the construction of the deep mixing pile, use an engineering drilling rig to form a hole in the mixing pile, insert the ribbed steel bar into the soil layer at the anchoring end, and perform grouting at the anchoring end;

[0018] 3. After the slurry is solidified, put the round steel pipe on the ribbed steel bar and insert it into the bottom of the deep mixing pile through the inner hole of the mixing pile. After pouring the concrete cover plate and solidifying, the ribbed steel bar is stretched to apply prestress and locked with the anchor, and then to the circular Grout is poured into the steel pipe to form a miniature prestressed steel pipe concrete pile.

[0019] The outer diameter of the...

Embodiment 2

[0021] according to figure 1 , figure 2 As shown, a deep mixing pile + micro prestressed steel pipe concrete pile + vertical anchor bolt composite foundation pit support method, the steps are as follows:

[0022] 1. Construction of deep mixing piles;

[0023] 2. Within 12 hours after the construction of the deep mixing pile, use an engineering drilling rig to form a hole in the mixing pile, insert the steel hinge line into the soil layer at the anchoring end, and perform grouting at the anchoring end;

[0024] 3. After the slurry is solidified, put the square steel pipe on the steel hinge line and insert it into the bottom of the deep mixing pile through the inner hole of the mixing pile. After pouring the concrete cover plate and solidifying, stretch the steel hinge line to apply prestress and lock it with anchors, and then install it in the direction Fine stone concrete is poured into the steel pipe to form a micro prestressed steel pipe concrete pile.

[0025] The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com